Water Treatment — Untreated or improperly treated wa-

ter may result in corrosion, scaling, erosion, or algae. The

services of a qualified water treatment specialist should be

obtained to develop and monitor a treatment program.

Water must be within design flowlimits, clean,and treated

to ensure proper chiller performance and reduce the

potential of tubing damage due to corrosion, scaling, ero-

sion, and algae. Carrier assumes no responsibility for

chiller damage resulting from untreated or improperly

treated water.

Inspect the Starting Equipment — Before work-

ing on any starter, shut off the chiller, and open all discon-

nects supplying power to the starter.

The disconnect on the starter front panel does not de-

energize all internal circuits. Open all internal and re-

mote disconnects before servicing the starter.

Never open isolating knife switches while equipment is

operating. Electrical arcing can cause serious injury.

Inspect starter contact surfaces for wear or pitting

on mechanical-type starters. Do not sandpaper or file silver-

plated contacts. Follow the starter manufacturer’s instruc-

tions for contact replacement, lubrication, spare parts order-

ing, and other maintenance requirements.

Periodically vacuum or blow off accumulated debris on

the internal parts with a high-velocity, low-pressure blower.

Power connections on newly installed starters may relax

and loosen after a month of operation. Turn power off and

retighten. Recheck annually thereafter.

Loose power connections can cause voltage spikes, over-

heating, malfunctioning, or failures.

Check Pressure Transducers — Once a year, the

pressure transducers should be checked against a pressure

gage reading. Check all three transducers: oil pressure, con-

denser pressure, cooler pressure.

Note the evaporator and condenser pressure readings

on the Status01 table on the LID. Attach an accurate set of

refrigeration gages to the cooler and condenser Schrader

fittings. Compare the two readings. If there is a difference in

readings, the transducer can be calibrated, as described in

the Troubleshooting Guide section.

Optional Pumpout System Maintenance —

For compressor maintenance details, refer to the 06D, 07D

Installation, Start-Up, and Service Instructions.

OPTIONAL PUMPOUT COMPRESSOR OIL CHARGE —

The pumpout compressor uses oil with the same specifi-

cations as the centrifugal compressor oil. For more details

on oil selection, see Oil Specification section, page 63.

The total oil charge, 4.5 pints (2.6 L), consists of

3.5 pints (2.0 L) for the compressor and one additional pint

(0.6 L) for the oil separator.

Oil should be visible in one of the compressor sight glasses

both during operation and at shutdown. Always check the

oil level before operating the compressor. Before adding or

changing oil, relieve the refrigerant pressure as follows:

1. Attach a pressure gage to the gage port of either com-

pressor service valve (Fig. 35).

2. Close the suction service valve and open the discharge

line to the storage tank or the chiller.

3. Operate the compressor until the crankcase pressure drops

to 2 psig (13 kPa).

4. Stop the compressor and isolate the system by closing

the discharge service valve.

5. Slowly remove the oil return line connection (Fig. 35).

Add oil as required.

6. Replace the connection and reopen the compressor serv-

ice valves.

OPTIONAL PUMPOUT SAFETY CONTROL SETTINGS

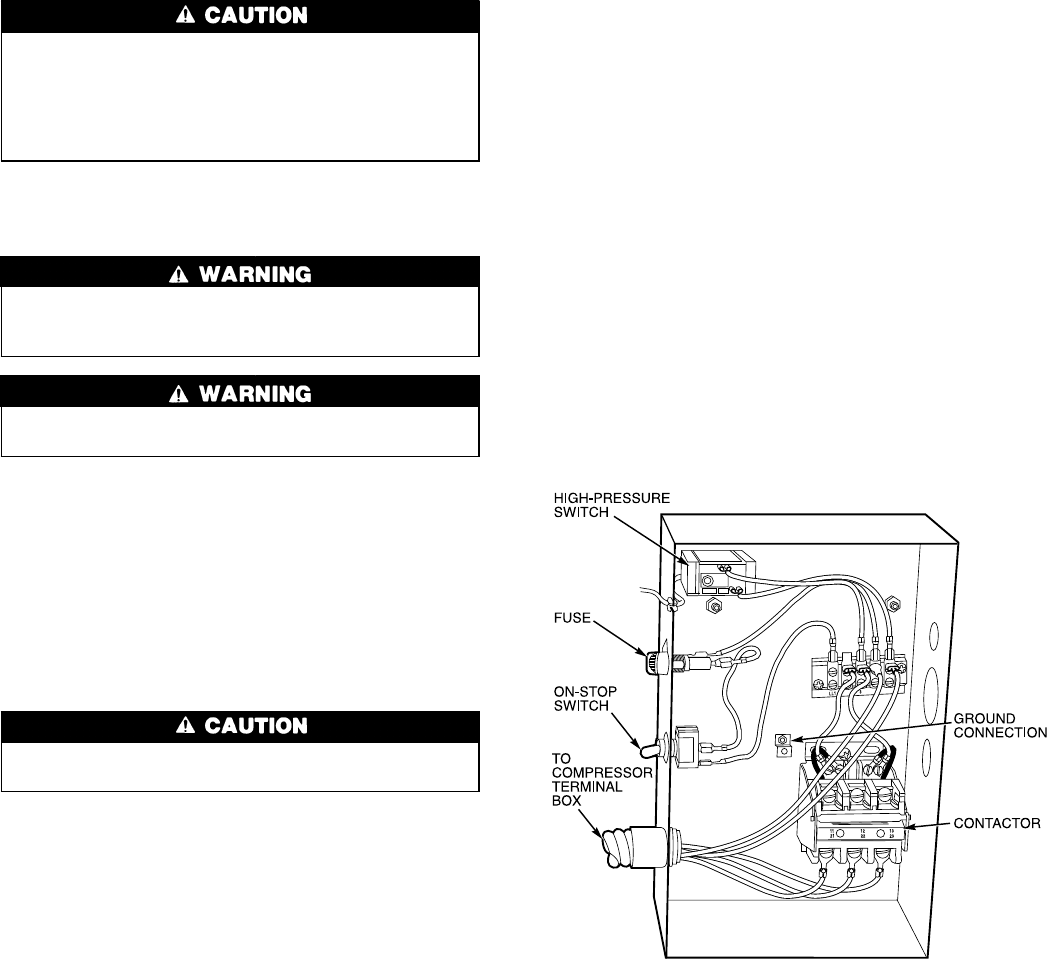

(Fig. 38) — The optional pumpout system high-pressure switch

should open at 220 ± 5 psig (1517 ± 34 kPa) and should

reset automatically on pressure drop to 190 psig (1310 kPa)

for HCFC-22 chillers. For chillers using HFC-134a, the

switch opens at 161 psig (1110 kPa) and closes at 130 psig

(896 kPa). Check the switch setting by operating the

pumpout compressor and slowly throttling the pumpout

condenser water.

Ordering Replacement Chiller Parts — When

ordering Carrier specified parts, the following information

must accompany an order:

• chiller model number and serial number

• name, quantity, and part number of the part required

• delivery address and method of shipment.

Fig. 38 — Optional Pumpout System

Controls

65