149

9

11

Engine Specifications. If clearance is

greater than shown the piston must be

replaced.

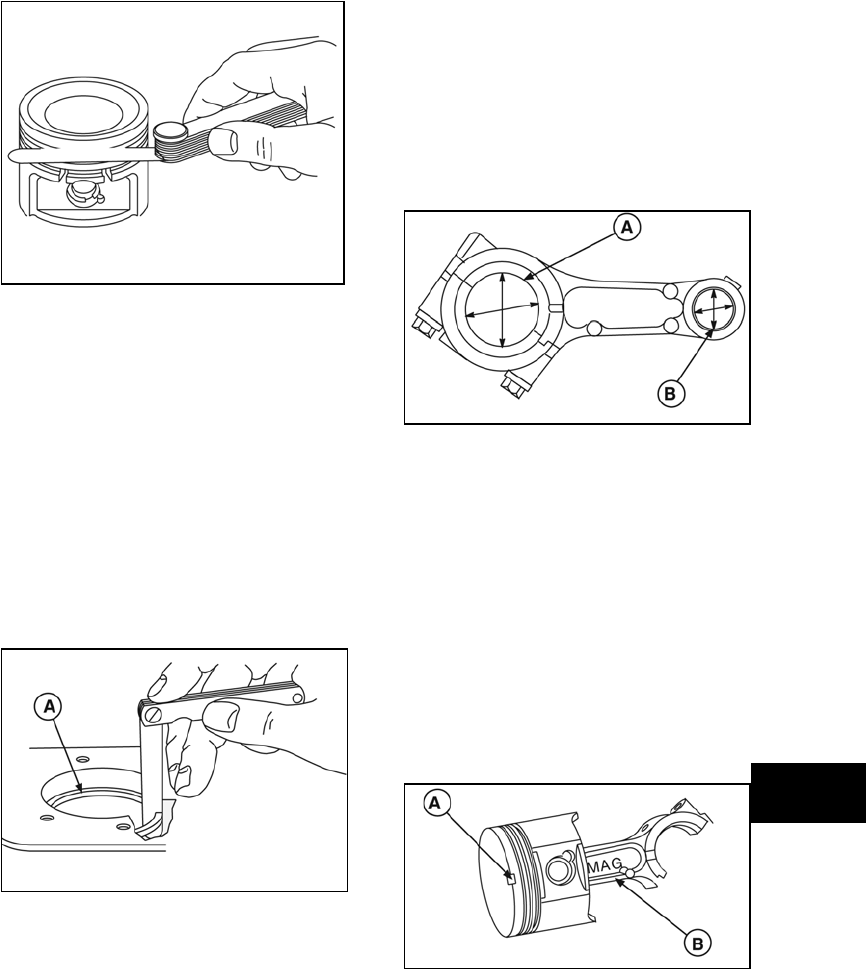

Figure 4

Check Ring End Gap

It is recommended that the entire ring set be

replaced when servicing the piston and/or

cylinder bore. However, the original rings can be

re-used if they are not damaged and are

checked as follows:

1. Clean all carbon from the rings and the

cylinder bore.

2. Insert an original ring (A, Figure 5)

approximately one inch down into the

cylinder bore.

3. Check end gap with feeler gauge.

Compare with reject dimensions listed in

Section 12 - Engine Specifications. If gap

of any of the rings exceeds the reject

dimension, all rings should be replaced.

Figure 5

Check Connecting Rod

If the crankpin bearing (A, Figure 6) or the piston

pin bearing (B) is scored, the rod must be

replaced.

1. Reinstall rod cap and bolts on rod.

2. Using a dial caliper or plug gauge,

measure the two bearing diameters.

Compare with reject dimensions listed in

Section 12 - Engine Specifications. If

either bearing exceeds the reject

dimensions, the rod must be replaced.

3. Remove rod bolts and rod cap. Set aside.

Figure 6

Assemble

1. Install a pin retainer into one groove in

piston bore. Skip this step if piston has a

shoulder stop on one side.

2. Oil the piston pin bore, connecting rod pin

bore, and the pin. Insert rod into piston,

then slip pin through piston and rod bores

until it seats against the retainer or

shoulder stop.

NOTE: The notch or arrow (A, Figure 7) on the

piston and “MAG” on the rod (B) must face the

same direction. When installed in engine, the

notch will face the flywheel.

Figure 7