26

2

2

2) Check Carburetion

Before making a carburetion check, be sure the

fuel tank has an ample supply of fresh, clean

gasoline.

Be sure the shutoff valve, if equipped, is open

and fuel flows freely through the fuel line. If fuel

fails to flow or is slow, check for plugged fuel cap

vent, fuel line restriction or plugged fuel filter.

Be sure throttle and choke controls are properly

adjusted.

If engine cranks but will not start, remove and

inspect the spark plug.

If plug is wet, look for:

• Over choking

• Excessively rich fuel mixture

• Water in fuel

• Float needle valve stuck open

• Plugged air cleaner

• Fouled spark plug

If plug is dry, look for:

• Leaking carburetor or intake manifold

gaskets

• Gummy or dirty carburetor, fuel filter, fuel

lines or fuel tank

• Float needle valve stuck closed

• Inoperative fuel pump (if equipped)

• Inoperative fuel shut off solenoid (if

equipped)

A simple check to determine if the fuel is getting

to the combustion chamber through the

carburetor is to remove the spark plug and pour

a small quantity of gasoline through the spark

plug hole. Replace the plug. If the engine fires a

few times and then stops, look for the same

conditions as for a dry plug.

Testing Fuel Shut Off Solenoid

The fuel shut off solenoid is controlled by the

equipment ignition switch. With the switch OFF,

the solenoid plunger closes, stopping the fuel

flow at the fixed main jet. With the switch in the

ON and START positions, the solenoid plunger

opens, allowing normal fuel flow. If operating

properly, the solenoid will click when the switch

is turned ON and OFF.

If solenoid does not click, the problem could be

the equipment wiring, engine wiring or the

solenoid. To determine which is the problem,

perform the following tests in the order shown.

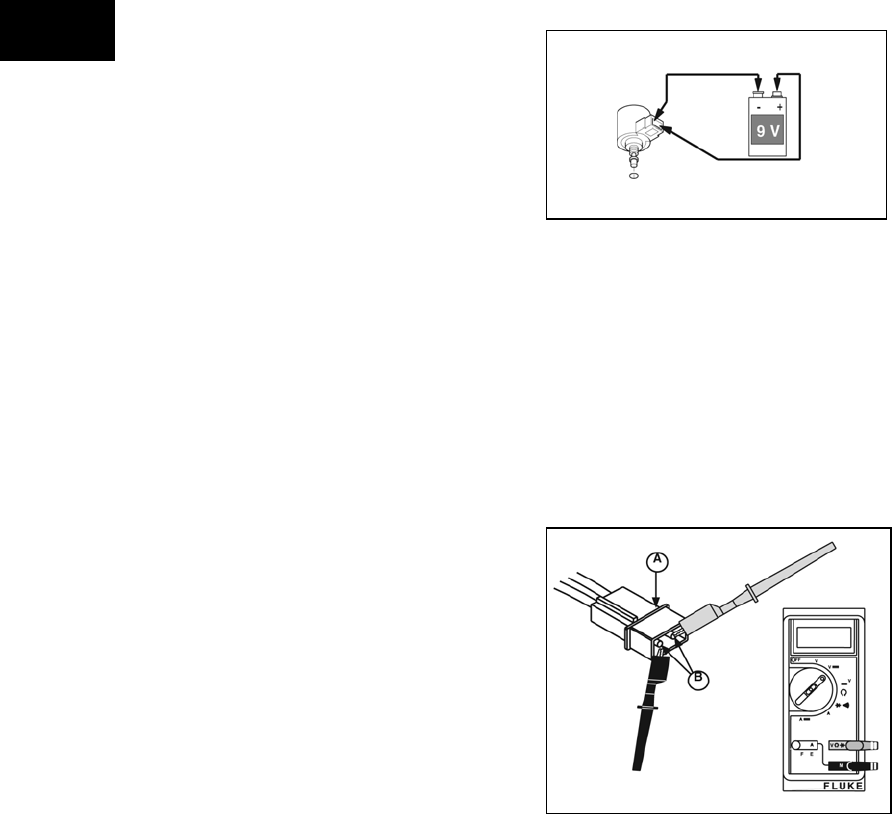

Solenoid Plunger Test

NOTE: The solenoid requires a minimum of 9

Volts DC to function.

1. Remove the fuel shut off solenoid from the

carburetor.

2. Place a jumper wire on either terminal of a

9 Volt battery and on one of the pins of the

solenoid connector.

3. Place another jumper wire on the other pin

in the solenoid connector and on the other

terminal on the battery (Figure 3).

Figure 3

• Plunger should retract freely, or with very

light fingertip pressure.

• When battery connection is removed,

plunger should extend.

• Replace solenoid if plunger sticks or

does not move.

Solenoid Wiring Test

1. Set multimeter to DC Volts position.

2. With key switch OFF, disconnect solenoid

wiring connector (A, Figure 4).

3. Attach meter test leads (B) to pins inside

wiring connector.

Figure 4