45

2

2

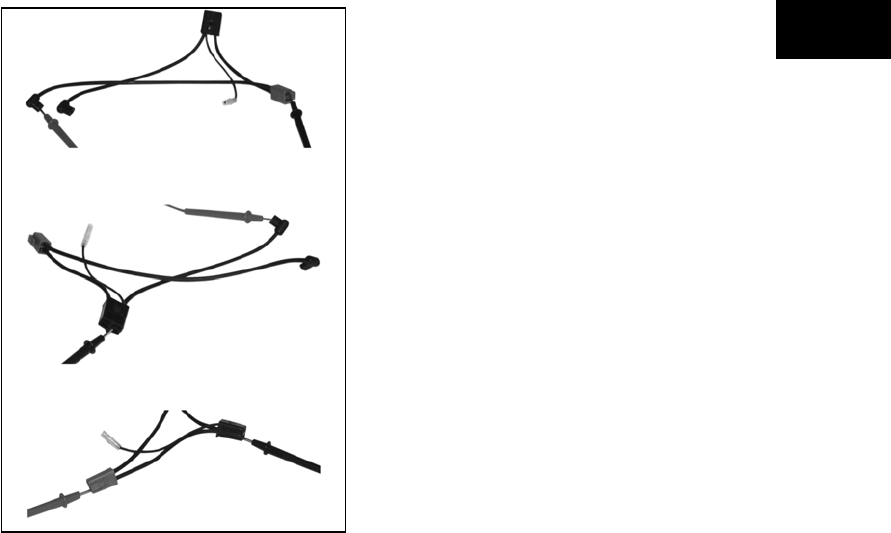

Test Interlock Switch Wiring

1. Disconnect interlock switch wires from

spade terminals on switch and at starter

motor connection.

2. Set meter to Ohms position.

3. Connect one meter test lead to the end of

one wire connector and other test lead to

the opposite connector in the same wire

(Figure 37). Meter should read low or no

resistance.

Figure 37

4. Move the wire inside the connector. Meter

should not change value.

5. Replace or repair wiring if there is

intermittent or no continuity. Repeat for

each wire in the harness.

12 Volt DC Starter Motor

Model Series 120000, 150000, 200000,

210000, 280000, 310000, 330000

These starter motors were produced in three

sizes to provide different cranking speeds and

torque. The length of the motor housing

determines the output as noted in the following

procedures.

Check Starter Motor Drive and Clutch

When starter switch is activated, pinion gear

should rise, engage flywheel ring gear, and crank

engine. The pinion gear must rotate

counterclockwise, as viewed from gear. If starter

motor drive does not react properly, check helix

and pinion gear for free operation. If the pinion

gear sticks, clean the helix and gear with a mild

solvent and compressed air. If the pinion

continues to stick, replace the entire starter drive

assembly.

NOTE: Do not oil the pinion gear or clutch helix.

The starter motor clutch is designed to prevent

damage from shock loads such as engine

backfire. If clutch slips while cranking, replace

the entire starter drive assembly.

Test Starter Motor

1. Clamp starter motor test fixture in vise.

2. Remove starter motor from engine and

mount to fixture.

NOTICE:

Do not clamp motor housing in a vise

or strike with a hammer. Starter motors contain

ceramic magnets that can be damaged if the

motor housing is hit, deformed, or dented.

3. Set meter to DC Amps position.

4. Connect the optional starter switch

(A, Figure 38), starter motor, battery (F),

black lead (C), red lead (D), shunt (E), and

tachometer (B).