5RLC-PRC006-EN

Excellent Reliability…

A buildings environment is expected to

be comfortable. When it is, no one says

a word. If it’s not… that’s a different

story. The same is true with chillers. No

one ever talks about chillers, yet alone

compressors, until they fail, and tenants

are uncomfortable and productivity is

lost. Trane’s helical rotary compressors

have a first year reliability rate of over

99%, which means our chillers stay

running when you need them.

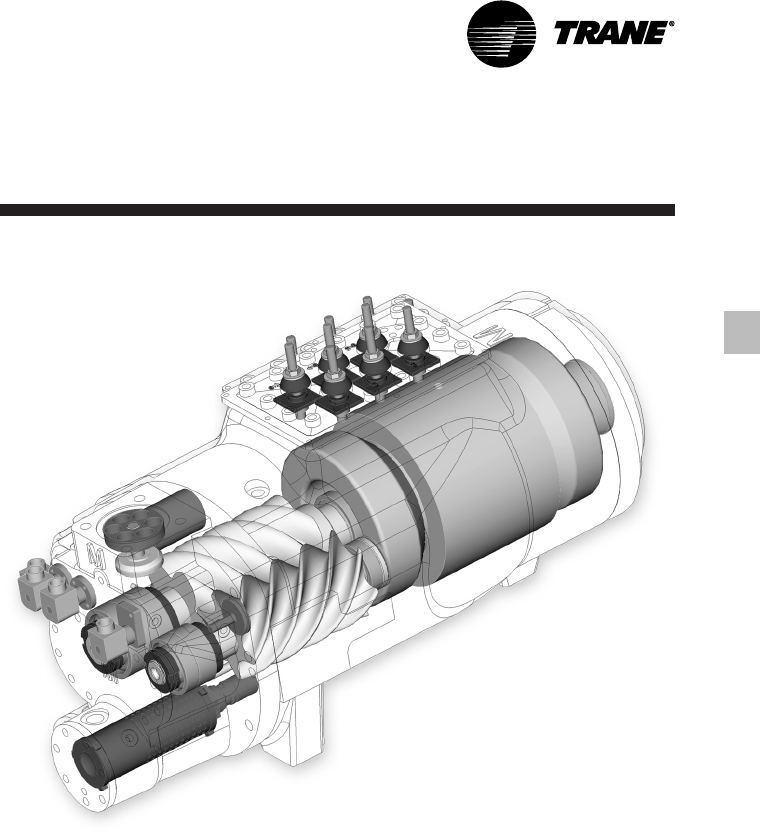

Fewer moving parts. Trane’s helical

rotary compressors have only two major

rotating parts: the male and female rotor.

A reciprocating compressor can have

more than 15 times that number of

critical parts. Multiples of pistons, valves,

crankshafts, and connecting rods in a

reciprocating unit all represent different

failure paths for the compressor. In fact,

reciprocating compressors can easily

have a failure rate four times of a helical

rotor. Combine that with two to three

reciprocating compressors for each

helical rotary compressor on chillers of

equal tonnage, and statistics tell you it’s

a matter of time before you lose a

reciprocating compressor.

Robust components. Helical rotary

compressors are precisely machined

using state of the art processes from

solid metal bar stock. Tolerances are

maintained within a micron or less than

a tenth of the diameter of a human hair.

The resulting compressor is a robust yet

highly sophisticated assembly capable of

ingesting liquid refrigerant without risk

of damage. Contrast this to a

reciprocating compressor, which can be

destroyed by a single slug of liquid.

Condenser coils. Trane’s condenser

coils are manufactured with the same

philosophy as the compressors; they’re

built to last. Even though manufacturing

processes have allowed thinner and

thinner materials in their assembly, with

obvious material and manufacturing

savings, Trane’s coil material did not

change with the RTAC generation of air

cooled chillers. Substantial condenser

fins, that do not require additional

coating in non-corrosive environments,

contribute to the highest reliability

standards for air-cooled chillers in the

industry.

Features and

Benefits

Figure 2 — Cutaway of a compressor