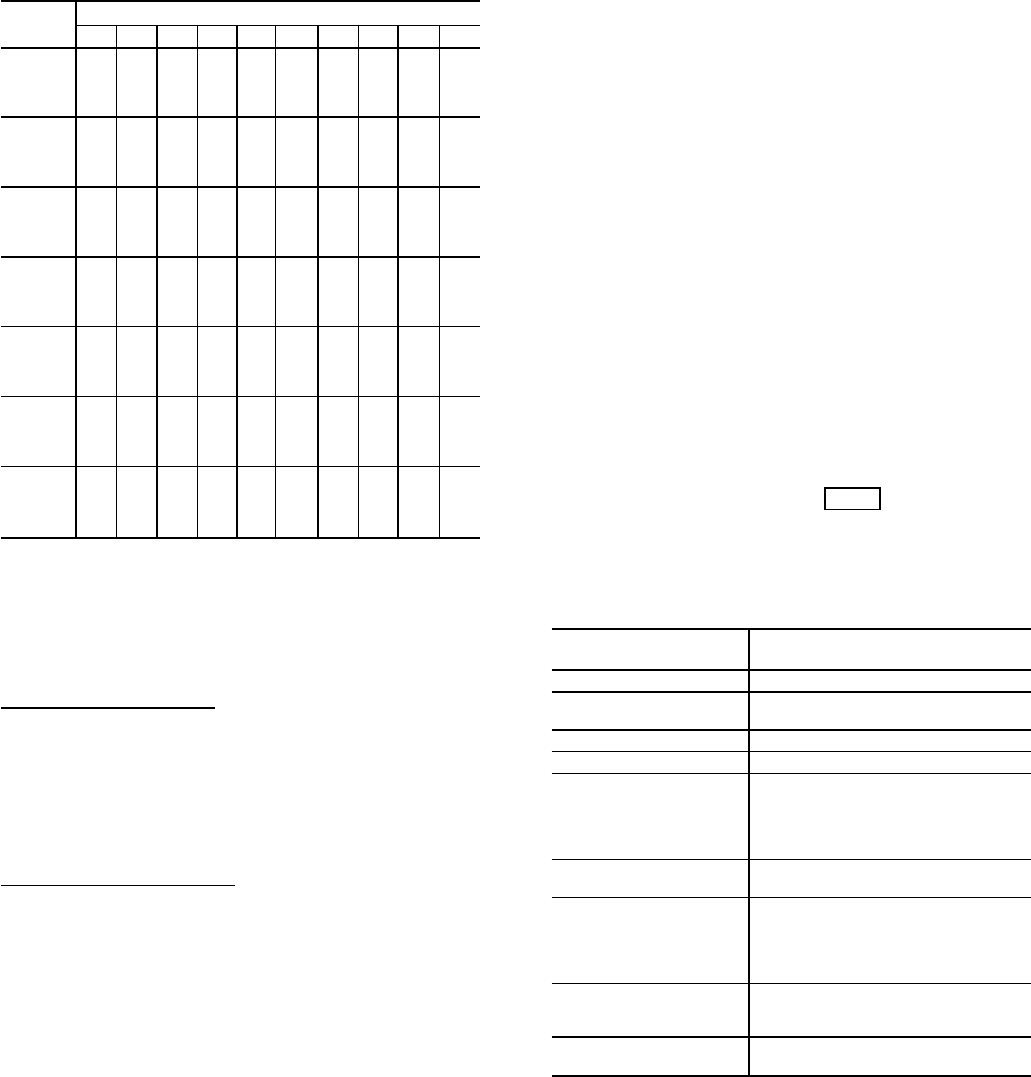

Table 6 — Amps Correction Factors

for 19XL Motors

VOLT/

Hz

MOTOR CODE

CB CC CD CE CL CM CN CP CQ CR

200/60 4536323222

208/60 5558424222

220/60 3422231111

230/60 5644352222

240/60 5644382222

360/60 4242221111

380/60 7464453222

400/60 7584453234

440/60 3322111134

460/60 5432222256

480/60 7543333378

550/60 4232123222

575/60 4442234333

600/60 8564346544

3300/60 4441233322

2400/60 4433232233

4160/60 4433232233

220/50 3122232111

230/50 4223243211

240/50 5354353322

320/50 2222111133

346/50 4433321234

360/50 5544422288

380/50 5233324222

400/50 6445436433

415/50 8556547544

3000/50 3223231212

3300/50 4333342212

MODIFY EQUIPMENT CONFIGURATION IF NECES-

SARY — The Equipment Configuration table has tables to

select and view or modify. Carrier’s certified drawings will

have the configuration values required for the jobsite. Modify

these tables only if requested.

Config Table Modifications — Change the values in this table

per job data. See certified drawings for values. Modifica-

tions include:

• chilled water reset

• entering chilled water control (Enable/Disable)

• 4-20 mA demand limit

• auto. restart option (Enable/Disable)

• remote contact option (Enable/Disable)

Owner-Modified CCN Tables— The following tables are de-

scribed for reference only.

Occdef Table Modifications — The Occdef tables contain

the Local and CCN time schedules, which can be modified

here, or in the Schedule screen as described previously.

Holidef Table Modifications — The Holidef tables configure

the days of the year that holidays are in effect. See the holi-

day paragraphs in the Controls section for more

details.

Brodefs Table Modifications — The Brodefs table defines

the outside-air temperature sensor and humidity sensor if one

is to be installed. It will define the start and end of day-

light savings time. Enter the dates for the start and end of

daylight savings if required for the location. Brodefs also

will activate the Broadcast function which enables the holi-

day periods that are defined on the LID.

Other Tables — The Alarmdef, Cons-def, and Runt-def con-

tain tables for use with a CCN system. See the applicable

CCN manual for more information on these tables.

These tables can only be defined through a CCN Building

Supervisor.

CHECK VOLTAGE SUPPLY— Access the Status 01 screen

and read the actual line voltage. This reading should be equal

to the incoming power to the starter. Use a voltmeter to check

incoming power at the starter power leads. If the readings

are not equal, an adjustment can be made to the 24-v input

to the SMM at the potentiometer located in the low-voltage

section to equalize the two readings.

PERFORMAN AUTOMATED CONTROLTEST — Check

the safety controls status by performing an automated con-

trols test. Access the Control Test table and select the

Automated Tests function (Table 8).

The Automated Control Test will check all outputs and

inputs for function. It will also set the refrigerant type. The

compressor must be in the OFF mode in order to operate the

controls test and the 24-v input to the SMM must be in range

(per line voltage percent on Status01 table). The OFF mode

is caused by pressing the STOP pushbutton on the LID. Each

test will ask the operator to confirm that the operation is oc-

curring, and whether or not to continue. If an error occurs,

the operator has the choice to try to address the problem as

the test is being done, or to note the problem and proceed to

the next test.

NOTE: If during the Control Test the guide vanes do not

open, check to see that the low pressure alarm is not active.

(This will cause the guide vanes to close).

NOTE: The oil pump test will not energize the oil pump if

cooler pressure is below –5 psig (–35 kPa).

When the test is finished, or the EXIT

softkey is pressed,

the test will be stopped and the Control Test menu will be

displayed. If a specific automated test procedure is not

completed, access the particular control test to test the func-

tion when ready. The Control Test menu is described as

follows:

Automated Tests As described above, a complete

control test.

PSIO Thermistors Check of all PSIO thermistors only.

Options Thermistors Check of all options boards

thermistors.

Transducers Check of all transducers.

Guide Vane Actuator Check of the guide vane operation.

Pumps Check operation of pump outputs,

either all pumps can be activated,

or individual pumps. The test will

also test the associated input such

as flow or pressure.

Discrete Outputs Activation of all on/off outputs or

individually.

Pumpdown/Lockout Pumpdown prevents the low refrig-

erant alarm during evacuation so

refrigerant can be removed from

the unit, locks the compressor off,

and starts the water pumps.

Terminate Lockout To charge refrigerant and enable

the chiller to run after pumpdown

lockout.

Refrigerant Type* Sets type of refrigerant used:

HCFC-22 or HFC-134a.

*Make sure toAttach to Local Device after changing refrigerant type.

Refer to Selecting Refrigerant Type section on page 50.

Check Optional Pumpout System Controls and

Compressor —

Controls include an on/off switch, a 3-amp

fuse, the compressor overloads, an internal thermostat, a com-

pressor contactor, and a refrigerant high pressure cutout. The

high pressure cutout is factory set to open at 220 ± 5 psig

(1250 ± 34 kPa), and automatically reset at 185 + 0,

−7 psig (1280 +0,–48 kPa) with HCFC-22. HFC-134a units

open at 161 psig (1110 kPa) and reset at 130 psig (896 kPa).

Check that the water-cooled condenser has been connected.

52