10

1

1

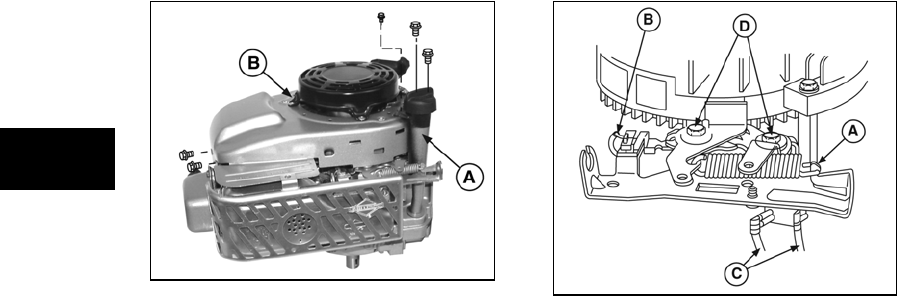

Figure 3

6. Using a torque wrench and socket to fit the

flywheel nut, turn flywheel clockwise with

brake engaged. While turning at a steady

rate, torque reading should be 26 lb.-in.

(3 Nm) or higher.

7. If reading is low, check thickness of brake

pad. Replace brake assembly if thickness

is less than 0.09” (2.28mm).

8. If brake pad thickness is acceptable,

adjust control cable to position pad closer

to flywheel when safety control is in RUN

position.

9. Replace brake assembly if correct

adjustment cannot be made.

Inspect Brake and Switches

1. Disconnect spring from brake anchor

(A, Figure 4).

2. Disconnect stop switch wire from stop

switch (B). If engine is equipped with an

electric starter, disconnect both wires from

the starter interlock switch (C).

3. Remove two screws (D) from brake

bracket and remove bracket.

Figure 4

4. Inspect brake pad on brake lever. Replace

brake assembly if thickness is less than

0.09” (2.28mm).

5. Test stop switch as described in Section 2.

6. Test electric starter interlock switch as

described in Section 2.

Assemble Flywheel Brake

1. Install brake assembly on cylinder and

torque mounting screws to values listed in

Section 12 - Engine Specifications.

2. Install stop switch wire and bend end of

wire 90°. Install wires on interlock switch, if

equipped.

3. Install brake spring.

4. Actuate brake system to ensure proper

movement, then test brake torque as

previously described.

5. Install blower housing/rewind assembly,

install dipstick tube and dipstick, and

install fuel tank and static guard. Torque

all screws to values listed in Section 12 -

Engine Specifications.