34

Models 345, 346, 349, 355Operating P rocedures

Allow the pr oduct to flow over the refractometer. T he

brix reading should register 13 to 14. A reading higher

than this would cause a darker, richer product. The

refrigeration system would have to runlonger tofreeze

this excess syrup. A reading lower than this could

cause a freeze-up in the freezing cylinder because of

the excess water.

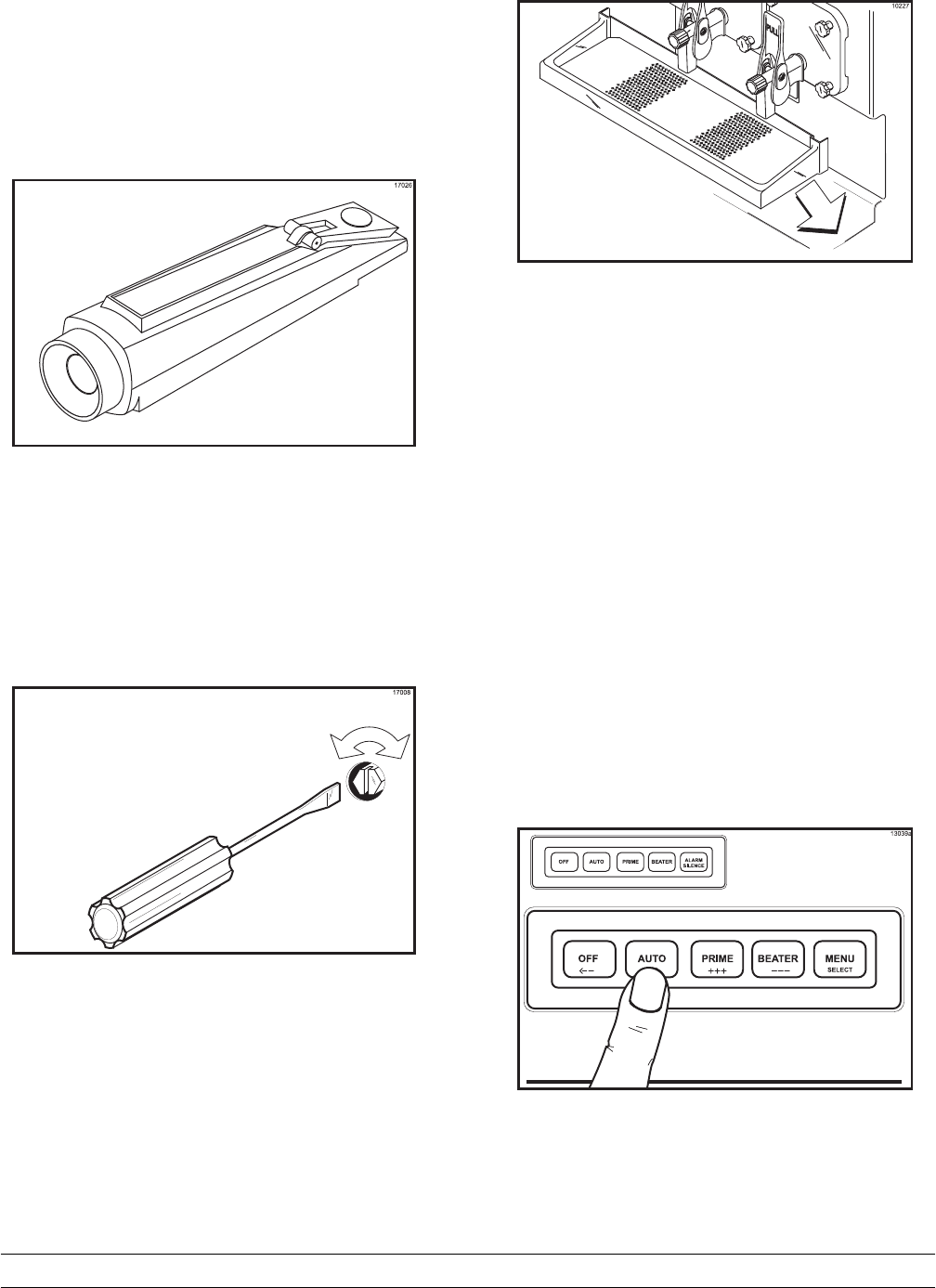

Figure 52

To adjust the brix, turn the adjustment screw located

in t he service panel. Clockwise adjustments increase

the amount of syrup to water, and counterclockwise

adjustments decrease the amount of syrup to water.

Adjust the screw in small increments and check the

brix again.

Figure 53

Repeat this step until a correct brix reading is

registered.

Step 5

Once the proper brix has been achieved, close the

sampling valve. Install the front drip tray andthesplash

shield on the front of the freezer.

Figure 54

Step 6

With a pail beneath the door spout, press the BEATER

key. Open the draw valve and drain the freezing

cylinder. Close the draw valve. After three minutes,

press the PRIME key. This will cause the product to

flow to the mix hopper.

Step 7

Hold a large cup under the pressure relief port exit of

the door, until the liquid level (not foam) reaches the

pressure relief port. Lower the prime plug. Press the

OFF key.

Note: A large amount of foam indicates that the prime

plug was raised too high.

Repeat Steps 1 through 7 for the remaining freezing

cylinder(s).

Step 8

To place the freezing cylinder in the AUTO mode,

press the AUTO key. When the unit cycles off, the

product will be at serving viscosity.

Figure 55

Repeat this step for the remaining freezing

cylinder(s).