9RLC-PRC006-EN

Important

Certain application constraints should be

considered when sizing, selecting and

installing Trane air-cooled Series R

chillers. Unit and system reliability is

often dependent upon proper and

complete compliance with these

considerations. When the application

varies from the guidelines presented, it

should be reviewed with your local

Trane sales engineer.

Unit Sizing

Unit capacities are listed in the

performance data section. Intentionally

over-sizing a unit to assure adequate

capacity is not recommended. Erratic

system operation and excessive

compressor cycling are often a direct

result of an oversized chiller. In addition,

an oversized unit is usually more

expensive to purchase, install, and

operate. If over-sizing is desired,

consider using multiple units.

Water Treatment

Dirt, scale, products of corrosion and

other foreign material will adversely

affect heat transfer between the water

and system components. Foreign matter

in the chilled water system can also

increase pressure drop and

consequently, reduce water flow. Proper

water treatment must be determined

locally, depending on the type of system

and local water characteristics. Neither

salt nor brackish water is recommended

for use in Trane air-cooled Series R

chillers. Use of either will lead to a

shortened life to an indeterminable

degree. The Trane Company encourages

Application

Considerations

the employment of a reputable water

treatment specialist, familiar with local

water conditions, to assist in this

determination and in the establishment

of a proper water treatment program.

Effect Of Altitude On Capacity

Air-cooled Series R chiller capacities

given in the performance data tables are

for use at sea level. At elevations

substantially above sea level, the

decreased air density will reduce

condenser capacity and, therefore, unit

capacity and efficiency.

Ambient Limitations

Trane air-cooled Series R chillers are

designed for year-round operation over

a range of ambient temperatures. The

Model RTAC chiller will operature as

standard in ambient temperatures of 25

to 115°F/-4 to 46°C. With the low

ambient option, these units will operate

down to 0°F/-18°C. If an ambient

temperature as high as 125°F/51°C is the

basis for design, the high ambient option

will permit the chiller to run without

going into a limiting condition. For

installations in areas with large ambient

differences, the wide ambient option will

allow the chiller to perform uninhibited

from 0 to 125°F/-18 to 51°C. For

operation outside these ranges, contact

the local Trane sales office.

Water Flow Limits

The minimum and maximum water flow

rates are given in Tables G-1 and G-2.

Evaporator flow rates below the

tabulated values will result in laminar

flow causing freeze-up problems,

scaling, stratification and poor control.

Flow rates exceeding those listed may

result in excessive tube erosion.

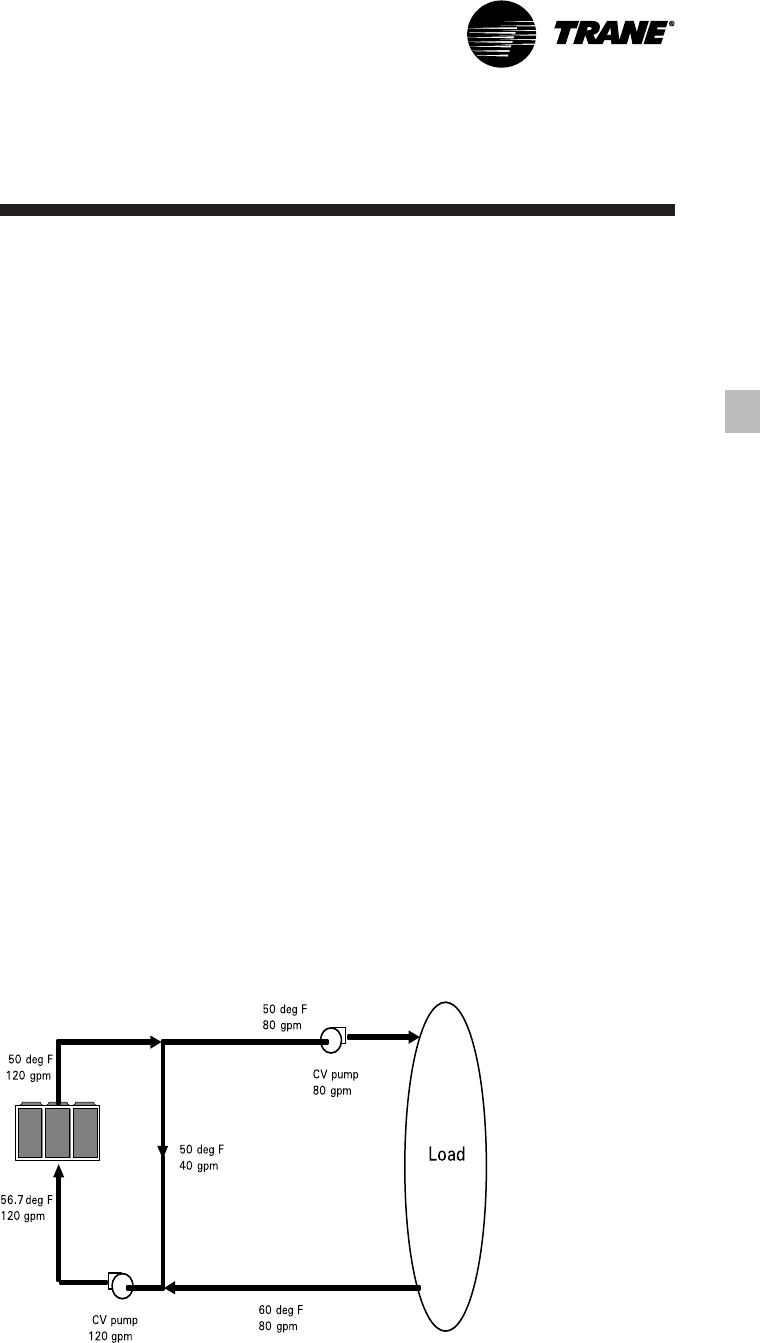

Flow Rates out of Range

Many process cooling jobs require flow

rates that cannot be met with the

minimum and maximum published

values for the Model RTAC evaporator. A

simple piping change can alleviate this

problem. For example: A plastic injection

molding process requires 80 gpm

[5.1 l/s] of 50°F [10°C] water and returns

that water at 60°F [15.6°C]. The selected

chiller can operate at these

temperatures, but has a minimum flow

rate of 120 gpm [7.6 l/s]. The system

layout in Figure 4 can satisfy the process.

Flow Control

Trane requires the chilled water flow

control in conjunction with the Air-

Cooled Series R Chiller to be done by the

chiller. This will allow the chiller to

protect itself in potentially harmful

conditions.

Figure 4 — GPM Out of Range System Layout