11RLC-PRC006-EN

Application

Considerations

Ice Storage Provides Reduced Electrical

Demand

An ice storage system uses a standard

chiller to make ice at night when utilities

charge less for electricity. The ice

supplements or even replaces

mechanical cooling during the day when

utility rates are at their highest. This

reduced need for cooling results in big

utility cost savings.

Another advantage of ice storage is

standby cooling capacity. If the chiller is

unable to operate, one or two days of ice

may still be available to provide cooling.

In that time the chiller can be running

again before building occupants feel any

loss of comfort.

The Trane Model RTAC chiller is uniquely

suited to low temperature applications

like ice storage because of the ambient

relief experienced at night. This allows

the Model RTAC chiller to produce ice

efficiently, with less stress on the

machine.

Simple and smart control strategies are

another advantage the Model RTAC

chiller offers for ice storage applications.

Trane Tracer

™

building management

systems can actually anticipate how

much ice needs to be made at night and

operate the system accordingly. The

controls are integrated right into the

chiller. Two wires and preprogrammed

software dramatically reduce field

installation cost and complex

programming.

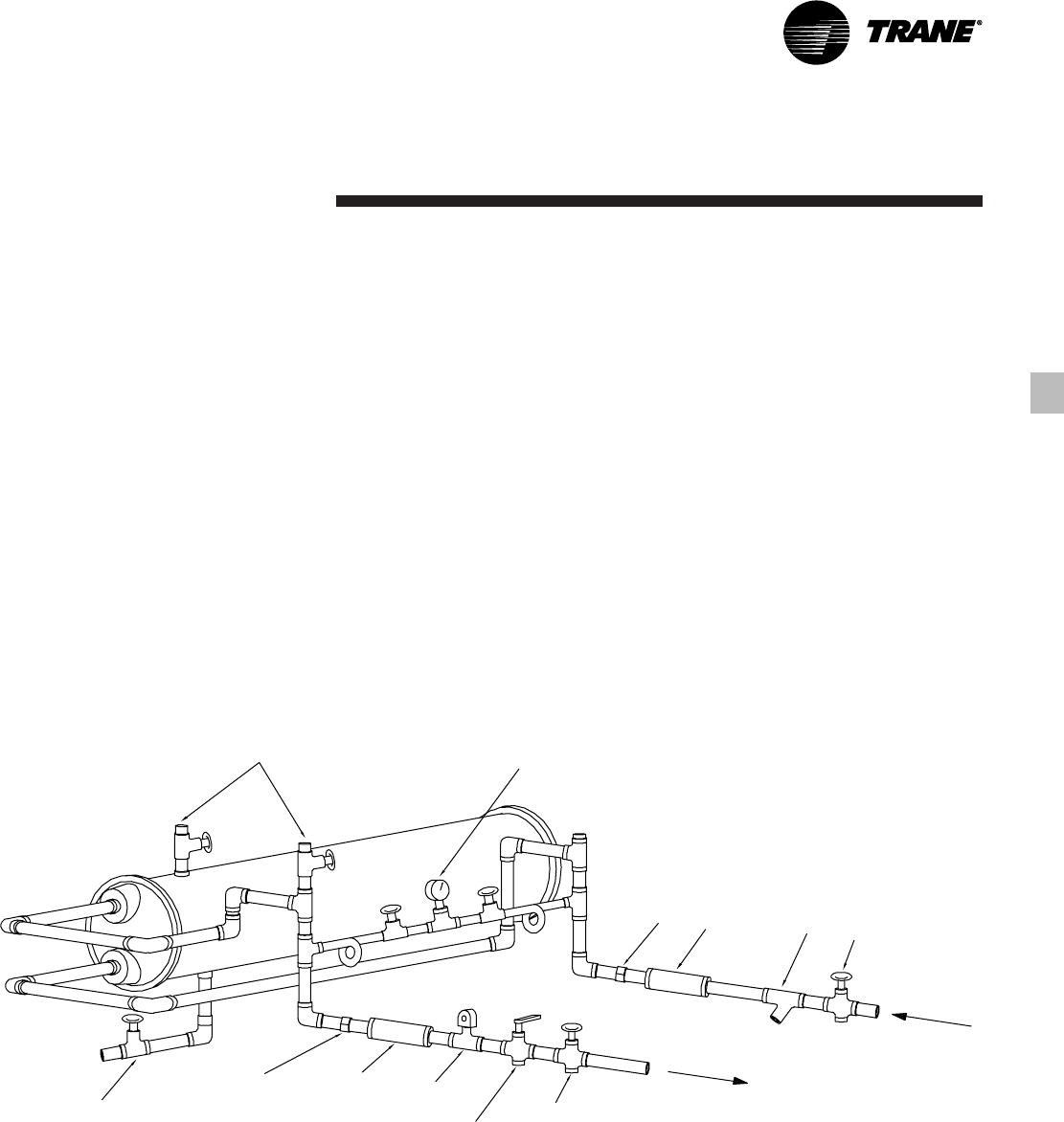

Typical Water Piping

All building water piping must be

flushed prior to making the final

connections to the chiller. To reduce heat

loss and prevent condensation,

insulation should be installed. Expansion

tanks are also usually required so that

chilled water volume changes can be

accommodated. A typical piping

arrangement is shown in Figure 6.

Figure 6 — Water Piping Recommendations

Vents

Valved

Pressure

Gage

Union

Elastomeric

Vibration

Eliminator

Water

Strainer

Gate

Valve

Gate Valve

Balancing Valve

Flow Switch

(Optional)

Elastomeric

Vibration

Eliminator

Union

Drain