RLC-PRC006-EN12

Application

Considerations

Short Water Loops

The proper location of the temperature

control sensor is in the supply (outlet)

water connection or pipe. This location

allows the building to act as a buffer and

assures a slowly changing return water

temperature. If there is not a sufficient

volume of water in the system to provide

an adequate buffer, temperature control

can be lost, resulting in erratic system

operation and excessive compressor

cycling. A short water loop has the same

effect as attempting to control from the

building return water. Typically, a two-

minute water loop is sufficient to prevent

problems. Therefore, as a guideline,

ensure the volume of water in the

evaporator loop equals or exceeds two

times the evaporator flow rate. For a

rapidly changing load profile, the

amount of volume should be increased.

To prevent the effect of a short water

loop, the following items should be

given careful consideration: A storage

tank or larger header pipe to increase the

volume of water in the system and,

therefore, reduce the rate of change of

the return water temperature.

Applications Types

• Comfort cooling.

• Industrial process cooling.

• Ice/thermal storage.

• Low temperature process cooling.

Typical Unit Installation

Outdoor HVAC equipment must be

located to minimize noise and vibration

transmission to the occupied spaces of

the building structure it serves. If the

equipment must be located in close

proximity to a building, it could be

placed next to an unoccupied space such

as a storage room, mechanical room,

etc. It is not recommended to locate the

equipment near occupied, sound

sensitive areas of the building or near

windows. Locating the equipment away

from structures will also prevent sound

reflection, which can increase levels at

property lines, or other sensitive points.

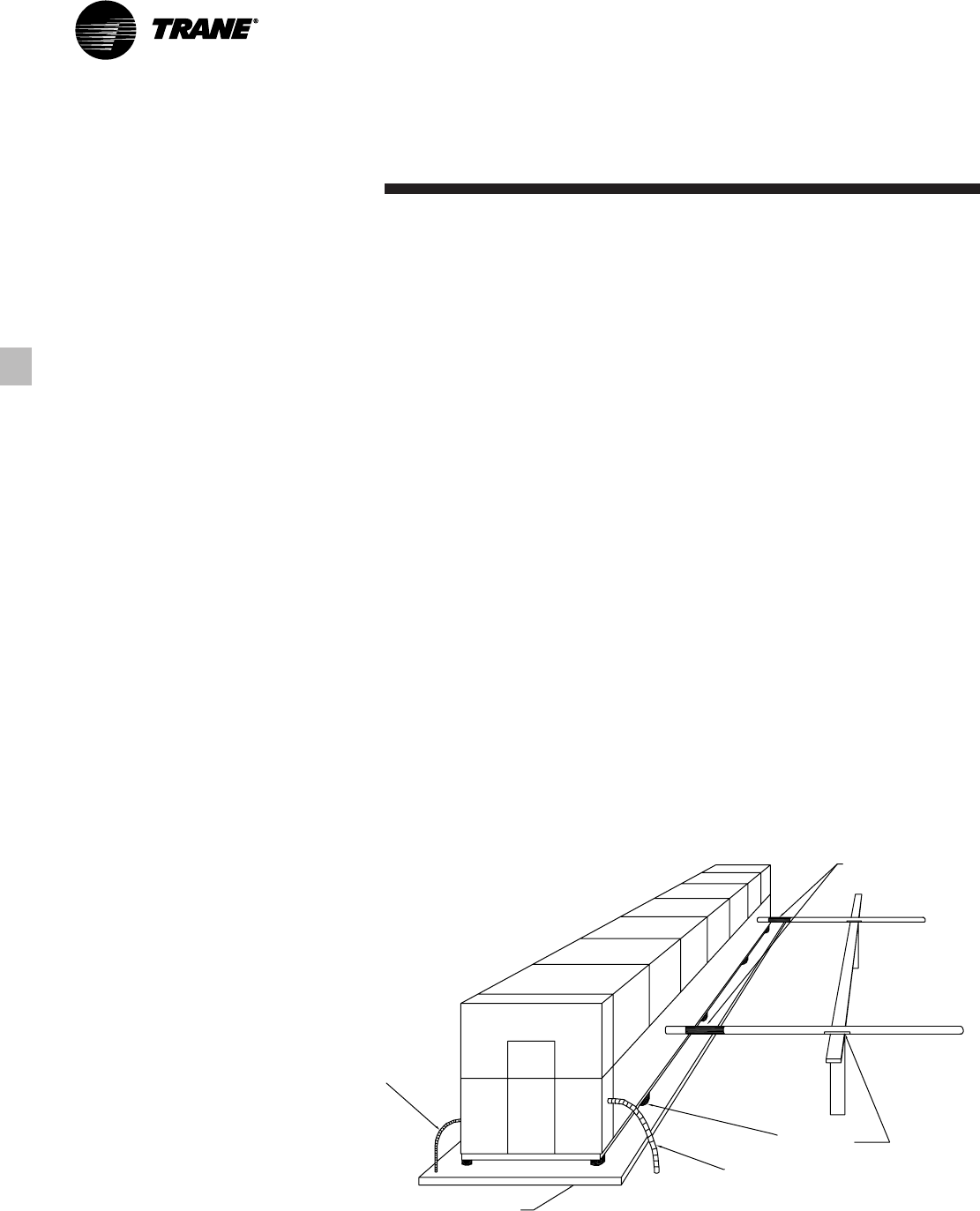

When physically isolating the unit from

structures, it is a good idea to not use

rigid supports, and to eliminate any

metal-to-metal or hard material contact,

when possible. This includes replacing

spring or metal weave isolation with

elastomeric isolators. Figure 7 illustrates

isolation recommendations for the

RTAC.

Elastomeric

Vibration

Eliminators

Avoid using the

chiller to support

chiller water

piping.

Neoprene

Isolators

Flex Conduit

Power Wiring

Concrete Base

Flex Conduit

Control Power

Figure 7 — Unit Isolation Recommendations