Viper Service Manual

© 2010, IMI Cornelius Inc. - 35 - Publication Number: 621360041TBSER

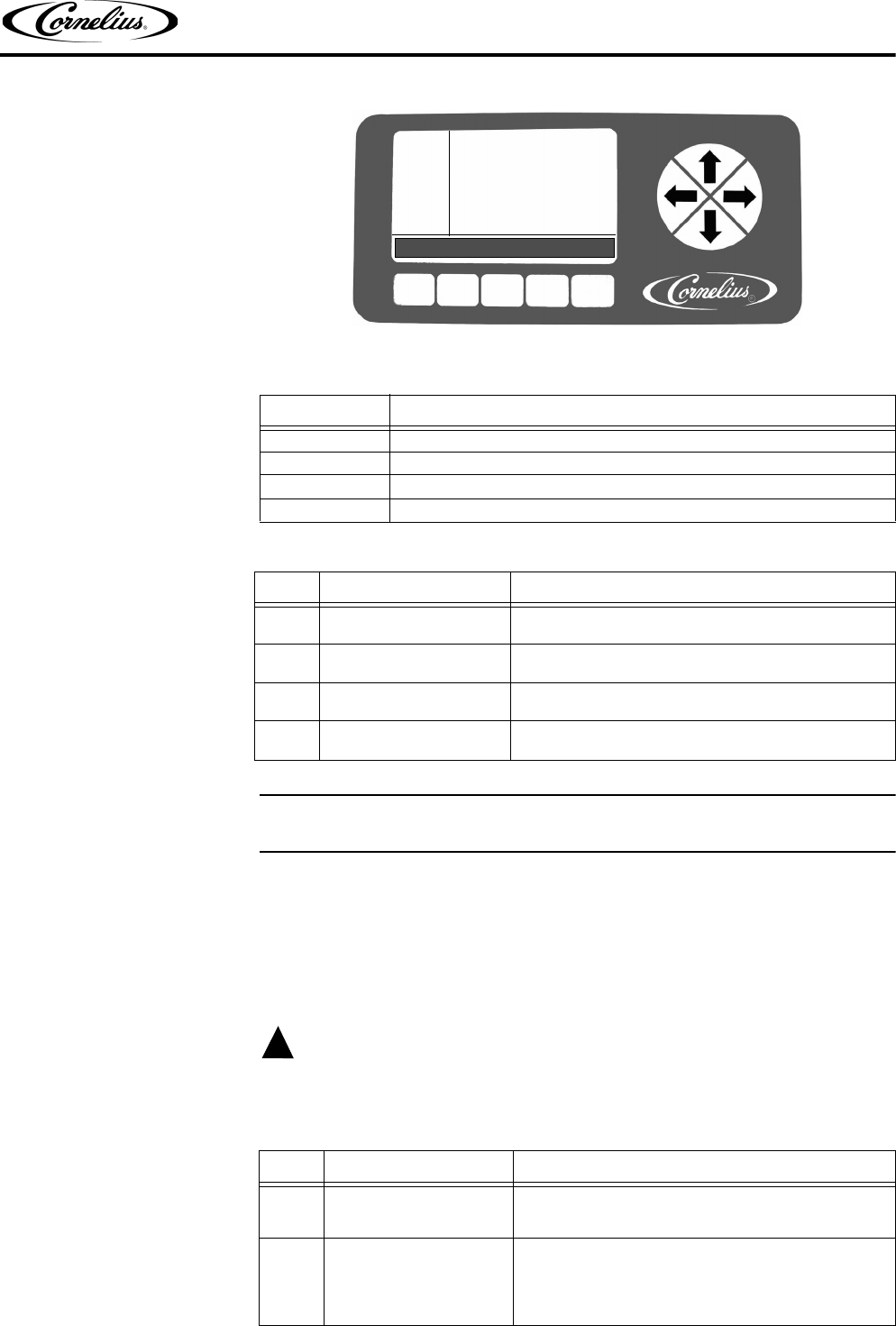

Figure 28. Motor Setup Screen

Calibrating a Motor

Calibration of motors is typically required when a motor or any associated barrel

components (i.e., scraper blades, seal, faceplate, etc.) is removed or replaced.

Calibration establishes a new baseline for the motor assembly. This allows the

system to determine proper viscosity settings for the new motor. When a new

motor is installed in the unit or any of the barrel components are changed or

adjusted, the motor should be calibrated by performing the procedure described

in Table 31.

!

CAUTION:

Calibration must be performed when the product in the barrel is com-

pletely liquid. There must not be any ice on the scraper blade.

Table 29

Button Description

BACK Returns the display to the Select menu

CAL Verifies the motor settings of a new motor.

- Decrements the highlighted field

+ Increments the highlighted field

Table 30

Step Action Procedure

1

Set barrel for Motor Type From the Maintenance menu (Figure 20), open the

Motor Setup menu, shown in Figure 28.

2

Select the barrel Use the Up and Down arrows to highlight the desired

barrel

3

Select the proper motor

type

Press the + or - buttons at the bottom of the display to

select the proper motor type

4

Complete the procedure Press the BACK button at the bottom of the display to

save the settings and return to the Setup menu.

MOTOR

SETUP

12:51P

MAR 04

#1 MOTOR TYPE 1

#2 MOTOR TYPE 2

BACK CAL - +

Table 31

Step Action Procedure

1

Re-assemble barrel It is VERY IMPROTANT that calibration be performed

when the product in the barrel is in a 100% liquid state.

There can be no ice in the barrel or on the beater bar.

2

Defrost the barrel Select DFRST on the Barrel Status menu (Figure 8). It is

very important that calibration be performed on a fully

defrosted barrel (outlet temperature must be 41

°F or barrel

must be purged and refilled with new product). Selecting

DFRST while the barrel is off initiates a full defrost cycle.