40

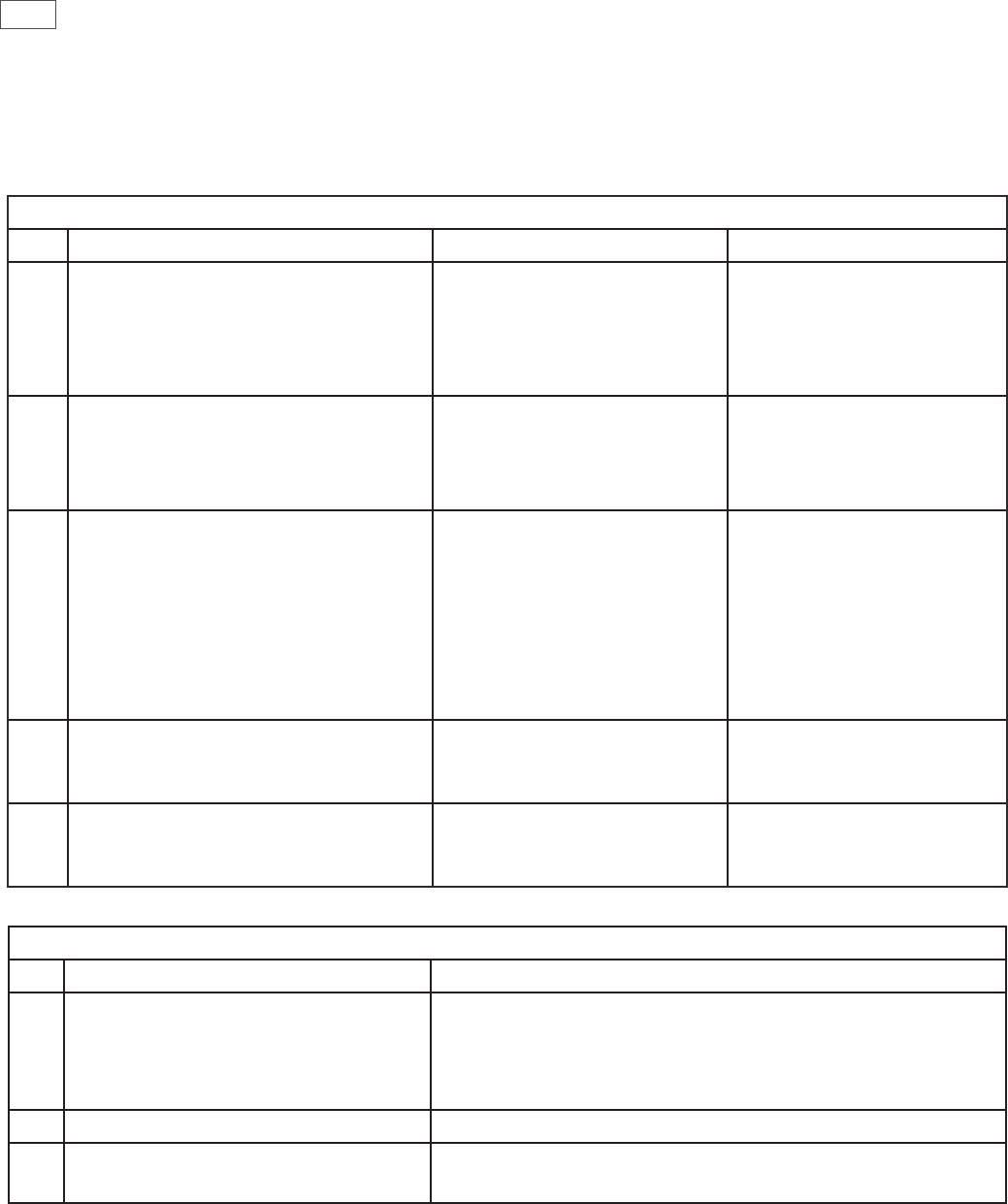

Poor Dry Performance (Non Vented)

QUESTION YES NO

1 Is the customer complaining of

plastic items not drying?

Advise customer that due

to plastics having a low

thermal mass, these items

give inherently bad drying

performance.

Go to Question 2.

2 Is the customer using rinse aid? Go to Question 3, Advise customer that

the use of rinse aid

will improve dry

performance.

3 Is the customer using Fast or Eco

cycles?

Advise customer that

due to lower nal rinse

temperatures, dry

performance is comprised

when using Fast and Eco

cycles (there is less residual

heat for drying at the end

of cycle).

Go to Question 4

4 Is the rinse aid setting high

enough for the water hardness in

the area?

Go to Question 5. Turn the rinse aid up to a

higher setting.

5 Using diagnostics, test the rinse

aid dispenser. Is it dispensing the

correct amount of rinse aid?

Replace dispenser.

6.2 Poor Dry Performance

Poor Dry Performance (Vented Single Product)

Complaint Answer

1 Customer complaining about

water on the oor after drying

Due to cold ambient conditions, the moist air from

the external vent may cause a mist on the oor, and in

extreme cold ambient conditions water can drip from

the external vent.

Gurgling Has the ap

2 Drying fan not operating There is a time lag of between 30-40 minutes to let the

water condense within the tub before drying starts.