RLC-PRC006-EN52

Generic Building Automation

System Controls

Controls

Easy Interface to A Generic Building

Management System

Controlling the air-cooled Series R chiller

with building management systems is

state-of-the-art, yet simple with either the

LonTalk Communications Interface for

Chillers (LCI-C) or Generic Building

Management System Hardwire Points.

Simple Interface with Other Control

Systems

Microcomputer controls afford simple

interface with other control systems,

such as time clocks, building automation

systems, and ice storage systems. This

means you have the flexibility to meet

job requirements while not having to

learn a complicated control system. This

setup has the same standard features as

a stand-alone water chiller, with the

possibility of having additional optional

features.

What are LonTalk, Echelon, and

LonMark?

LonTalk is a communications protocol

developed by the Echelon Corporation.

The LonMark association develops

control profiles using the LonTalk

communication protocol. LonTalk is a

unit level communications protocol,

unlike BACNet used at the system level.

LonTalk Communications

Interface for Chillers (LCI-C)

LonTalk Communications Interface for

Chillers (LCI-C) provides a generic

automation system with the LonMark

chiller profile inputs/outputs. The inputs/

outputs include both mandatory and

optional network variables. Note:

LonMark network variable names are in

parentheses when different from chiller

naming convention.

Chiller Inputs:

• Chiller Enable/Disable

• Chilled Liquid Setpoint (Cool Setpoint)

• Current Limit Setpoint (Capacity Limit

Input)

• Ice Making (Chiller Mode)

Chiller Enable/Disable

Allows for chiller to be started or

stopped depending on if certain

operating conditions are met.

Chilled Liquid Setpoint

Allows for the external setting

independent of the front panel setpoint

to adjust the leaving water temperature

setpoint.

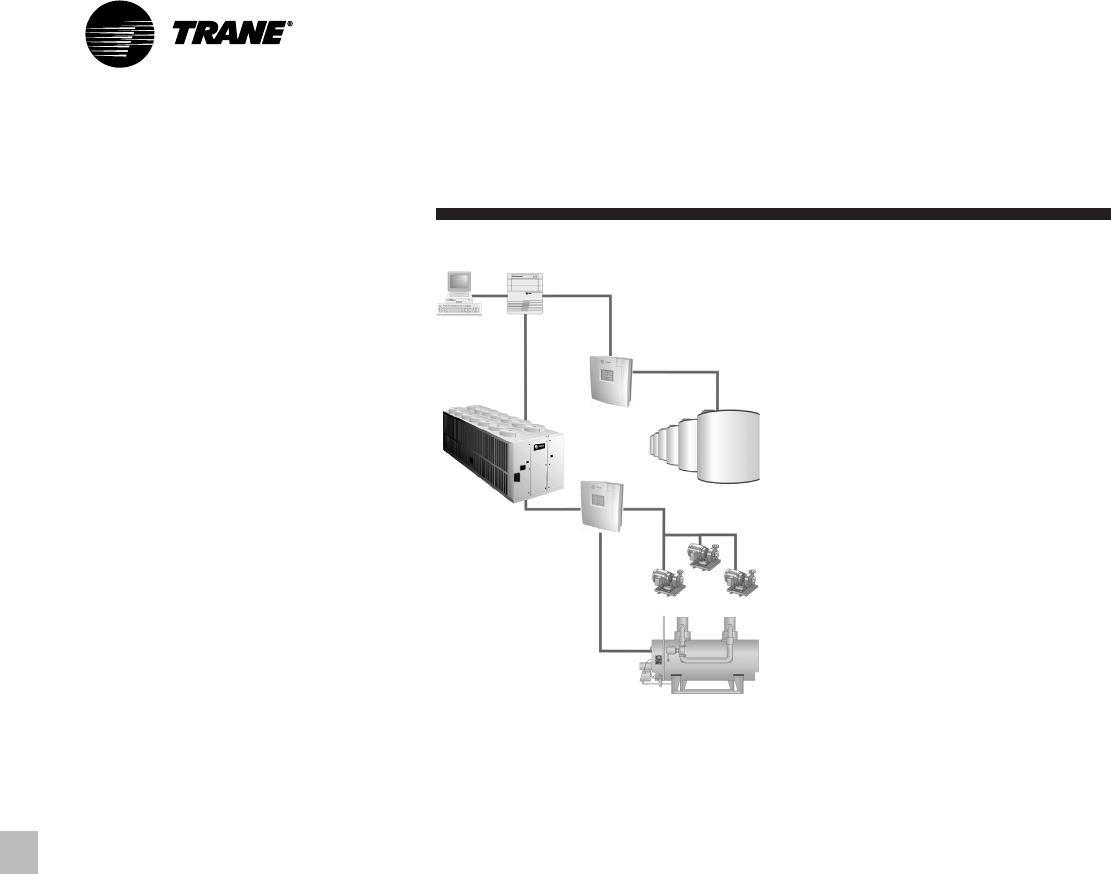

PC Workstation

System Level

Controller

MP581 Programmable

Controller

Air-cooled

Series R

™

Chiller

MP581

Programmable

Controller

Ice Tanks

Boiler

Current Limit Setpoints

Allows for the external setting

independent of the front panel setpoint

to limit the capacity level of the chiller.

Ice Making

Provides interface with ice making

control systems. Please refer to page 54

for more information.

Chiller Outputs:

• On/Off

• Active Setpoint

• Average Percent RLA (Actual Capacity

Level)

• Active Current Limit Setpoint (Capacity

Limit)

• Leaving Chilled Water Temperature

• Entering Chilled Water Temperature

• Alarm Descriptor

• Chiller Status

On/Off

Indicates the current state of the chiller

Active Setpoint

Indicates the current value of the leaving

water temperature setpoint

Average Percent RLA

Provides the current capacity level via

%RLA

Active Current Limit Setpoint

Provides the current capacity level

setpoint via %RLA

Leaving Chilled Water Temperature

Provides the current leaving water

temperature

Entering Chilled Water Temperature

Provides the current entering water

temperature

Alarm Descriptor

Provides alarm messages based on pre-

determined criteria

Chiller Status

Indicates the running modes and states

of the chiller, i.e. Running in alarm mode,

chiller enabled, chiller being locally

controlled, etc…

Generic Building Management

System Hardwire Points

GBAS may be achieved via hardware

input/output as well. The input/outputs

are as follows:

Chiller hardwire inputs include:

• Chiller enable/disable

• Circuit enable/disable

• External chilled water setpoint

• External current limit setpoint

• Ice making enable

External Chilled Water Setpoint

Allows the external setting independent

of the front panel setpoint by one of two

means:

a) 2-10 VDC input, or

b) 4-20 mA input

External Current Limit Setpoint

Allows the external setting independent

of the front panel setpoint by one of two

means:

c) 2-10 VDC input, or

b) 4-20 mA input

Chiller hardwire outputs include:

• Compressor running indication

• Alarm indication (Ckt1/Ckt 2)

• Maximum capacity

• Ice making status

Alarm Indication Contacts

The unit provides three single-pole/

double-throw contact closures to

indicate:

a) Compressor on/off status

b) Compressor running at maximum

capacity

c) Failure has occurred (Ckt 1/Ckt 2)

These contact closures may be used to

trigger jobsite supplied alarm lights or

alarm bells.

Ice Making Control

Provides interface with ice making

control systems.