7RLC-PRC006-EN

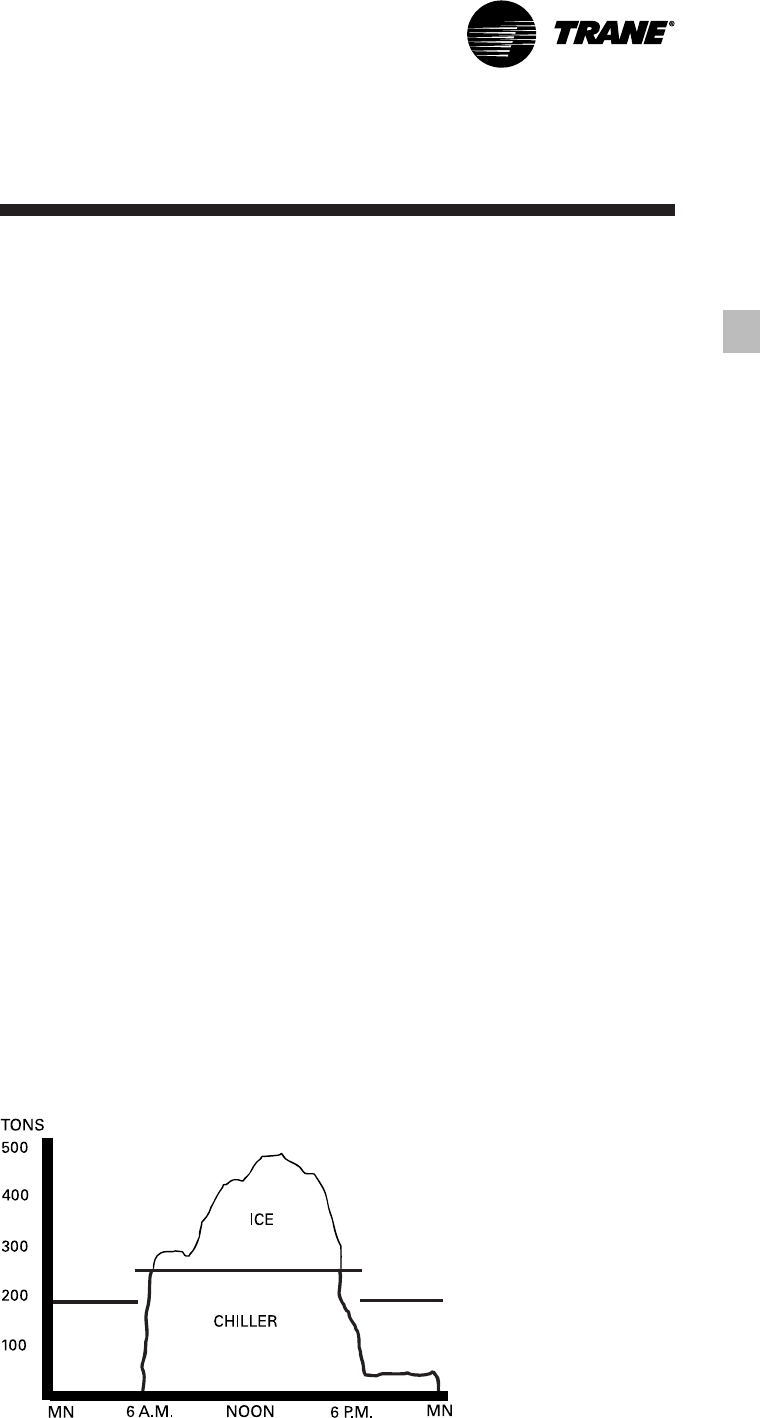

Figure 3 — Ice Storage Demand Cost Savings

Superior Control with Tracer

™

Chiller Controllers

The Adaptive Control

™

microprocessor

system enhances the air-cooled Series R

chiller by providing the very latest chiller

control technology. With the Adaptive

Control microprocessor, unnecessary

service calls and unhappy tenants are

avoided. The unit is designed not to trip

or unnecessarily shut down. Only when

the Tracer

™

chiller controllers have

exhausted all possible corrective actions

and the unit is still violating an operating

limit will the chiller shut down. Controls

on other equipment typically shut down

the chiller, usually just when it is needed

the most.

For example:

A typical five-year-old chiller with dirty

coils might trip-out on high pressure

cutout on a 100°F (38°C) day in August. A

hot day is just when comfort cooling is

needed the most. In contrast, the air-

cooled Series R chiller with an Adaptive

Control microprocessor will stage fans

on, modulate electronic expansion valve,

and modulate slide valve position as it

approaches a high pressure cutout,

thereby keeping the chiller on-line when

you need it the most.

System Options — Ice Storage

Trane air-cooled Series R Chillers are

well suited for ice production. An air-

cooled machine typically switches to ice

production at night. Two things happen

under this assumption. First, the leaving

brine temperature from the evaporator is

lowered to around 22 to 24°F

(-5.5 to –4.4°C). Second, the ambient

temperature has typically dropped about

15 to 20°F (8.3 to 11°C) from the peak

daytime ambient. This effectively places

a lift on the compressors that is similar

to daytime running conditions. The

chiller can operate in lower ambient at

night and successfully produce ice to

supplement the next day’s cooling

demands.

The Model RTAC produces ice by

supplying ice storage tanks with a

constant supply of glycol solution. Air-

cooled chillers selected for these lower

leaving fluid temperatures are also

selected for efficient production of

chilled fluid at nominal comfort cooling

conditions. The ability of Trane chillers to

serve “double duty” in ice production

and comfort cooling greatly reduces the

capital cost of ice storage systems.

When cooling is required, ice chilled

glycol is pumped from the ice storage

tanks directly to the cooling coils. No

expensive heat exchanger is required.

The glycol loop is a sealed system,

eliminating expensive annual chemical

treatment costs. The air-cooled chiller is

also available for comfort cooling duty at

nominal cooling conditions and

efficiencies. The modular concept of

glycol ice storage systems and the

proven simplicity of Trane Tracer

controllers allow the successful blend of

reliability and energy saving

performance in any ice storage

application.

The ice storage system is operated in six

different modes: each optimized for the

utility cost of the hour.

1. Provide comfort cooling with chiller

2. Provide comfort cooling with ice

3. Provide comfort cooling with ice and

chiller

4. Freeze ice storage

5. Freeze ice storage when comfort

cooling is required

6. Off

Tracer optimization software controls

operation of the required equipment and

accessories to easily transition from one

mode of operation to another. For

example:

Even with ice storage systems there are

numerous hours when ice is neither

produced or consumed, but saved. In

this mode the chiller is the sole source of

cooling. For example, to cool the

building after all ice is produced but

before high electrical demand charges

take effect, Tracer sets the air-cooled

chiller leaving fluid setpoint to its most

efficient setting and starts the chiller,

chiller pump, and load pump.

When electrical demand is high, the ice

pump is started and the chiller is either

demand limited or shut down

completely. Tracer controls have the

intelligence to optimally balance the

contribution of ice and chiller in meeting

the cooling load.

The capacity of the chiller plant is

extended by operating the chiller and ice

in tandem. Tracer rations the ice,

augmenting chiller capacity while

reducing cooling costs. When ice is

produced, Tracer will lower the air-

cooled chiller leaving fluid setpoint and

start the chiller, ice and chiller pumps,

and other accessories. Any incidental

loads that persist while producing ice

can be addressed by starting the load

pump and drawing spent cooling fluid

from the ice storage tanks.

For specific information on ice storage

applications, contact your local Trane

sales office.

Features and

Benefits