SGB Batch Blender with Mitsubishi Controller Page 17 of 118

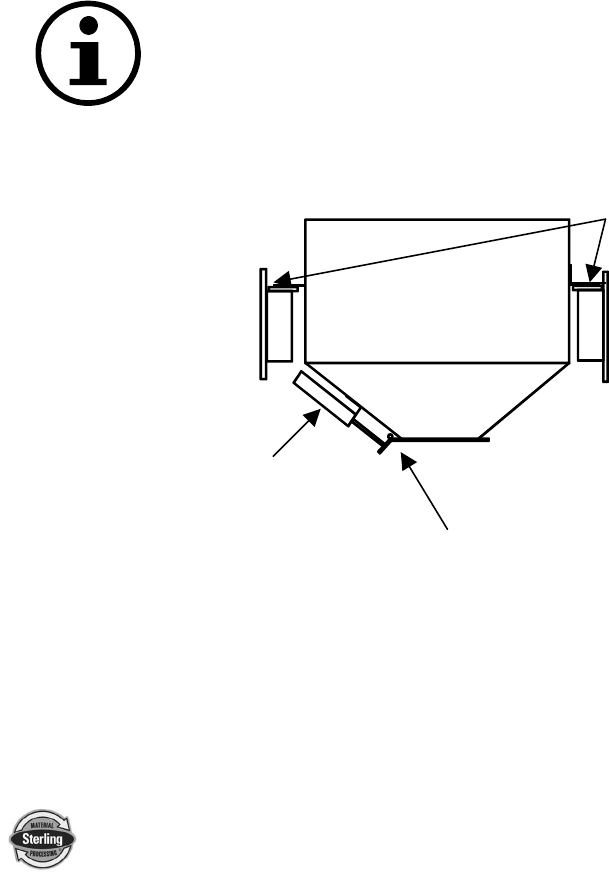

1-11-3 Weigh Hopper

The weigh hopper on the SGB blender is used to weigh each batch of

material, and includes an air-operated discharge valve. After the batch

is weighed and the level sensor in the lower mix section is uncovered,

the valve will open and discharge the batch into the mixer with the

existing blended material. The discharge valve is also provided with a

quick disconnect so the weigh hopper can be removed for cleaning.

On an SGB blender, the weigh hopper rests on each side on a

precision cantilever load cell. To remove the weigh hopper, lift the

hopper from the bottom, hold the discharge valve closed, and slide it

out once clear of the locating tab on the bracket above the load cell.

Once the hopper has been cleaned, reposition it onto the load cell

brackets, using care not to damage the load cells. Position the hopper

as close to the center position between the load cells as possible.

Important! Use care when replacing the weigh hopper, since the load cells are

delicate weighing instruments and can be easily damaged. Do not

use force to push in the weigh hopper. If it is positioned properly,

it will slide in very easily.

Load cells, if damaged, will have to be sent back to the

manufacturer for testing and evaluation.

DISCHARGE VALVE

LOAD CELL

LOAD CELL

WEIGH HOPPER

LOCATING TABS

A

IR CYLINDER