28

Operat ing Procedures Mod el 5454

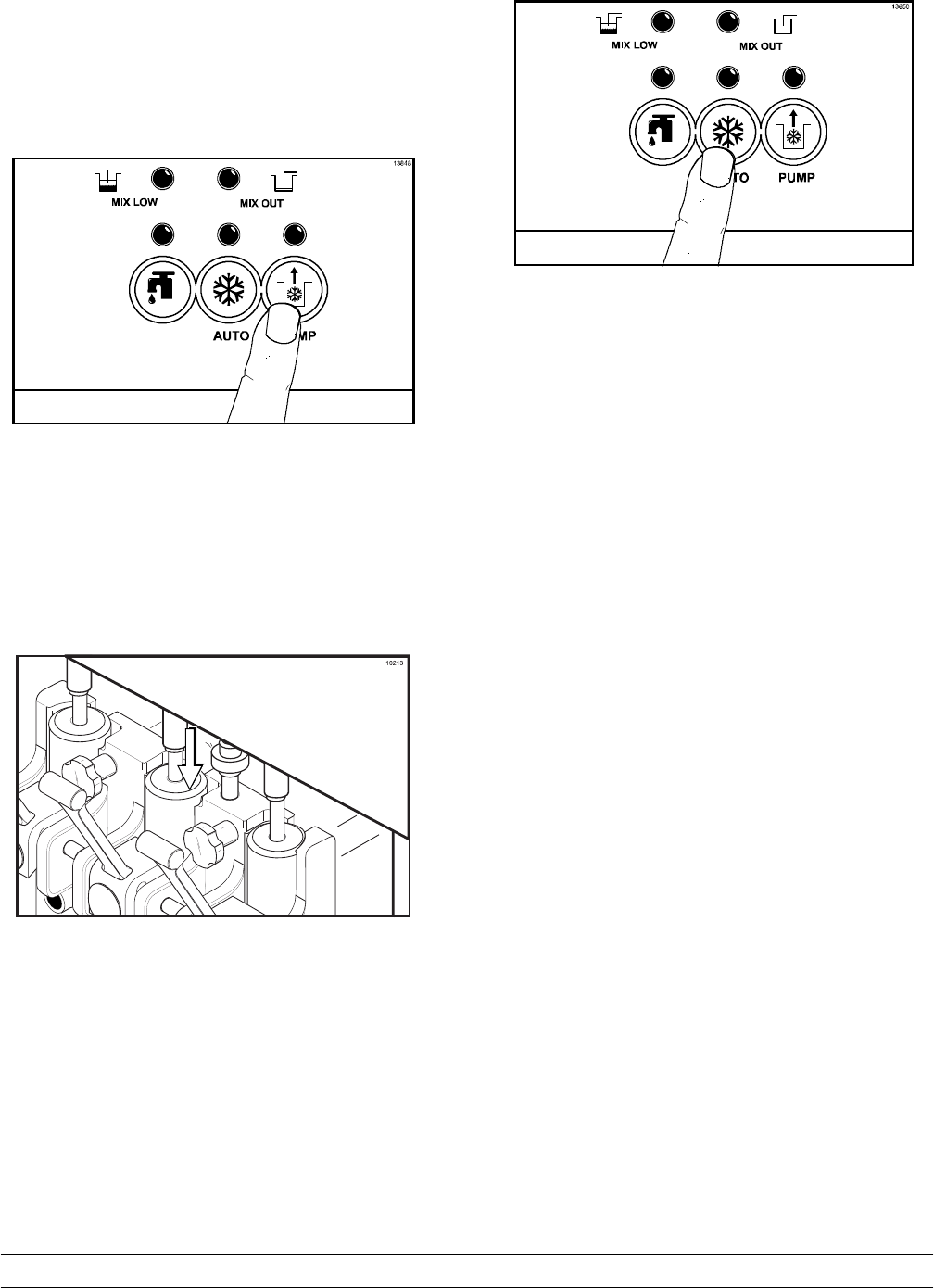

Step 6

When a steady stream of mix is flowing from the bleed

port in the bottom of the freezer door , press the PUMP

keypad to stop operation.

Figure 50

Step 7

Once the stream of mix stops flowing from the bleed

port, push down the prime plug. Rinse the prime plug

hole area with water; then remove the pail and discard

the mix and sanit izer.

Figure 51

Step 8

Press the AUTO keypad. The MIX light will illuminate,

indicating that the mix refrigeration system is

operating. The AUTO light will illuminate, indicating

that the m ain refrigerat ion system is operating. The

PUMP light will illuminate, indicating that the air/mix

pump will operate whenever mix is needed in the

freezing cylinder.

Figure 52

When the unit cycl es off, the product will be at the

correct viscosity.

Note: Keep the mixcabinet door c losed, except when

filling the mix tank and during the cleaning and

sanitizing pr ocedures. Leaving the door open during

mix refr igeration may cause ice in the evaporator and

impair the mix cabinet refr igeration.

Syrup System

T wo main objectives in your opening procedures must

be to:

A. fill the syrup tank s, and

B. calibrate the syrup flow.

These conditions must be checked daily to insure the

high quality shake y ou desir e.

Discard syrup weekly and flush the syrup lines at least

once a week. This will prevent syrup from clogging the

lines and will break the bacteria chain. See page 34 to

sanitize the syrup system.

The syrup tanks can be put in a separate compartment

that c an be placed behind the freezer or to the side.

The air lines and syrup lines are color spiral wrapped.

Be sure to match the color wrapped air and syrup line

to the correct flavor s yrup tank .

Note: To maintain proper calibration, vanilla and

strawberry syrup lines use restrictors at the syrup tank

quick dis connect c onnections. Use only single

streng th syrup that is free of pulp a nd seeds.

Unscrew the quick disconnect fr om the elbow portion

of the syrupline. Make sure the o- ring rest s on t heend

of the quick disconnect fitt ing. Place the restrictor on

top of the o- ring and screw the quick disconnect back

onto the syrup line.