25

Models 345, 346, 349, 355 Operating P rocedures

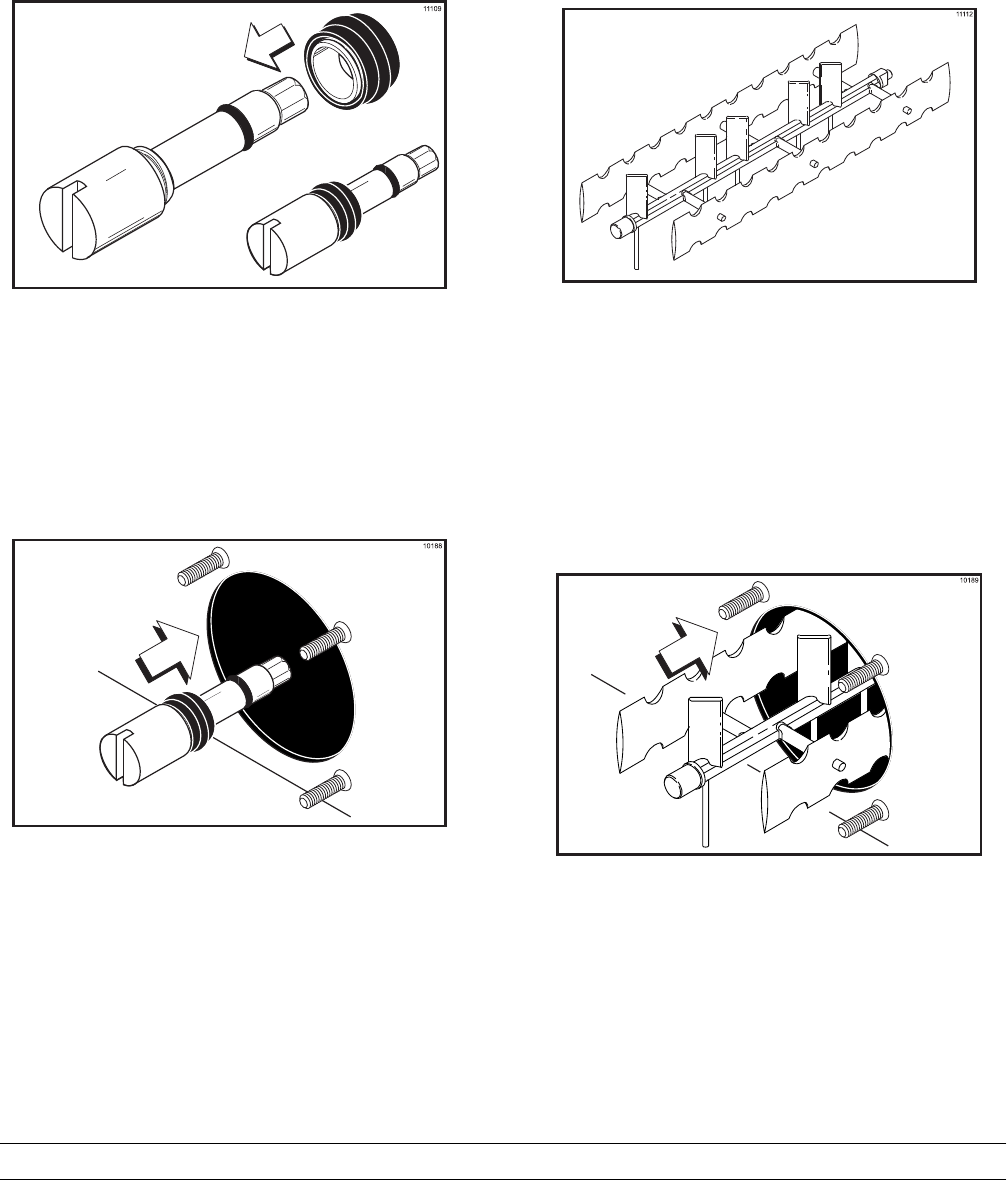

Note: The drive shaft bushing must be positioned in

the center of the drive shaft s eal.

Slide the seal and bushing ov er the shaft and groove

until it snaps into place. Fill the inside portion of the

seal with 1/4” more lubricant and evenly lubricate the

end of the seal that fits onto the rear shell bearing.

Figure 11

Insert the beater drive shaft into the freezing cylinder,

hex end first, and into the rear shell bearing until the

seal fits securely over therear shell bearing. Becertain

the drive shaft fits into the drive coupling without

binding. Remove any excess lubricant from t he seal.

Figure 12

Step 2

Install the beater assembly. First check the scraper

blades for any nic ks or s igns of wear. If any nicks are

present or if the blade is worn, r eplace both blades. If

the blades are in good condition, place the scraper

blades ov er the holding pins on the beater.

Note: Each hole on the scraper blade must fit

securely over eac h pin.

Figure 13

Align the flats on the end of the beater assembly with

the drive shaft. Make sure the beater assembly

locating pin is inposition inthelocating holeof thedrive

shaft. Turn the beater slightly to be certain that the

beater is properly seated. When in position, the beater

will be approximately 3/8” inside the front of the

freezing cylinder.

Important: Failure to properly seat the beater may

cause damage to the beater and the door.

Figure 14