19XL CHILLER EQUALIZATION WITH PUMPOUT

UNIT — The following procedure describes how to equal-

ize refrigerant pressure on an isolated 19XL chiller using the

pumpout unit.

1. Access the TERMINATE LOCKOUT mode in the Con-

trol Test.

2. Turn on the chilled water and condenser water pumps to

prevent possible freezing.

3. Open valve 4 on the pumpout unit and open valves 1a

and 1b on the chiller cooler and condenser, Fig. 27 and

28. Slowly open valve 2 on the pumpout unit to equalize

the pressure. This process will take approximately

15 minutes.

4. Once the pressures have equalized, the discharge isola-

tion valve, cooler isolation valve, optional hot gas bypass

isolation valve, and the refrigerant isolation valve can be

opened. Close valves 1a and 1b, and all pumpout unit

valves.

Whenever turning the discharge isolation valve, be

sure to reattach the valve locking device. This will

prevent the valve from opening or closing during serv-

ice work or during chiller operation.

The full refrigerant charge on the 19XL will vary with

chiller components and design conditions, indicated on the

job data specifications.An approximate charge may be found

by adding the condenser charge to the cooler charge listed in

Table 8.

Always operate the condenser and chilled water pumps

during charging operations to prevent freeze-ups. Use the

Control Test Terminate Lockout to monitor conditions and

start the pumps.

If the chiller has been shipped with a holding charge, the

refrigerant will be added through the refrigerant charging valve

(Fig. 27 and 28, valve 7) or to the pumpout charging con-

nection. First evacuate the nitrogen holding charge from the

vessels. Charge the refrigerant as a gas until the system pres-

sure exceeds 68 psig (469 kPa); [35 psig (141 kPa)]. After

the chiller is beyond this pressure the refrigerant should be

charged as a liquid until all of the recommended refrigerant

charge has been added.

TRIMMING REFRIGERANT CHARGE — The 19XL is

shipped with the correct charge for the design duty of the

chiller. Trimming the charge can be best accomplished when

design load is available. To trim, check the temperature

difference between leaving chilled water temperature and

cooler refrigerant temperature at full load design conditions.

If necessary, add or remove refrigerant to bring the tempera-

ture difference to design conditions or minimum differential.

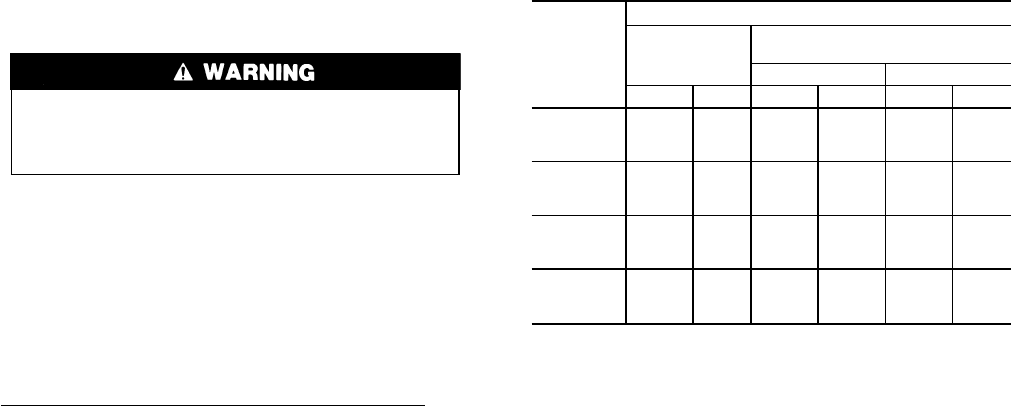

Table 8 — Refrigerant Charges*

COOLER

SIZE

19XL TOTAL REFRIGERANT CHARGE

Design I

Chiller

Design II

Chiller

HCFC-22 HFC-134a

lb kg lb kg lb kg

40 1420 640 1100 499 900 409

41 1490 680 1150 522 950 431

42 1550 700 1250 568 1000 454

43 1600 730 1350 613 1050 477

50 1850 840 1500 681 1100 499

51 1900 860 1600 726 1200 545

52 1980 900 1750 795 1300 590

53 2050 930 1850 840 1350 613

55 — — 1900 863 1550 704

56 — — 2200 999 1650 749

57 — — 2500 1135 1750 795

58 — — 2700 1226 1900 863

*Design Ichillers useHCFC-22. Design IIchillers useeither HCFC-22

or HFC-134a.

NOTES:

1. The size of the cooler determines refrigerant charge for the entire

chiller.

2. Design I chillers have float chambers.

3. Design II chillers have linear floats.

54