MODIFY CONTROLLER IDENTIFICATION IF NECES-

SARY — The controller identification screen is used to change

the PSIO module address. Change this address for each chiller

if there is more than one chiller at the jobsite. Write the new

address on the PSIO module for future reference.

Change the LID address if there is more than one chiller

on the jobsite. Access the LID configuration screen to view

or modify this address.

INPUT EQUIPMENT SERVICE PARAMETERS IF NEC-

ESSARY — The Equipment Service table has three service

tables: Service1, Service2, and Service3.

Configure SERVICE1 Table — Access Service1 table to

modify/view the following to jobsite parameters:

Chilled Medium Water or Brine?

Brine Refrigerant Trippoint Usually 3° F (1.7° C) below

design refrigerant temperature

Surge Limiting or Hot Gas

Bypass (HGBP) Option

Is HGBP installed?

Minimum Load Points

(T1/P1)

Per job data —

See Modify Load Points section

Maximum Load Points

(T2/P2)

Per job data —

See Modify Load Points section

Amps Correction Factor See Table 6

Motor Rated Load Amps Per job data

Motor Rated Line Voltage Per job data

Motor Rated Line kW Per job data

(if kW meter installed)

Line Frequency 50 or 60 Hz

Compressor Starter Type Reduced voltage or full?

NOTE:Other valuesareleftat thedefaultvalues.Thesemay bechanged

bythe operatoras required.Service2 andService3 tablescanbe modi-

fied by the owner/operator as required.

Modify Minimum and Maximum Load Points (⌬T1/P1;

⌬ T2/P2) If Necessary —These pairs of chiller load points,

located on the Service1 table, determine when to limit guide

vane travel or to open the hot gas bypass valve when surge

prevention is needed. These points should be set based on

individual chiller operating conditions.

If, after configuring a value for these points, surge pre-

vention is operating too soon or too late for conditions, these

parameters should be changed by the operator.

Example of configuration: Chiller operating parameters

Refrigerant used: HCFC-22

Estimated Minimum Load Conditions:

44 F (6.7 C) LCW

45.5 F (7.5 C) ECW

43 F (6.1 C) Suction Temperature

70 F (21.1 C) Condensing Temperature

Estimated Maximum Load Conditions:

44 F (6.7 C) LCW

54 F (12.2 C) ECW

42 F (5.6 C) Suction Temperature

98 F (36.7 C) Condensing Temperature

Calculate Maximum Load — To calculate maximum load

points, use design load condition data. If the chiller full load

cooler temperature difference is more than 15° F (8.3 C),

estimate the refrigerant suction and condensing tempera-

tures at this difference. Use the proper saturated pressure and

temperature for the particular refrigerant used.

Suction Temperature:

42 F (5.6 C) = 71.5 psig (521 kPa) saturated

refrigerant pressure (HCFC-22)

Condensing Temperature:

98 F (36.7 C) = 190 psig (1310 kPa) saturated

refrigerant pressure (HCFC-22)

Maximum Load ⌬T2:

54 – 44 = 10° F (12.2 – 6.7 = 5.5° C)

Maximum Load ⌬P2:

190 – 71.5 = 118.5 psid (1310 – 521 = 789 kPad)

To avoid unnecessary surge prevention, add about 10 psid

(70 kPad) to ⌬P2 from these conditions:

⌬T2 = 10° F (5.5° C)

⌬P2 = 130 psid (900 kPad)

Calculate Minimum Load — To calculate minimum load con-

ditions, estimate the temperature difference that the cooler

will have at 10% load, then estimate what the suction and

condensing temperatures will be at this point. Use the proper

saturated pressure and temperature for the particular refrig-

erant used.

Suction Temperature:

43 F (6.1 C) = 73 psig (503 kPa) saturated

refrigerant pressure (HCFC-22)

Condensing Temperature:

70 F (21.1 C) = 121 psig (834 kPa) saturated

refrigerant pressure (HCFC-22)

Minimum Load ⌬T1:

45.5 – 44 = 1.5° F (7.5 – 6.7 = 0.8° C)

Minimum Load ⌬P1:

121 – 73 = 45 psid (834 – 503 = 331 kPad)

Again, to avoid unnecessary surge prevention, add 10 psid

(70 kPad) at ⌬P1 from these conditions:

⌬T1 = 1.5 F (0.8 C)

⌬P1 = 60 psid (410 kPad)

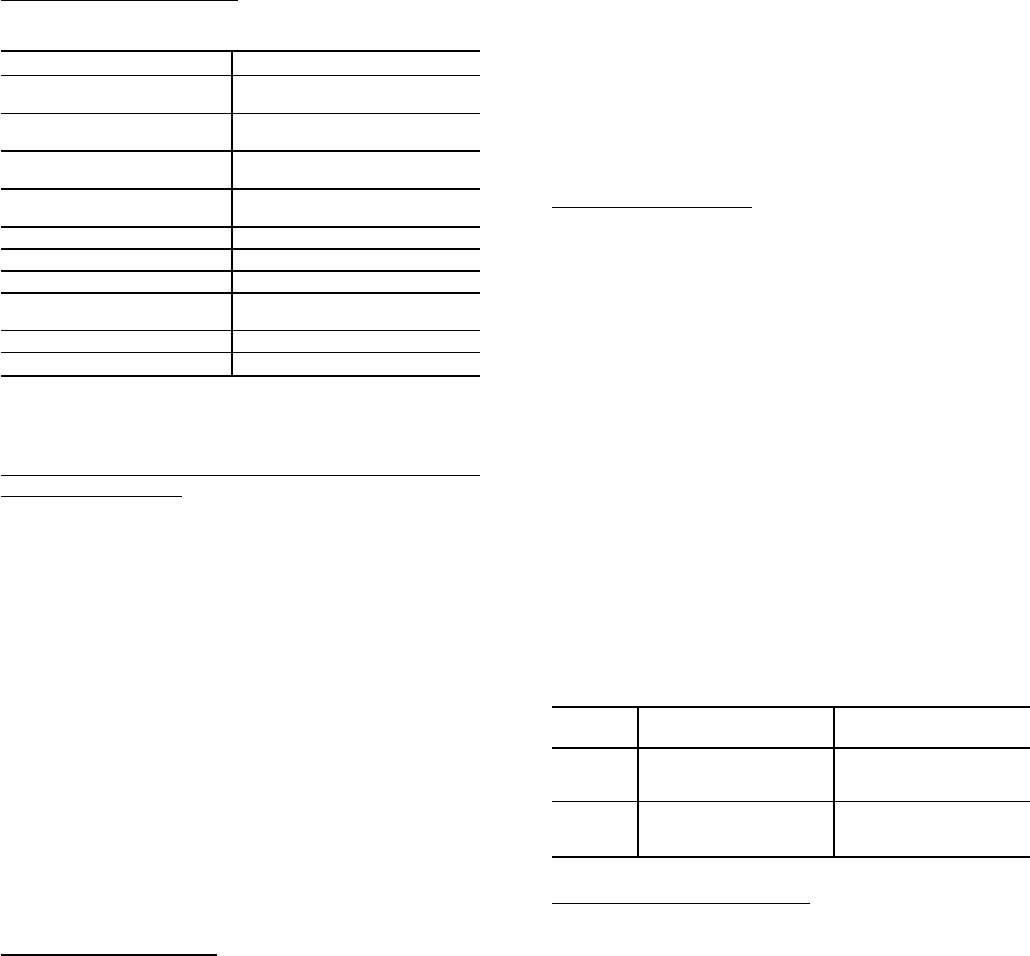

If surge prevention occurs too soon or too late:

LOAD

SURGE PREVENTION SURGE PREVENTION

OCCURS TOO SOON OCCURS TOO LATE

At low

loads

(Ͻ50%)

Increase P1 by

10 psid (70 kPad)

Decrease P1 by

10 psid (70 kPad)

At high

loads

(Ͼ50%)

Increase P2 by

10 psid (70 kPad)

Decrease P2 by

10 psid (70 kPad)

Modify Amp Correction Factors — To modify the amp cor-

rection factor, use the values listed in Table 6. Enter the

appropriate amp correction factor in the Service1 table of

Equipment Service.

51