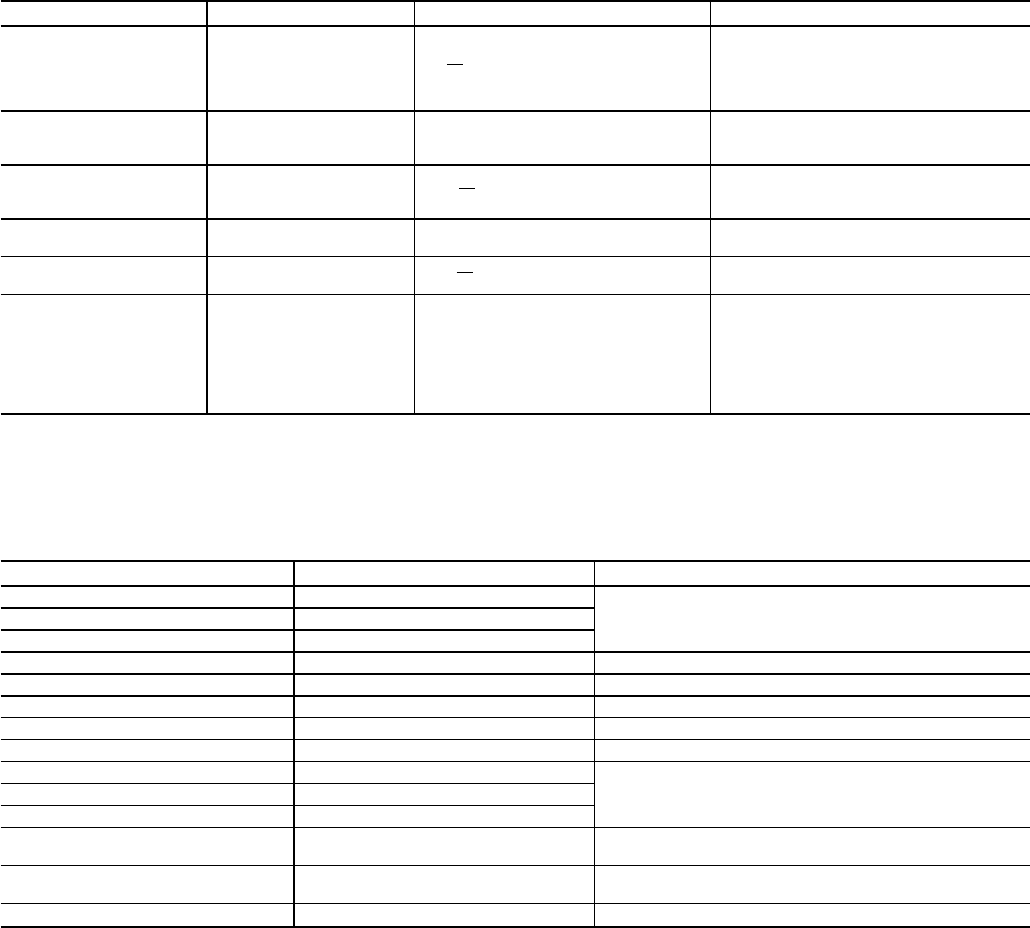

Table 9 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides (cont)

G. COMPRESSOR JUMPSTART AND REFRIGERANT PROTECTION

PRIMARY MESSAGE SECONDARY MESSAGE ALARMMESSAGE/PRIMARYCAUSE ADDITIONAL CAUSE/REMEDY

UNAUTHORIZED

OPERATION

UNIT SHOULD BE

STOPPED

CA P Emergency: Compressor

running without control authorization.

Compressor is running with more than

10% RLA and control is trying to shut it

down. Throw power off to compressor if

unable to stop. Determine cause before

repowering.

POTENTIAL FREEZE-UP

EVAP PRESS/TEMP

TOO LOW

ERT Emergency: Freeze-up

prevention.

Determine cause. If pumping refrigerant

out of chiller, stop operation and go over

pumpout procedures.

FAILURE TO STOP DISCONNECT POWER

RUN AUX Emergency: DISCON-

NECT POWER.

Starter and run and start contacts are

energized while control tried to shut

down. Disconnect power to starter.

LOSS OF

COMMUNCIATION

WITH STARTER

Loss of Communication with Starter:

Check chiller.

Check wiring from PSIO to SMM. Check

SMM module troubleshooting procedures.

STARTER CONTACT

FAULT

ABNORMAL 1CR OR

RUN AUX

1CR AUX Starter Contact Fault:

Check 1CR/1M aux. contacts.

Starter run and start contacts energized

while chiller was off. Disconnect power.

POTENTIAL FREEZE UP

COND PRESS/TEMP

TOO LOW

CRT [VALUE] exceeded limit of

[LIMIT]* Emergency: Freeze-up

prevention.

The condenser pressure transducer is

reading a pressure that could freeze the

water in the condenser tubes. Check for

condenser refrigerant leaks, bad trans-

ducers, or transferred refrigerant. Place

the unit in Pumpdown mode to eliminate

ALARM if vessel is evacuated.

*[LIMIT] is shown on the LID as the temperature, pressure, voltage, etc., set point predefined or selected by the operator as an override, alert, or

alarm condition. [VALUE] is the actual pressure, temperature, voltage, etc., at which the control tripped.

H. NORMAL RUN WITH RESET, TEMPERATURE, OR DEMAND

PRIMARY MESSAGE SECONDARY MESSAGE PROBABLE CAUSE/REMEDY

RUNNING — RESET ACTIVE 4-20MA SIGNAL

Reset program active based upon Config table setup.RUNNING — RESET ACTIVE REMOTE SENSOR CONTROL

RUNNING — RESET ACTIVE CHW TEMP DIFFERENCE

RUNNING — TEMP CONTROL LEAVING CHILLED WATER Default method of temperature control.

RUNNING — TEMP CONTROL ENTERING CHILLED WATER ECW control activated on Config table.

RUNNING — TEMP CONTROL TEMPERATURE RAMP LOADING Ramp loading in effect. Use Service1 table to modify.

RUNNING — DEMAND LIMITED BY DEMAND RAMP LOADING Ramp loading in effect. Use Service1 table to modify.

RUNNING — DEMAND LIMITED BY LOCAL DEMAND SETPOINT Demand limit setpoint is Ͻ actual demand.

RUNNING — DEMAND LIMITED BY 4-20MA SIGNAL

Demand limit is active based on Config table setup.RUNNING — DEMAND LIMITED BY CCN SIGNAL

RUNNING — DEMAND LIMITED BY LOADSHED/REDLINE

RUNNING — TEMP CONTROL HOT GAS BYPASS

Hot Gas Bypass is energized. See surge prevention

in the control section.

RUNNING — DEMAND LIMITED BY LOCAL SIGNAL

Active demand limit manually overridden or Status01

table.

RUNNING — TEMP CONTROL ICE BUILD MODE Chiller is running under Ice Build temperature control.

NOTE: See Legend on page 68.

71