35

Models 345, 346, 349, 355 Operating P rocedures

Step 9

Replace the side panels and close the lighted display.

Install the hood in position on top of the freezer.

90 Day Closing Procedure

We recommend that the machine be completely

disassembled and cleaned at least every ninety days

using the following procedures.

ALWAYS FOLLOW LOCAL HEALTH CODES

To disassemble a freezer, the following items will be

needed:

S T wo cleaning pails

S Necessary brushes (provided with freezer)

S Cleaner

S Single s ervice towels

Draining Product From the

Freezing Cylinder

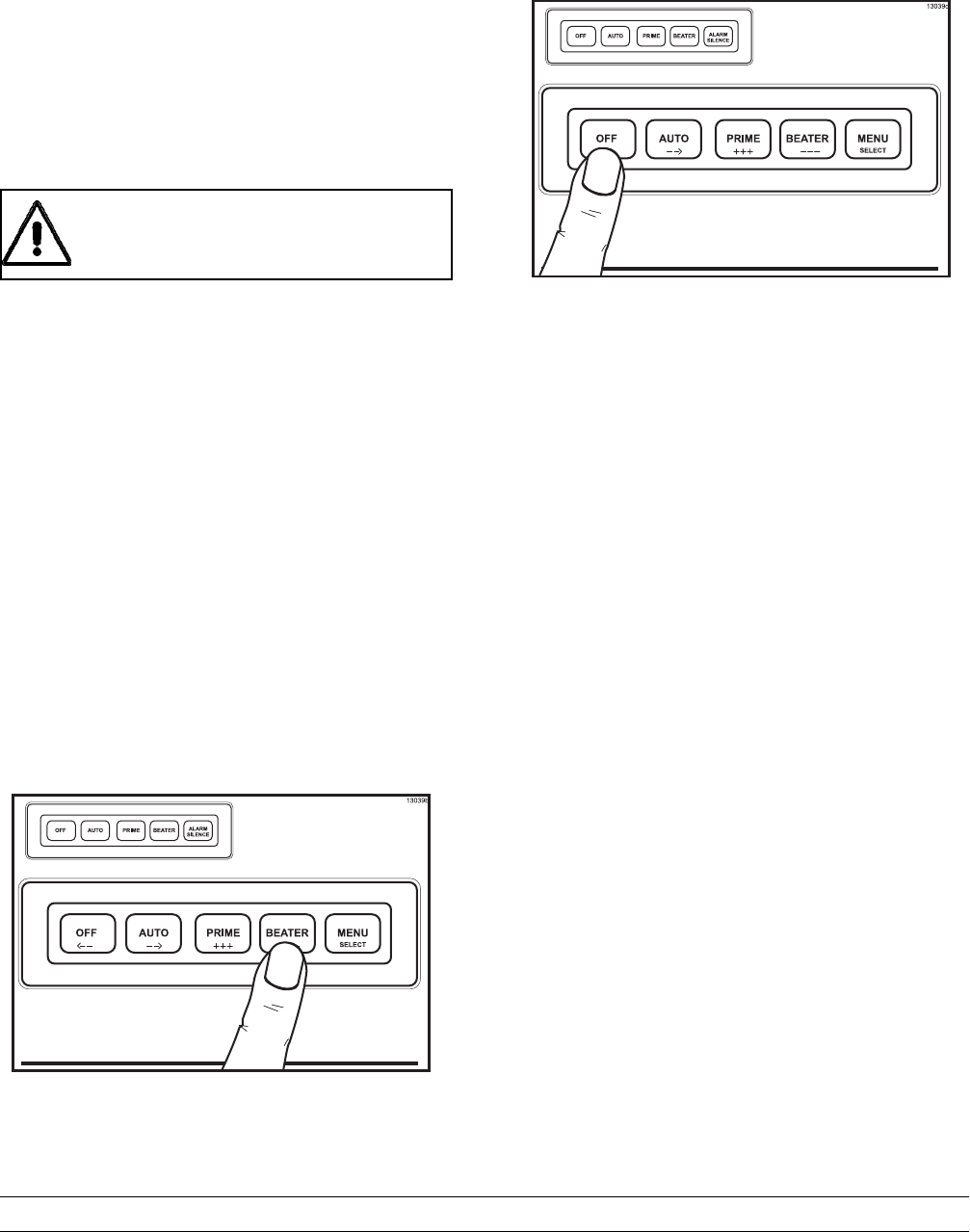

Step 1

Press the BEATER key. This will allow the beater to

operate and CO

2

pressure will be maintained to push

the product from the freezing cylinder. Open the draw

valve and drain the product from the machine until the

CO

2

begins to jet.

Figure 56

Step 2

When all the product has been drained from the m ix

hopper and the freezing cylinder, close the draw valve

and press the OFF key. Discard this pr oduct.

Figure 57

Repeat Steps 1 and 2 for the remaining freezing

cylinder(s).

Cleaning

Step 1

Open the lighted display door from the front of the

machine. Remove the hood and side panels to gain

access to the hoppers.

Step 2

Prepare two gallons (7.6 liters) of an approved clean-

ing solution (example: Kay-5

R). USE WARM WATER

AND FOLLOW THE MANUFACTURER’S SPECIFI-

CATIONS.

Important: Make sure the cleaner is completely

dissolved.

Step 3

Pour the solution into a clean, empty bucket. Place the

syrup line with old syrup connection into the bucket of

sanitizer.

Step 4

Press the PRIME key. This will cause the cleaning

solution to flow through the lines and into the mix

hopper.

Step 5

Remove the front drip tray. Place a mix pail beneath

the sampling valve located behind the front drip tray.

Slowly open the sampling valve and allow cleaner to

flow through this line and out into the pail. After

approximately 1/2 gallon of cleaner has been

dispensed, close the valve.