48

Alarm state is reset when the smoke detector alarm

condition is cleared and reset at the smoke detector in the

unit.

Connecting Discrete Inputs

Filter Status

The filter status accessory is a field--installed accessory.

This accessory detects plugged filters. When installing

this accessory, the unit must be configured for filter status

by setting MENU

→

Config

→

Inputs

→

input3,5,8,or9

to Filter Status and normally open (N/O) or normally

closed (N/C). Input 8 or 9 is recommended for easy of

installation. Refer to Fig. 59 and Fig. 60 for wire

terminations at J5.

Fan

Status

The fan status accessory is a field--installed accessory.

This accessory detects when the indoor fan is blowing air.

When installing this accessory, the unit must be

configured for fan status by setting

MENU

→

Config

→

Inputs

→

input3,5,8,or9to Fan

Status and normally open (N/O) or normally closed (N/C).

Input 8 or 9 is recommended for easy of installation. Refer

to Fig. 59 and Fig. 60 for wire terminations at J5.

Remote

Occupancy

The remote occupancy accessory is a field--installed

accessory. This accessory overrides the unoccupied mode

and puts the unit in occupied mode. When installing this

accessory, the unit must be configured for remote

occupancy by setting MENU

→

Config

→

Inputs

→

input 3,

5, 8, or 9 to Remote Occupancy and normally open (N/O)

or normally closed (N/C).

Also set MENU

→

Schedules

→

occupancy source to DI

on/off. Input 8 or 9 is recommended for easy of

installation. Refer to Fig. 59 and Table 21 for wire

terminations at J5.

Power Exhaust (output)

Connect the accessory Power Exhaust contactor coil(s) per

Fig. 66.

Power Exhaust

J11-3

C

THERMOSTAT

PEC

TAN

GRA

LCTB

C08464

Fig. 66 -- RTU--MP Power Exhaust Connections

Space Relative Humidity Sensor -- The RH sensor is not

used with 48TC models at this time.

Communication Wiring -- Protocols

General

Protocols are the communication languages spoken by

control devices. The main purpose of a protocol is to

communicate information in the most efficient method

possible. Different protocols exist to provide different

kinds of information for different applications. In the BAS

application, many different protocols are used, depending

on manufacturer. Protocols do not change the function of

a controller; just make the front end user different.

The RTU--MP can be set to communicate on four different

protocols: BACnet, Modbus, N2, and LonWorks. Switch 3

(SW3) on the board is used to set protocol and baud rate.

Switches 1 and 2 (SW1 and SW2) are used to set the

board’s network address. See Fig 67 for the switch setting

per protocol. The 3rd party connection to the RTU--MP is

through plug J19. Refer to the RTU --MP 3rd Party

Integration Guide for more detailed information on

protocols, 3rd party wiring, and networking.

NOTE: Power must be cycled after changing the SW1--3

switch settings.

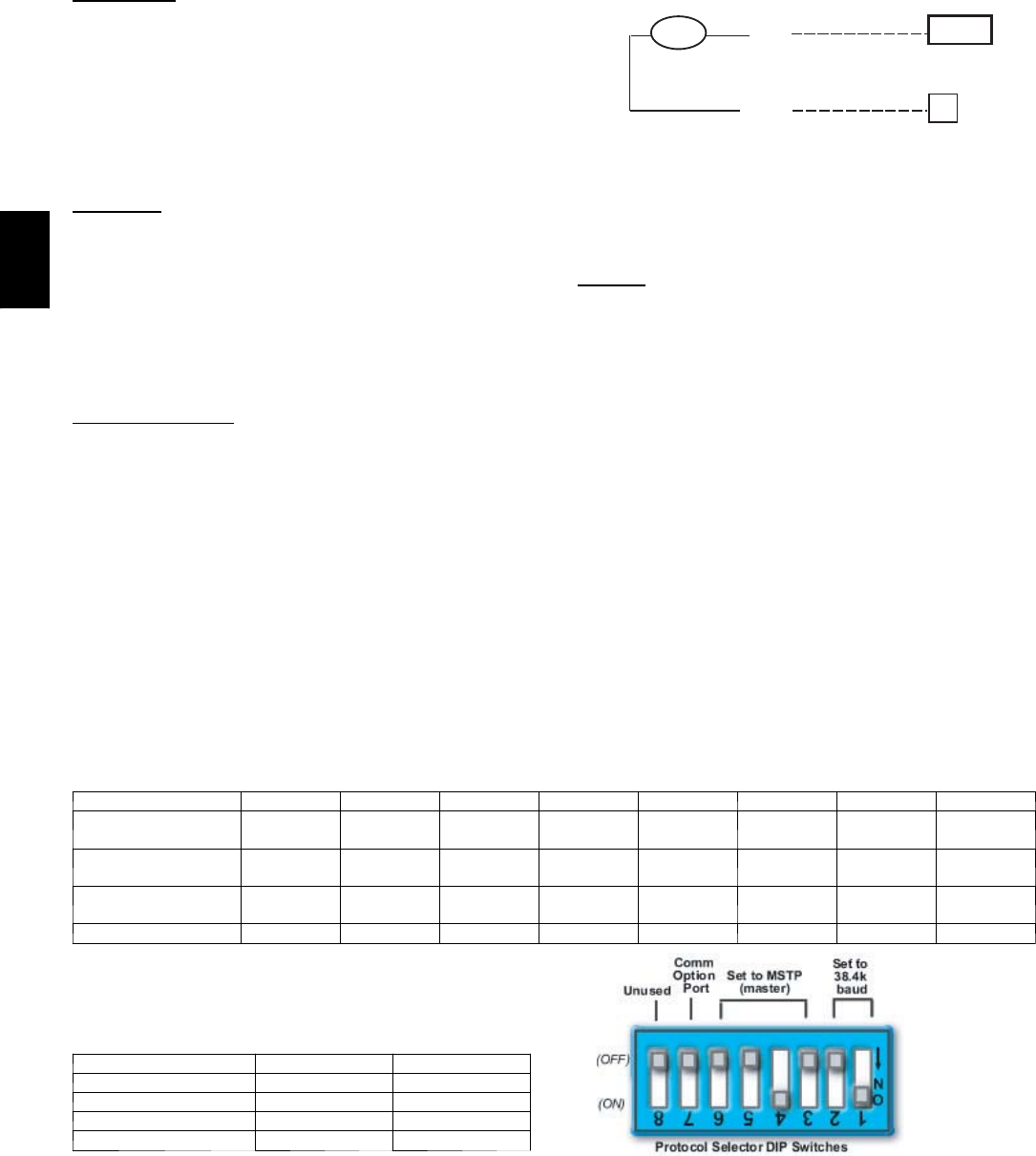

SW3 Protocol Selection

PROTOCOL DS8 DS7 DS6 DS5 DS4 DS3 DS2 DS1

BACnet MS/TP

(Master)

Unused OFF OFF OFF ON OFF Select Baud Select Baud

Modbus

(Slave)

Unused OFF OFF ON ON OFF Select Baud Select Baud

N2

(Slave)

Unused OFF OFF OFF ON ON OFF OFF

LonWorks Unused ON ON OFF ON OFF OFF OFF

NOTE:

DS = Dip Switch

BACnet MS/TP SW3 example shown

Baud Rate Selections

BAUD RATE DS2 DS1

9600 OFF OFF

19,200 ON OFF

38,400 OFF ON

76,800 ON ON

C07166

Fig. 67 -- RTU--MP SW3 Dip Switch Settings

48TC