44

2

2

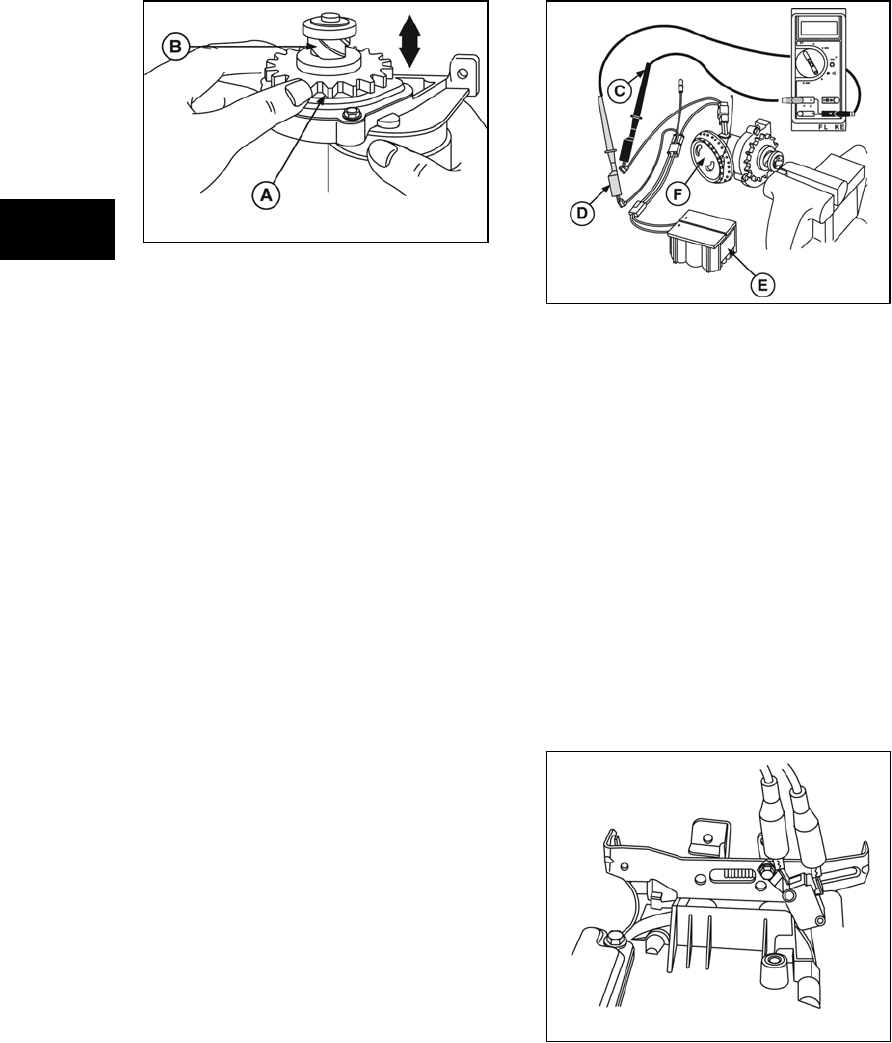

Figure 34

If the pinion gear sticks, clean the helix and gear

with a mild solvent and compressed air. If the

pinion continues to stick, replace the entire

starter drive assembly.

NOTE: Do not oil the pinion gear or helix.

The starter motor clutch is designed to prevent

damage from shock loads such as engine

backfire. If clutch slips while cranking, replace

the entire starter drive assembly.

Test Starter Motor

1. Clamp starter motor test fixture in vise.

2. Remove starter motor from engine and

mount to fixture (Figure 35).

NOTICE: Do not clamp motor housing in a vise

or strike with a hammer. Most starter motors

contain ceramic magnets that can be damaged if

the motor housing is hit, deformed, or dented.

3. Set meter to DC Amps position. Connect

the black test lead (C), red test lead (D),

starter motor, battery (E), and meter as

shown in Figure 35.

Figure 35

4. Using Tachometer #19200 (F), spin the

starter motor and note RPMs and

amperage draw. A starter motor in good

condition will be:

• 1400 RPM (minimum)

• 9 Amps (maximum)

If starter motor is not within specifications, it must

be replaced.

Test Interlock Switch

1. Disconnect interlock switch wires from

spade terminals on switch.

2. Set meter to Ohms position.

3. Connect meter test leads to two spade

terminals of switch (Figure 36). Meter

should read no continuity. If switch fails,

replace the switch. Push switch lever in

until it clicks. Meter should read low

resistance. If switch fails, replace the

switch.

Figure 36