HCFC-22 and HFC-134a should not be mixed with

air or oxygen and pressurized for leak testing. In gen-

eral, neither refrigerant should not be allowed to be pre-

sent with high concentrations of air or oxygen above

atmospheric pressures, as the mixture can undergo

combustion.

REFRIGERANT TRACER — Use an environmentally

acceptable refrigerant as a tracer for leak test procedures.

TO PRESSURIZE WITH DRY NITROGEN — Another

method of leak testing is to pressurize with nitrogen only

and use a soap bubble solution or an ultrasonic leak detector

to determine if leaks are present. This should only be done

if all refrigerant has been evacuated from the vessel.

1. Connect a copper tube from the pressure regulator on the

cylinder to the refrigerant charging valve. Never apply

full cylinder pressure to the pressurizing line. Follow the

listed sequence.

2. Open the charging valve fully.

3. Slowly open the cylinder regulating valve.

4. Observe the pressure gage on the chiller and close the

regulating valve when the pressure reaches test level. Do

not exceed 140 psig (965 kPa).

5. Close the charging valve on the chiller. Remove the cop-

per tube if no longer required.

Repair the Leak, Retest, and Apply Standing

Vacuum Test —

After pressurizing the chiller, test for

leaks with an electronic, halide leak detector, soap bubble

solution, or an ultrasonic leak detector. Bring the chiller back

to atmospheric pressure, repair any leaks found, and retest.

After retesting and finding no leaks, apply a standing vacuum

test, and then dehydrate the chiller. Refer to the Standing

Vacuum Test and Chiller Dehydration in the Before Initial

Start-Up section, pages 43 and 47.

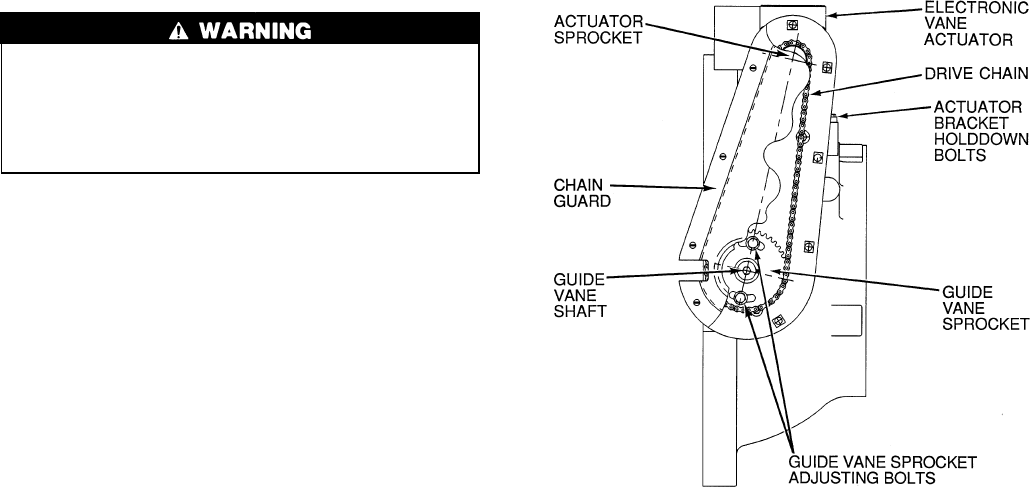

Checking Guide Vane Linkage — When the chiller

is off, the guide vanes are closed and the actuator mecha-

nism is in the position shown in Fig. 36. If slack develops in

the drive chain, backlash can be eliminated as follows:

1. With the machine shut down and the actuator fully closed,

remove the chain guard and loosen the actuator bracket

holddown bolts.

2. Loosen guide vane sprocket adjusting bolts.

3. Pry bracket upwards to remove slack, then retighten the

bracket holddown bolts.

4. Retighten the guide vane sprocket adjusting bolts. Make

sure that the guide vane shaft is rotated fully in the clock-

wise direction in order for it to be fully closed.

CHECKING THEAUXILIARY SWITCH ON GUIDE VANE

ACTUATOR — The auxiliary switch used to activate the oil

reclaim system solenoids should move to the OPEN posi-

tion when the actuator is 70 degrees open. (At this point the

guide vanes should be 30 degrees open.)

Trim Refrigerant Charge — If it becomes necessary

to adjust the refrigerant charge to obtain optimum chiller per-

formance, operate the chiller at design load and then add or

remove refrigerant slowly until the difference between leav-

ing chilled water temperature and the cooler refrigerant tem-

perature reaches design conditions or becomes a minimum.

Do not overcharge.

Refrigerant may be added either through the storage tank

or directly into the chiller as described in the Charge

Refrigerant into Chiller section.

To remove any excess refrigerant, follow the procedure in

Transfer Refrigerant from Chiller to Storage Tank section,

Steps 1a and b, page 60.

WEEKLY MAINTENANCE

Check the Lubrication System —

Mark the oil level

on the reservoir sight glass, and observe the level each week

while the chiller is shut down.

If the level goes below the lower sight glass, the oil

reclaim system will need to be checked for proper operation.

If additional oil is required, add it through the oil drain

charging valve (Fig. 2A or Fig. 2B). A pump is required for

adding oil against refrigerant pressure. The oil charge is

approximately 8 gallons (30 L). The added oil must meet

Carrier specifications for the 19XL. Refer to Changing Oil

Filter and Oil Changes sections on page 63. Any additional

oil that is added should be logged by noting the amount and

date. Any oil that is added due to oil loss that is not related

to service will eventually return to the sump. It must be

removed when the level is high.

A 1200-watt oil heater is controlled by the PIC to main-

tain oil temperature (see the Controls section) when the

compressor is off. The LID Status02 table displays whether

the heater is energized or not. If the PIC shows that the heater

is energized, but the sump is not heating up, the power to the

oil heater may be off or the oil level may be too low. Check

the oil level, the oil heater contactor voltage, and oil heater

resistance.

The PIC will not permit compressor start-up if the oil

temperature is too low. The control will continue with start-up

only after the temperature is within limits.

Fig. 36 — Guide Vane Actuator Linkage

62