Viper Service Manual

© 2010, IMI Cornelius Inc. - 9 - Publication Number: 621360041TBSER

An overall schematic of the three delivery systems contained in the unit are

shown in Figure 5. The CO

2 system is on top, the water system is in the middle

and the syrup system is at the bottom of the diagram. The CO

2 system interacts

with both the water and syrup systems. It provides pressure and carbonation for

the syrup/water product mix.

CO2 System

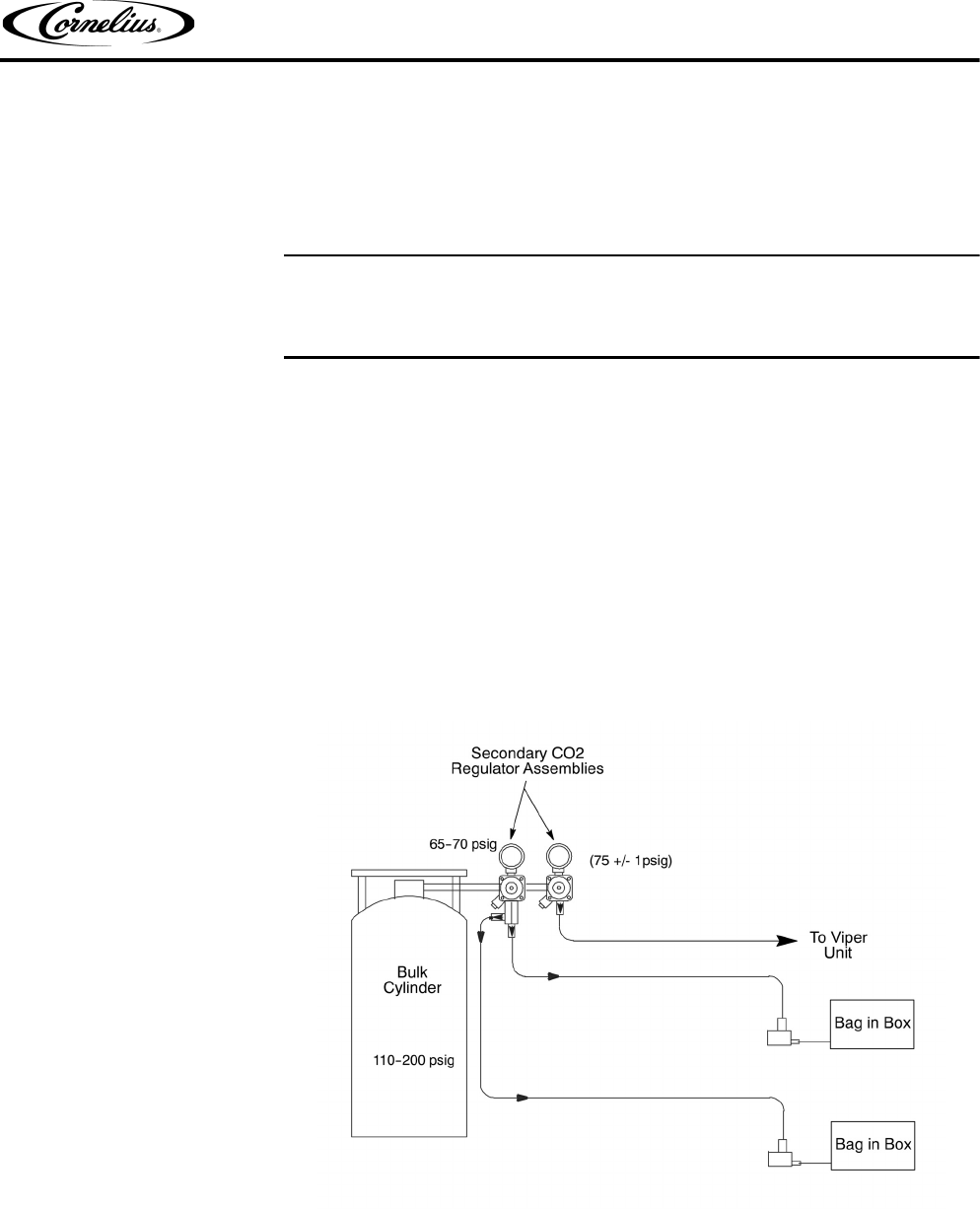

A CO2 tank or bulk CO2 supply delivers carbon dioxide gas (CO2) to an adjust-

able secondary CO

2 regulator assembly that is attached to the tank as shown in

Figure 3 and Figure 4. The CO

2 system also supplies CO2 to the water boost

pump, the expansion tank regulator and the secondary CO

2 tank regulators.

CO

2 enters the expansion tank regulator and is reduced to approximately 30

psig to feed holding pressure on the expansion tank. This provides a force to

work against the barrel pressure when the product freezes and expands.

CO

2 also enters the secondary regulators. These regulators are used to adjust

barrel overrun/expansion for various products. The pressure settings for various

types of syrup are shown in Table 1. Overrun CO

2 pressure is applied to the CO2

control solenoids through preset orifices and on to the in-line check valves.

From the in-line check valve, the CO

2 flows into the product line.

Figure 3. Typical Bulk Cylinder CO2 Connection