4

Models 345, 346, 349, 355To the Instal ler

131122

Use only R404A refrigerant that conforms to

the AHRI standard 700 specification. The use of any

other refrigerant may expose users and operators to

unexpected safety hazards.

Refrigerant liquid sprayed onto the skin may

cause serious dam age to tissue. Keep eyes and skin

protected. If refrigerant burns should occur, flush

immediately with cold water. If burns are severe, apply

ice pac ks and contact a physician immediately.

Taylor reminds technicians to be cautious of

government laws regarding refrigerant recovery,

recycling, and reclaiming systems. If you have any

questions regarding these laws, please contact the

factory Service Department.

W ARNING: R404A refrigerant used in

conjunction with polyolester oils is extremely moisture

absorbent. When opening a refrigeration system, the

maximum time the system is open must not exceed 15

minutes. Cap all open tubing to prevent humid air or

water from being absorbed by the oil.

Syrup System Connections

1. Water pipe c onnections and fixtures directly

connected to a potable water supply shall be

sized, installed and maintained according to

federal, state and local l aws.

2. Hook up cold water supply to freezer to supply

water to the carbonator. A minimum o f 21 PSI

of water pressure is required at the low

pressure switch. The low pressure switch will

cause the entire freezer to shut down if the

water pressure drops below 7 PSI for longer

than one minute.

The water regulator should be set at 35 PSI.

When the power switch is turned on the water

pump will immediately activate to maintain water

pressure.

3. Electrical Hook-Up

a. One power cord.

b. Refer to the data label.

c. Be sure all control switches onthe front panel

are in the “OFF” position.

d. The freezer must be properly grounded.

4. A harness with three ny lobrade tubes feeds

through the base pan and exits the rear of the

freezer. (The Model 355 is equipped with four

tubes.)

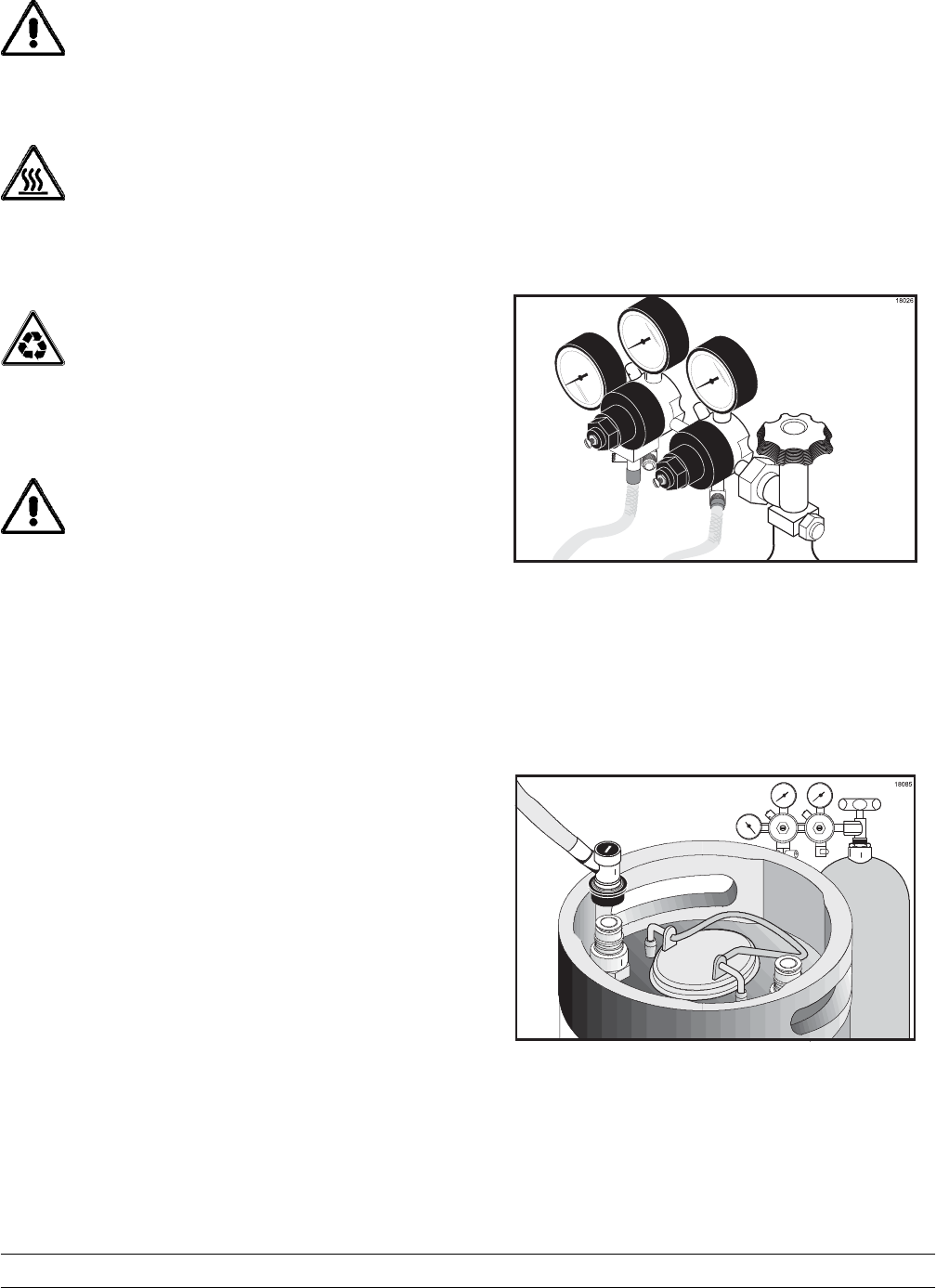

a. Connect the CO

2

line to the CO

2

regulator

that is closest to the CO

2

tank (primary

regulator). This line will supply CO

2

to the

freezer.

Figure 2

b. Connect the #1 line to the syrup tank for the

left side of the freezer as viewed from the

front of the machine. This line will supply

syrup to the left syrup sentry.

Note: For Bag-in-Box units (BIB), connect the #1 line

to the Bag-In-Box instead of the syrup tank.

Figure 3

c. Connect the #2 line to the syrup tank (or the

Bag-in-Box) for the right side of the freezer.

This line will supply syrup to the right syrup

sentry.