8 MAINTENANCE AND INSPECTION

8.1 Daily Inspection

115

8

8 MAINTENANCE AND INSPECTION

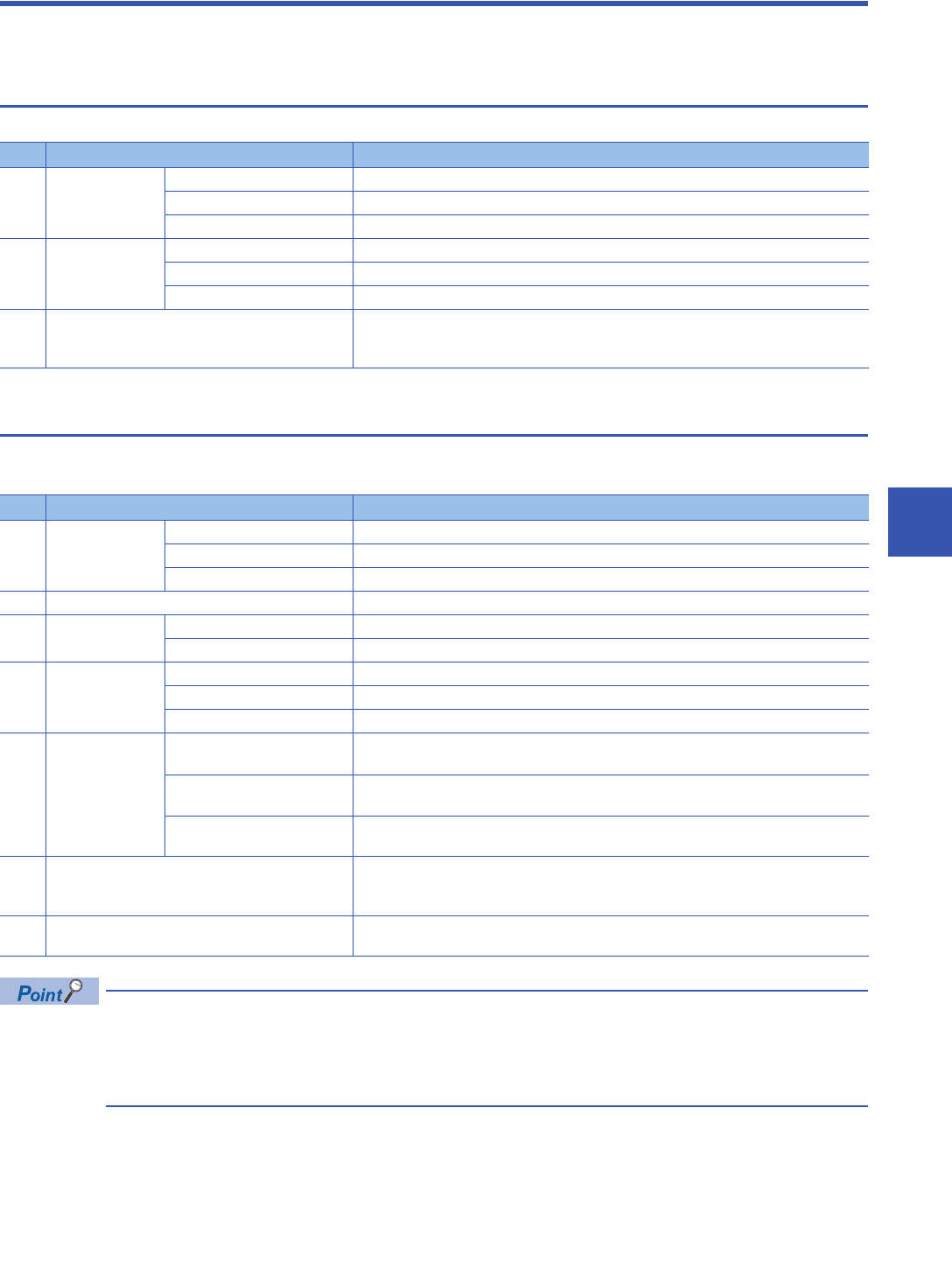

To keep using the PLC in the optimal condition, perform the following inspections daily or periodically.

8.1 Daily Inspection

Perform the following inspections on a daily basis.

8.2 Periodic Inspection

Perform the following inspections once or twice every 6 months to a year.

Also perform the inspections when facilities have been relocated or modified or when wiring has been changed.

The product life of relay contacts varies considerably depending on the load type used. Note that loads

generating reverse electromotive force or rush current may cause poor contact or welding of contacts which

may lead to considerable reduction of the contact product life.

Page 89 Product life of relay output contacts

Item Inspection item Description

1 Installation status

of the module

Looseness of mounting screws Retighten the mounting screws.

Mounting status of the module The module should be securely mounted.

Looseness of cover The cover should not be off.

2 Connection status Looseness of terminal screws Retighten the terminal screws.

Proximity of crimp terminals Check the proximity between crimp terminals and correct the clearance.

Looseness of connectors Connect cable connectors securely.

3 LED status Check that the LED status is normal.

Page 120 Checking with LEDs

User's manuals for each module

Item Inspection item Description

1Ambient

environment

Operating ambient temperature The temperature in the panel should be 0 to 55 (32 to 131).

Operating ambient humidity The humidity in the panel should be 5 to 95%RH.

Working atmosphere Free from corrosive or flammable gas and excessive conductive dust

2 Power supply voltage Voltage within the specified range should be supplied.

3 Installation status Looseness, rattling Retighten mounting screws.

Dirt, foreign matter Wipe away any dirt or foreign matter. Clean the module.

4 Connection status Looseness of terminal screws Retighten the terminal screws.

Proximity of crimp terminals Check the proximity between crimp terminals and correct the clearance.

Looseness of connectors Connect cable connectors securely.

5 Battery BAT LED The BAT LED should be turned off.

When the BAT LED lights up, replace the battery with new one.

Period following the battery

purchase

Replace the battery with new one if 5 years or more have passed since the battery was

purchased.

OFF status of SM51 (SM8005),

SM52 (SM8006)

SM51 (SM8005) and SM52 (SM8006) should be off.

If SM51 (SM8005) and SM52 (SM8006) are on, replace the battery with new one.

6 Module Diagnostics (CPU Diagnostics) The normal status of the system should be checked with the Module Diagnostics (CPU

Diagnostics).

Page 122 Module diagnostics (CPU Diagnostics)

7 Relay contacts Check the product life of relay outputs.

Page 89 Product life of relay output contacts