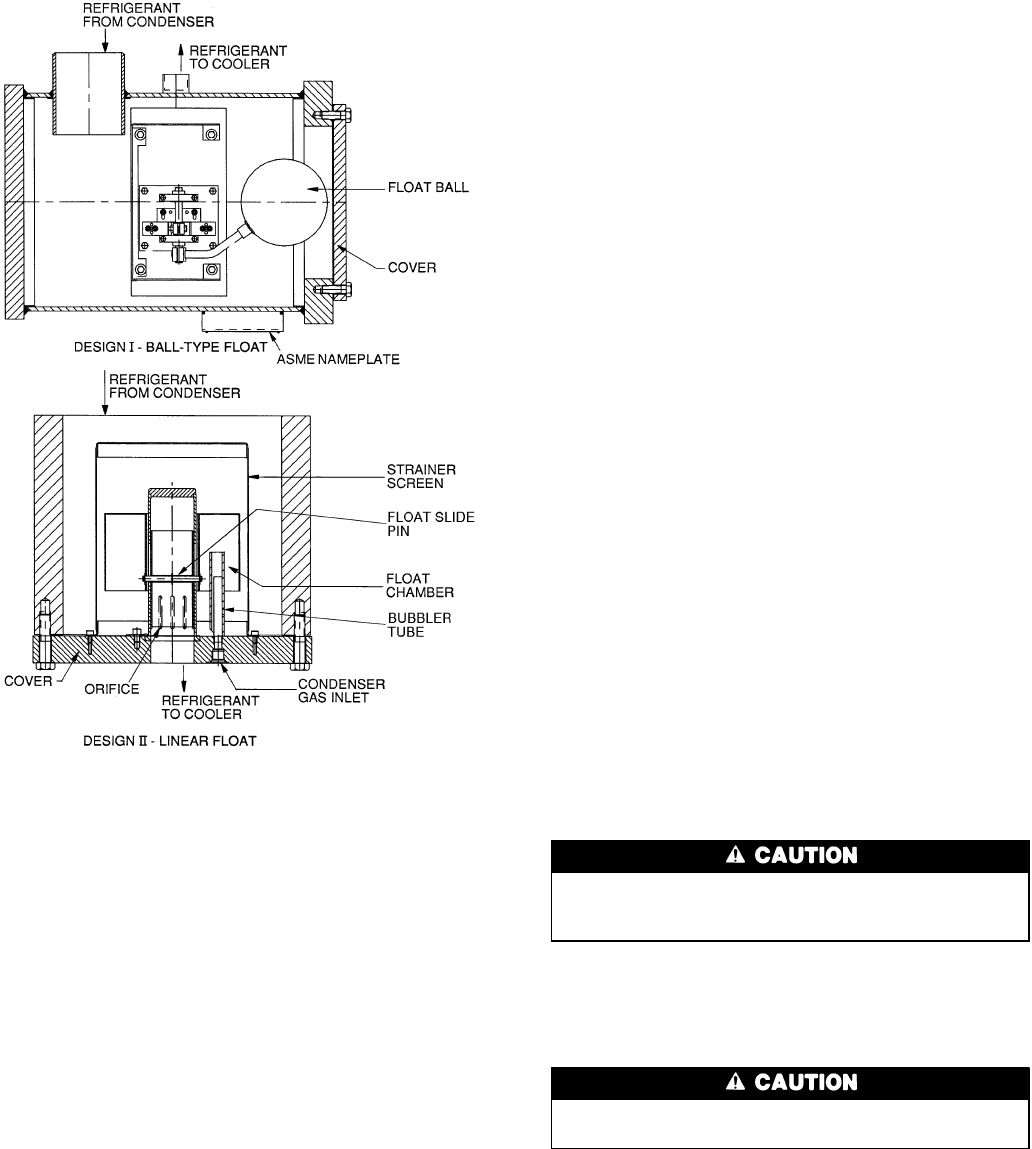

Inspect Refrigerant Float System — Perform

inspection every 5 years or when the condenser is opened

for service. Transfer the refrigerant into the cooler vessel or

into a storage tank. Remove the float access cover. Clean the

chamber and valve assembly thoroughly. Be sure that the

valve moves freely. Make sure that all openings are free of

obstructions. Examine the cover gasket and replace if nec-

essary. See Fig. 37 for views of both float valve designs. On

the linear float valve design, inspect orientation of the float

slide pin. It must be pointed toward the bubbler tube for proper

operation.

Inspect Relief Valves and Piping — The relief valves

on this chiller protect the system against the potentially dan-

gerous effects of overpressure. To ensure against damage

to the equipment and possible injury to personnel, these

devices must be kept in peak operating condition.

As a minimum, the following maintenance is required.

1. At least once a year, disconnect the vent piping at the

valve outlet and carefully inspect the valve body and

mechanism for any evidence of internal corrosion or rust,

dirt, scale, leakage, etc.

2. If corrosion or foreign material is found, do not attempt

to repair or recondition. Replace the valve.

3. If the chiller is installed in a corrosive atmosphere or the

relief valves are vented into a corrosive atmosphere, make

valve inspections at more frequent intervals.

Compressor Bearing and Gear Mainten-

ance —

The key to good bearing and gear maintenance is

proper lubrication. Use the proper grade of oil, maintained

at recommended level, temperature, and pressure. Inspect the

lubrication system regularly and thoroughly.

To inspect the bearings, a complete compressor teardown

is required. Only a trained service technician should remove

and examine the bearings. The cover plate on older com-

pressor bases was used for factory-test purposes, and is not

usable for bearing or gear inspection. The bearings and gears

should be examined on a scheduled basis for signs of wear.

The frequency of examination is determined by the hours of

chiller operation, load conditions during operation, and the

condition of the oil and the lubrication system. Excessive

bearing wear can sometimes be detected through increased

vibration or increased bearing temperature. If either symp-

tom appears, contact an experienced and responsible service

organization for assistance.

Inspect the Heat Exchanger Tubes

COOLER — Inspect and clean the cooler tubes at the end of

the first operating season. Because these tubes have internal

ridges, a rotary-type tube cleaning system is necessary to fully

clean the tubes. Upon inspection, the tube condition will

determine the scheduled frequency for cleaning, and will

indicate whether water treatment is adequate in the chilled

water/brine circuit. Inspect the entering and leaving chilled

water temperature sensors for signs of corrosion or scale.

Replace the sensor if corroded or remove any scale if found.

CONDENSER — Since this water circuit is usually an open-

type system, the tubes may be subject to contamination and

scale. Clean the condenser tubes with a rotary tube clean-

ing system at least once per year, and more often if the water

is contaminated. Inspect the entering and leaving condenser

water sensors for signs of corrosion or scale. Replace the

sensor if corroded or remove any scale if found.

Higher than normal condenser pressures, together with the

inability to reach full refrigeration load, usually indicate dirty

tubes or air in the chiller. If the refrigeration log indicates a

rise above normal condenser pressures, check the condenser

refrigerant temperature against the leaving condenser water

temperature. If this reading is more than what the design

difference is supposed to be, then the condenser tubes may

be dirty, or water flow may be incorrect. Because HCFC-22

and HFC134-a are high-pressure refrigerants, air usually does

not enter the chiller, rather, the refrigerant leaks out.

During the tube cleaning process, use brushes especially

designed to avoid scraping and scratching the tube wall. Con-

tact your Carrier representative to obtain these brushes. Do

not use wire brushes.

Hard scale may require chemical treatment for its pre-

vention or removal. Consult a water treatment specialist

for proper treatment.

Water Leaks — Water is indicated during chiller opera-

tion by the refrigerant moisture indicator (Fig. 2A or 2B) on

the refrigerant motor cooling line. Water leaks should be re-

paired immediately.

Chiller must be dehydrated after repair of water leaks.

See Chiller Dehydration section, page 47.

Fig. 37 — 19XL Float Valve Designs

64