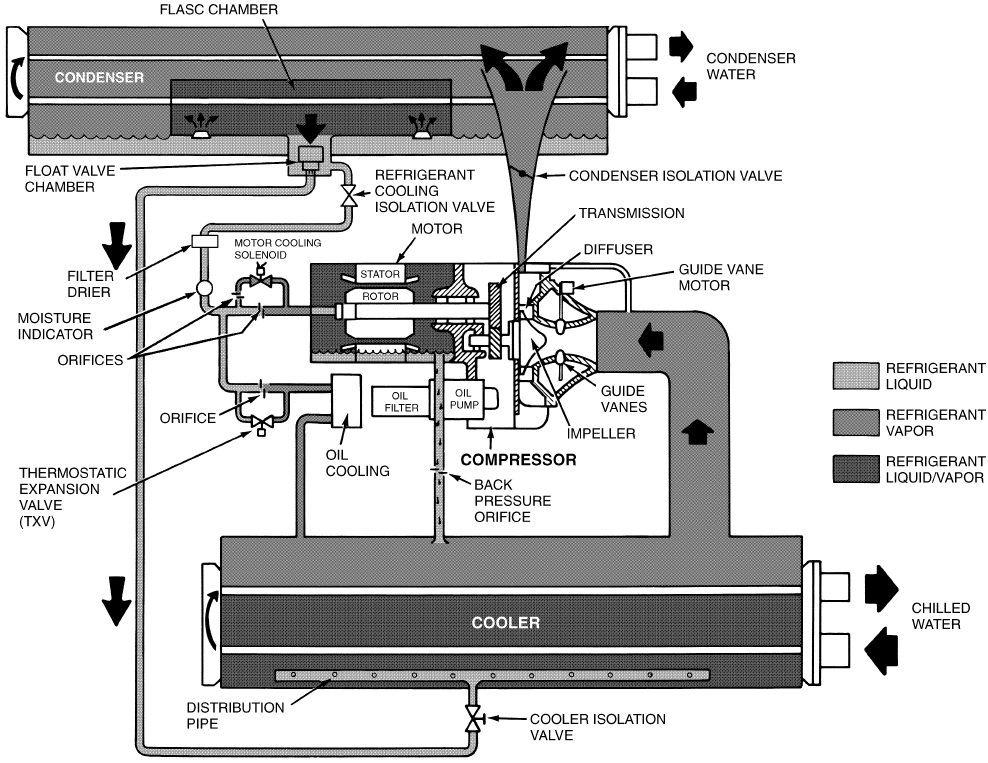

Refrigerant that flows to the oil cooling system is reg-

ulated by a thermostatic expansion valve. There is always

a minimum flow bypassing the TXV, which flows through

an orifice. The TXV valve regulates flow into the oil/

refrigerant plate and frame-type heat exchanger. The bulb

for the expansion valve controls oil temperature to the bear-

ings. The refrigerant leaving the heat exchanger then returns

to the cooler.

LUBRICATION CYCLE

Summary —

The oil pump, oil filter, and oil cooler make

up a package located partially in the transmission casting of

the compressor-motor assembly. The oil is pumped into a

filter assembly to remove foreign particles, and is then forced

into an oil cooler heat exchanger where the oil is cooled to

proper operational temperatures. After the oil cooler, part of

the flow is directed to the gears and the high speed shaft

bearings; the remaining flow is directed to the motor shaft

bearings. Oil drains into the transmission oil sump to com-

plete the cycle (Fig. 4).

Details — Oil is charged into the lubrication system through

a hand valve. Two sight glasses in the oil reservoir permit oil

level observation. Normal oil level is between the middle of

the upper sight glass and the top of the lower sight glass

when the compressor is shut down. The oil level should be

visible in at least one of the 2 sight glasses during operation.

Oil sump temperature is displayed on the LID default

screen. Oil sump temperature ranges during compressor

operation between 100 to 120 F (37 to 49 C) [120 to 140 F

(49 to 60 C)].

The oil pump suction is fed from the oil reservoir. An

oil pressure relief valve maintains 18 to 25 psid (124 to

172 kPad) differential pressure in the system at the pump

discharge. This differential pressure can be read directly from

the Local Interface Device (LID) default screen. The oil pump

discharges oil to the oil filter assembly. This filter can be

valved closed to permit removal of the filter without drain-

ing the entire oil system (see Maintenance sections, pages

61 to 65, for details). The oil is then piped to the oil cooler.

This heat exchanger uses refrigerant from the condenser as

the coolant. The refrigerant cools the oil to a temperature

between 100 and 120 F (37 to 49 C).

As the oil leaves the oil cooler, it passes the oil pressure

transducer and the thermal bulb for the refrigerant expan-

sion valve on the oil cooler. The oil is then divided, with a

portion flowing to the thrust bearing, forward pinion bear-

ing, and gear spray. The balance then lubricates the motor

shaft bearings and the rear pinion bearing. The oil temper-

ature is measured as the oil leaves the thrust and forward

Fig. 3 — Refrigerant Motor Cooling and Oil Cooling Cycles

8