137

10

10

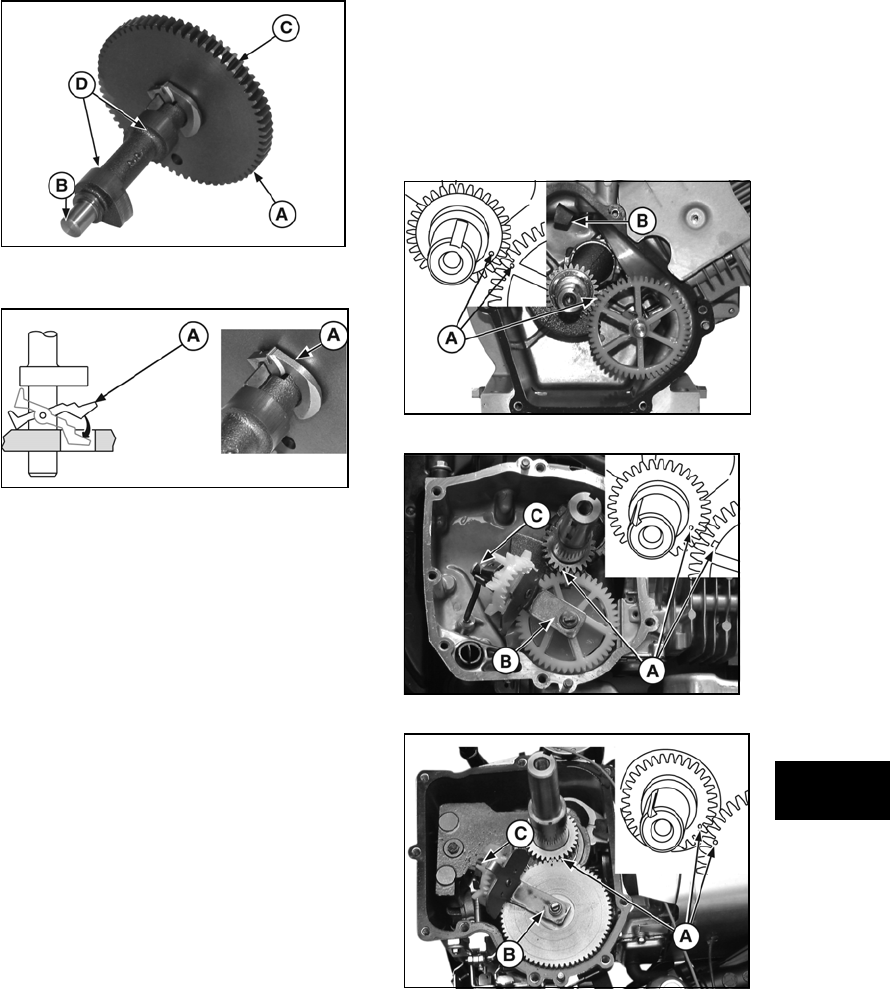

Figure 4

Figure 5

2. Using a dial caliper, measure the journal

diameters and cam lobes. Compare

results to values listed in Section 12 -

Engine Specifications. If wear exceeds the

reject dimensions, replace the camshaft.

Install Crankshaft and Camshaft

1. Lubricate the cylinder bearing/oil seal with

engine oil.

2. Install intake and exhaust valve tappets.

3. Support both ends of the crankshaft, and

carefully install into the cylinder.

NOTE: The counterbalance system, if equipped,

must be assembled to the crankshaft before

installing into the cylinder.

4. Assemble connecting rod assembly to

crankshaft.

5. Install the timing gear to the crankshaft

with timing mark out. The flange of the

gear must face the counterweight link, if

equipped.

6. Install camshaft, making sure tappets clear

cam lobes. Timing marks

(A, Figures 6, 7, 8) must align.

7. On horizontal crankshaft engines, make

sure the paddle on the governor shaft

(B, Figure 6) is rotated in line with the

governor cup inside the crankcase cover.

8. On vertical crankshaft engines, assemble

governor gear/oil slinger (B, Figures 7 and

8) to camshaft. Make sure the paddle on

the governor shaft is contacting the

governor cup (C).

Figure 6

Figure 7

Figure 8