SGB Batch Blender with Mitsubishi Controller Page 39 of 118

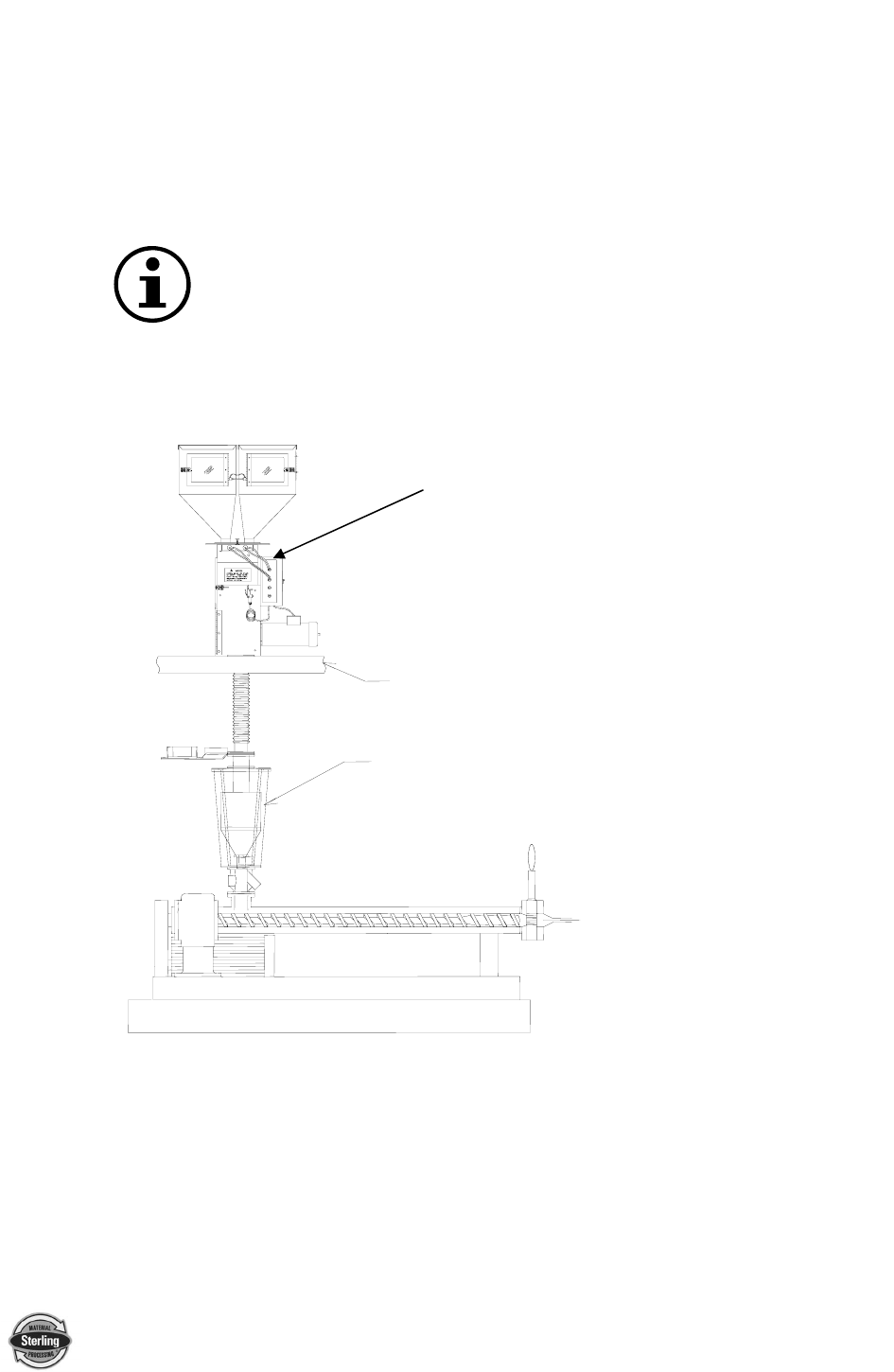

4-2-1-2 Mezzanine Mount

In a mezzanine mount application, review the following items

before installation begins. First, verify the SGB mounting

locations match the mezzanine supports. Verify that the

mezzanine is capable of supporting the blender with a full load

of material and vacuum loading equipment installed.

Important! While in operation, the SGB applies horizontal and vertical

pressures to the mounting flange. If there is a question as

to the mechanical stability of a mounting flange, contact

Sterling’s Mechanical Engineering department.

Ensure that the gravity feed tube is installed in a vertical

position, so that the materials will gravity flow to the extruder

hopper. Use aluminum tubing or smooth wall flex hose.

If possible, use rigid tubing. Some flex hose will tend to sag and

generate static that could cause de-mixing between the blender

and the extruder.

Make sure that adequate space is around the blender (36”

recommended) to allow proper cleaning, servicing, etc.

MEZZANINE (SUPPLIED BY

CUSTOMER)

OFC WITH RE-LOAD VALVE

(PURCHASED SEPARATELY)

GRAVIMETRIC BATCH BLENDER