24

3.13 Water Softener (if fitted)

The Water Softener uses a softening material (resin) to prevent most of the elements that cause hard water

from being present in the wash water. The resin can only treat a limited amount of water before it needs to be

regenerated. Regeneration is achieved by pumping salty water (brine) through the resin, and ushing away the

hard elements to the drain. The process of delivering softened water, and regeneration of the resin is controlled

by the electronic controller.

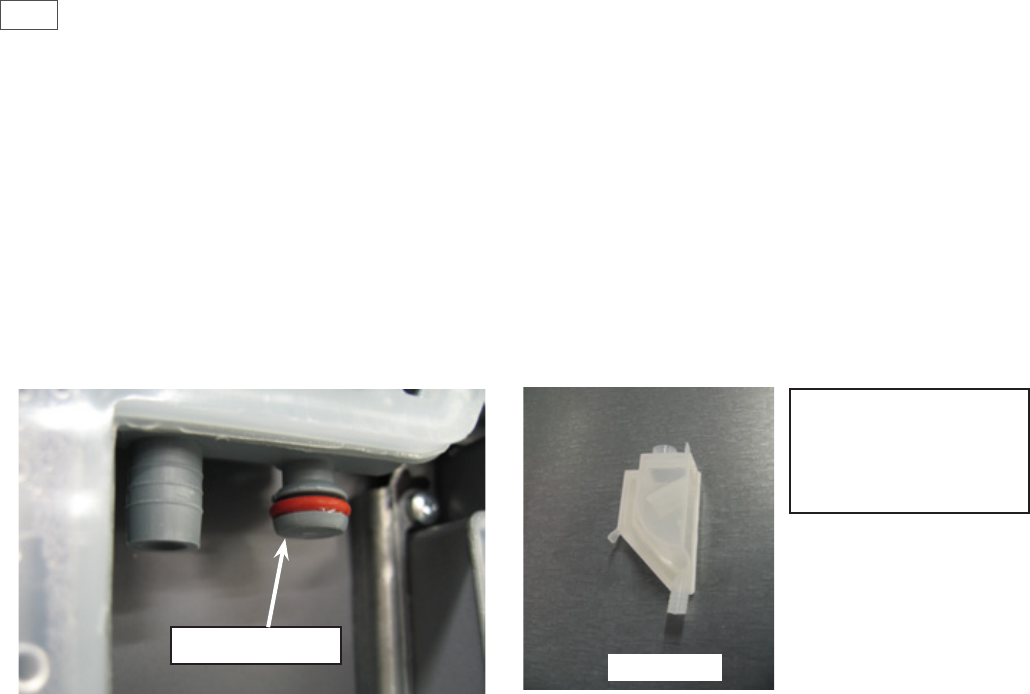

Delivering Softened Water: - Supply water arrives from the inlet valve then through an inline Strainer to remove

large deposits. The strainer is attached to the water softener by an inlet spigot.

In the water softener the water passes through an air break and a diverter valve. It is then either directed

through the resin to the dispenser as softened water, or directly to the dispenser, then into the tub.

The electronic controller measures the volume of water treated soft water, and adds an appropriate amount of

non-treated hard water, to deliver a mix that is at the required hardness according to a pre-determined schedule.

Water is treated according to its supply hardness. The customer is able to select one of 5 supply hardness settings

in option adjustment mode.

Regeneration:- Regeneration is triggered when the amount of water that has been treated since the last

regeneration nears the capacity of the water softener. The quantities treatable for each of the ve settings

of supply hardness have been predetermined, and are stored in the electronic controller. When triggered,

immediately after lling for the main wash, the brine pump is activated and delivers a volume of salty water

into the resin, at an amount appropriate to the hardness setting. The frequency of the pump is 3 Hz, and makes

a slight rattling sound. Later in the wash cycle, the resin is ushed with supply water, and the by-products of

regeneration are delivered into the wash water, and drained with it away to waste. During the ush the ll valve

turns on and o alternately for 5 seconds for a number of times depending on the hardness setting. Normal

treatment of incoming water then resumes.

Salt:- The customer is required to ll the salt tank with dishwashing salt from time to time. Salt is used in the

water softener by mixing it with water to produce the salty water (brine) used in regeneration. When the salt

level is low, a salt level detector causes a glowing red light to appear in the salt bung, and a “Salt” symbol appears

in the LCD if one is tted. When this happens, the customer should remove the salt bung, and using the salt

container provided, pour salt into the salt reservoir until salt can be seen at the opening. The “Salt” symbol on

the LCD will disappear and the red light will not be visible when the salt tank bung is replaced. In areas where

the supply water is moderately hard, 21 dH (degrees of hardness) or 375 parts per million, water softener setting

3) the salt reservoir will need to be lled about once a month, and in harder areas more frequently. Delivery of

treated water from one ll of the salt reservoir:

240 litres at 30 – 100 ppm from 375 ppm supply water (setting 3)

144 litres at 30 – 100 ppm from 625 ppm supply water (setting 5)

NOTE: The strainer is

a replaceable part,

and must be replaced if

blocked.

Strainer Spigot

Strainer