Model 500/600

This reservoir holds the peanut oil, and is designed to hold

12 lb (5.4 kg) of product, with a “cold zone” for collection of crumbs

Provides the pressure seal for the frypot chamber

The deadweight style, pressure relief valve maintains a constant level of

operating steam pressure within the frypot; excess steam is vented

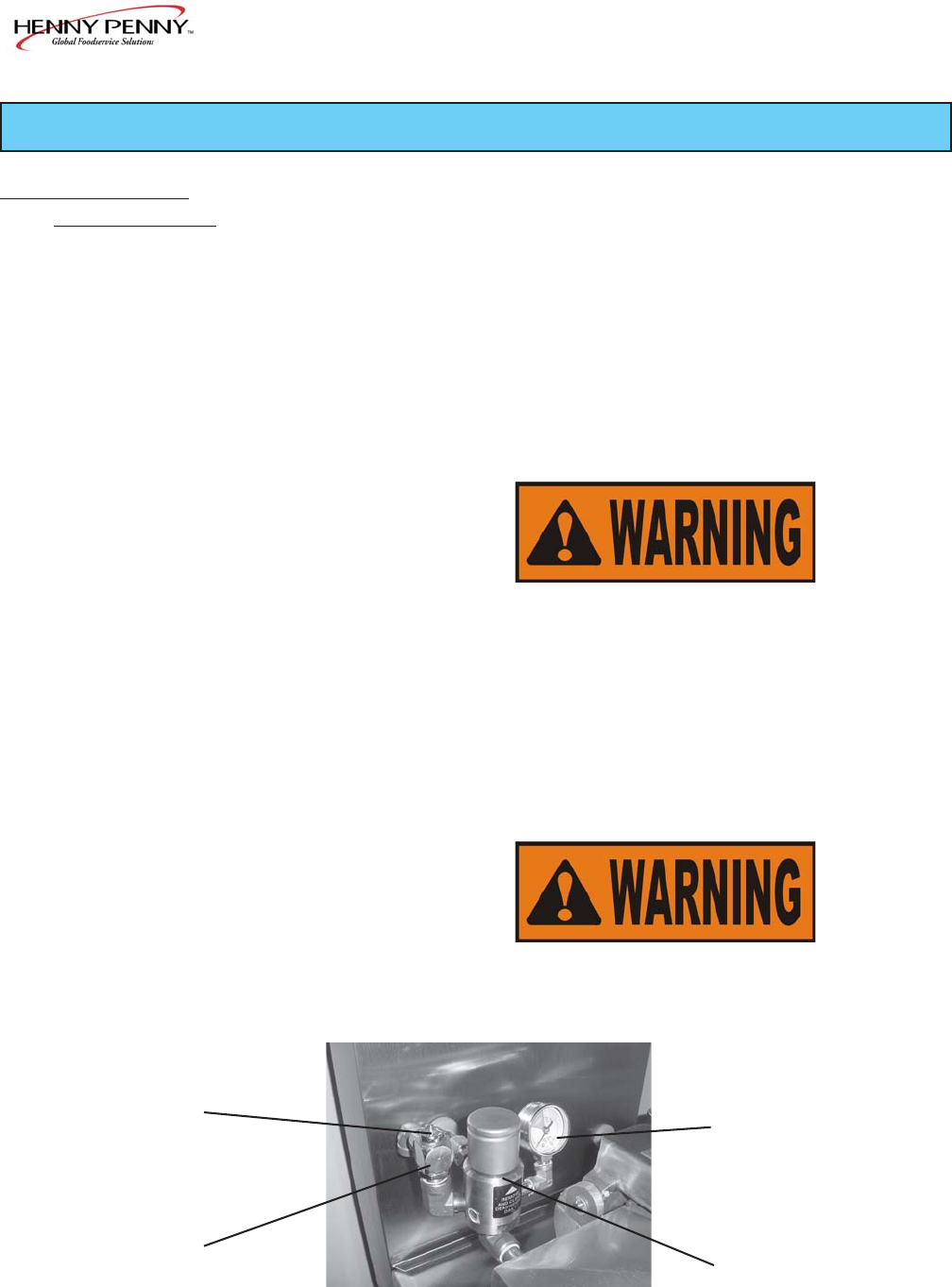

through the exhaust stack. (See Figure 3-1)

Failure to clean the deadweight assembly daily could result in

the fryer building too much pressure. Severe injuries and

burns could result.

An ASME approved, spring loaded valve, set at 14.5 psi; in the event

the deadweight valve becomes clogged, this safety valve releases

excess pressure, keeping the frypot chamber at 14.5 psi; if this occurs,

turn the COOK/PUMP switch OFF to release all pressure from the

frypot. (See Figure 3-1)

If safety relief valve activates, turn main power switch

to the OFF position. To avoid serious burns and injuries,

have fryer serviced before next use.

3-1. OPERATING

COMPONENTS

Frypot

Lid Gasket

Deadweight Assembly

Safety Relief Valve

SECTION 3. OPERATION

803 3-1

Saftey Relief

Valve Ring

Saftey Relief V alve

Deadweight Valve

Figure 3-1

Pressure Gauge