24

7-INSTALLATION AND SETUP (continued)

7.12 Box Size Capacity of Case Sealer

At its factory setting, the case sealer handles box

sizes up to 620mm [24.5 inch] maximum height

(See Specif cations Section). If larger capacity is

needed, the machine can be adjusted to accom-

modate boxes up to 725mm [28.5 inch] high.

Refer to "Special Setup Procedure – Box and

Machine Bed Height Range."

Note – Adjusting machine to accommodate 725mm

[28.5 inch] high boxes also increases minimum box

size to 170mm [6.8 inch] - See Parts list.

7.14 Initial Start-Up of Case Sealer

After completing the "Installation and Setup"

procedure, continue through "Operation" for tape

loading and start-up to be sure case sealer is

properly adjusted to run boxes.

7.13 Electrical Connections and Controls

The electrical control box and "On/Off" switch are

located on the lower left side of the machine frame

(Figure 7-13). If desired, for operator convenience,

the "On/Off" switch can be relocated to the right

side of the machine frame. The receptacle providing

this service shall be properly grounded. Before

the power cord is plugged in, make sure that all

packaging materials and tools are removed from the

machine.

Do not plug electrical cord into outlet until ready

to run machine.

• To reduce the risk associated with

impact hazards:

− Always use appropriate supporting

means when working under the upper

drive assembly

• To reduce the risk associated with

mechanical and electrical hazards:

− Allow only properly trained and

qualifi ed personnel to operate and/or

service this equipment

WARNING

• To reduce the risk associated

with hazardous voltage:

− Position electrical cord away from foot

and/or vehicle traffi c

WARNING

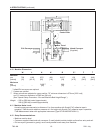

7.11 Bumper Supports (Upper Drive Assembly)

With the Safety Guard removed (see Installation and

Setup / Figure 7-7):

• Raise and lock the upper drive assembly in the

raised position. See "Operation – Mechanical Latch."

• Turn off air supply and electric power.

• Remove the Column Bumper and set screw parts

package from the carton.

• Using set screws provided, install Column

Bumper (the recommended position is

shown Below).

• Re-install Safety Guard.

* Note - Important - Some bumper positions may:

1) Allow upper and lower taping heads to come into

contact with each other.

2) Create added stress to the bumper.

3) Cause a malfunction of the machine.

These events can potentially cause damage to the

machine. For more information on bumper settings,

contact your 3M service representative.

Do Not

Use

Bottom

Holes

700r-NA

2011 July