100

6

6

mm) or more, replace the entire head. If

plug gauge is not available, see Section

12 - Engine Specifications for the valve

guide reject dimension.

3. If guides are replaced, or the original

guides still meet specifications, use Finish

Reamer #19066 and Reamer Guide

#19191 to ensure proper sizing and to

clean out the guides. Thoroughly clean all

reaming debris from cylinder head.

4. Inspect valves for wear or damage.

Replace if necessary.

NOTE: Valve faces can be resurfaced on a

commercially available valve grinder. However,

Briggs & Stratton does not recommend this

practice because the quality of the resurfacing

may be insufficient. Instead, valve replacement

is recommended.

5. Oil the intake valve guide and intake valve

stem, then insert valve into head.

6. Using Valve Lapping Tool #19258 and

Lapping Compound #94150, lap valve and

seat together to assure a good sealing

surface. Remove valve, the repeat

procedure for the exhaust valve.

7. Thoroughly clean both valves and cylinder

head of all lapping compound residue.

Assemble Cylinder Head

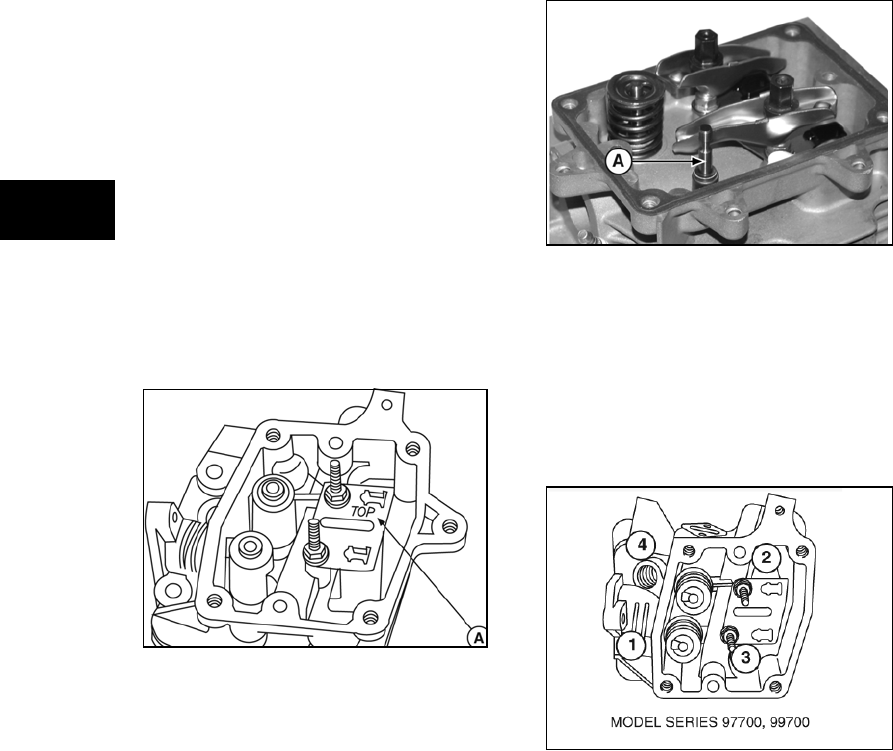

1. Install new plastic push rod guides (A,

Figure 23) into the cylinder head plate.

Figure 23

2. Using new plate gasket, install the cylinder

head plate. Torque screws to values listed

in Section 12 - Engine Specifications.

3. Lightly coat valve stems with Valve Guide

Lubricant #93963. then insert valves into

cylinder head. Do not get lubricant on

valve face, valve seat, or exposed end of

valve stem.

4. Oil inside diameter of new stem seal/

washer and install on intake valve stem.

Slide seal down against head plate or

cylinder head.

5. Support valve side of cylinder head on

clean shop rags. Place valve springs and

valve spring retainers over valve stems.

Using thumbs, press against each retainer

until it securely locks into groove in valve

stem (A, Figure 24).

Figure 24

Install Cylinder Head

1. Coat threads of all cylinder head screws

with Valve Guide Lubricant #93963.

2. Using a new head gasket, install cylinder

head on cylinder and start screws by

hand. Step-torque screws in sequence

shown in Figures 25, 26, 27, and 28 until

final torque value is achieved. Torque

screws to value listed in Section 12 -

Engine Specifications.

Figure 25