55

7. Verify proper wiring between the BAS and the con-

troller.

8. Verify that the BAS is reading or writing to the proper

Modbus register numbers on the controller. Download

the latest points list for the controller to verify.

9. Verify that the BAS is sending his requests to the

proper slave address of our controller.

NOTE: See RTU--MP 3rd Party Integration Guide (or

alternatively Form 48--50H--T--1T, Appendix) for Modbus

Protocol Conformance Statement.

N2

1. Verify that the BAS and controller are both set to

speak the N2 protocol. The protocol of the controller

is set via SW3 (switches 3, 4, 5, and 6). The protocol

can also be verified by getting a Modstat of the con-

troller through the BACview. Hit the “FN” key and

the ’.’ key at the same time to pull up a Modstat.

Scroll to the bottom of the page and there is a section

entitled ”Network Communications.” The active pro-

tocol and baud rate will be shown in this section.

2. Verify that the BAS and controller are set for 9600

baud. The baud rate of the controller is set via SW3

(switches 1 and 2). The baud rate can also be verified

via the BACview by obtaining a Modstat (see above).

3. Verify that the BAS is configured to speak 2--wire

EIA--485 to the controller. The BAS may have to con-

figure jumper or DIP switches on their end.

4. Verify that the BAS and the controller have the same

communication settings (8 data bits, No Parity, and 1

stop bit).

5. Verify that the controller has a unique N2 slave ad-

dress on the N2 bus. The controller’s N2 slave ad-

dress is set by its rotary address switches.

6. Verify proper wiring between the BAS and the con-

troller.

7. Verify that the BAS is reading or writing to the proper

network point addresses on the controller. Download

the latest points list for the controller to verify.

8. Verify that the BAS is sending his requests to the

proper slave address of our controller.

NOTE: See RTU--MP 3rd Party Integration Guide (or

alternatively Form 48--50H--T--1T Appendix) for N2

Protocol Conformance Statement.

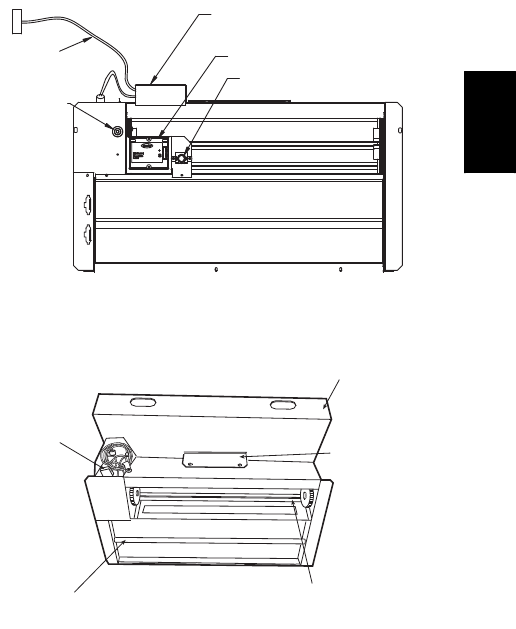

ECONOMIZER SYSTEMS

The 48TC units may be equipped with a factory--installed

or accessory (field--installed) economizer system. Two

types are available: with a logic control system

(EconoMi$er IV) and without a control system

(EconoMi$er2, for use with external control systems such

as PremierLink). See Fig. 70 and Fig. 71 for component

locations on each type. See Fig. 72 and Fig. 73 for

economizer section wiring diagrams.

Both EconoMi$ers use direct--drive damper actuators.

ECONOMI$ER IV

CONTROLLER

OUTSIDE AIR

TEMPERATURE SENSOR

LOW AMBIENT

SENSOR

A

CTUATOR

WIRING

HARNESS

C06021

Fig. 70 -- EconoMi$er IV Component Locations

ECONOMI$ER2

PLUG

BAROMETRIC

RELIEF

DAMPER

OUTDOOR

AIR HOOD

HOOD

SHIPPING

BRACKET

GEAR DRIVEN

DAMPER

C06022

Fig. 71 -- EconoMi$er2 Component Locations

48TC