© 1998 Maytag Corporation

16008373-01 SECTION 2. ELECTRICAL COMPONENTS & TESTING

2-12

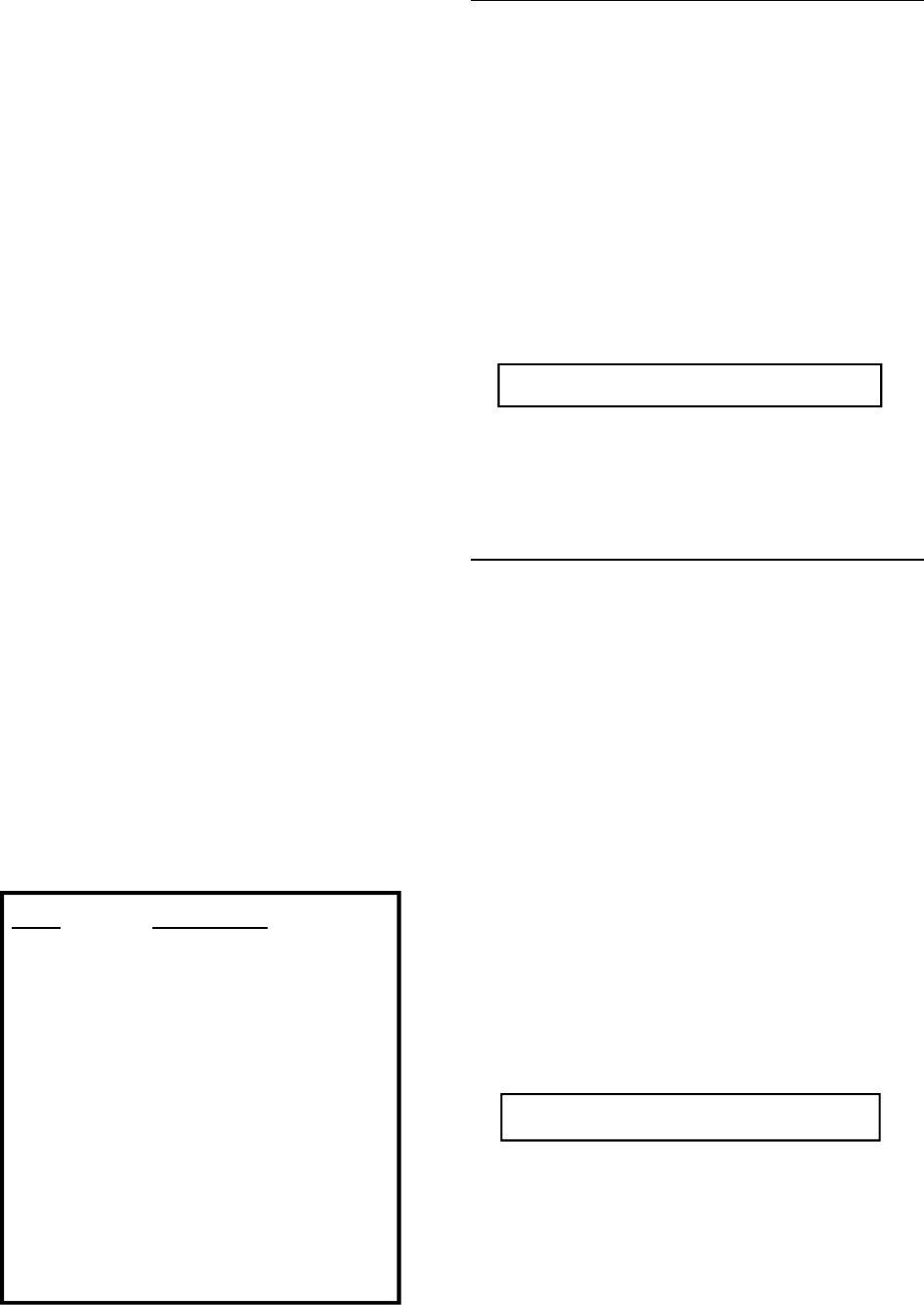

RPM FUNCTION

47 ...........................Tumble

47-85 .......................Distribution

90-250.....................Accelerate Through

Critical

250-499..................Accelerate Through

Critical

500-575..................High Speed Acceleration

- WILL DROP TO 450 RPM

600-675..................High Speed Acceleration

- WILL DROP TO 555 RPM

>675.......................High Speed Acceleration

- WILL DROP TO 650 RPM

750-800.............TOP SPIN SPEED

Figure 2-12

Strut Displacement Switch

The strut displacement switch is clipped to the

top of the left rear strut. The switch senses

the outer tub bottoming out on the strut as

the machine accelerates above 90 rpm. This

is caused by the twisting motion of the outer

tub. This additional switch is required because

the twisting motion may not trip the outer tub

displacement switch. The primary cause for

activation would be an unbalance at the front

and rear of the spinner on opposite sides.

The strut displacement switch is wired in se-

ries with the tub displacement switch and

causes the same type of redistribution.

Testing the Strut Displacement Switch:

1. Disconnect power to the unit.

2. Place ohm meter leads across the two ter-

minals of the switch. Depress the button

on the switch. If the contacts close, the

switch is good. If not, replace the switch.

Tub Displacement Switch

The tub displacement switch is located on the

upper right hand side of the outer tub, below

the top concrete weight, between the outer

tub and the cabinet. The switch senses the

outer tub touching the cabinet side as the

machine passes through critical. When this

switch is tripped, the machine stops and re-

distributes the load.

Testing the Tub Displacement Switch:

1. Disconnect power to the unit.

2. Place ohm meter leads across the two ter-

minals of the switch. Depress the button

on the switch. If the contacts open, the

switch is good. If not, replace the switch.

Whenever a displacement switch is tripped,

the machine stops and redistributes the

clothes load. This involves a three (3) second

pause, followed by a five (5) second reverse

tumble (47-49 rpm) to redistribute the clothes

load. The washer will pause again for three

(3) seconds, then start the distribution profile

again. To redistribute the load, the machine

tumbles the load (50-90 rpm) and again at-

tempts to pass through critical (about 150

rpm). The machine will try to redistribute

twice as the washer attempts to spin at 800

rpm.

Once the load is properly redistributed and

the speed reaches above 500 rpm, the inertial

switch and cabinet vibration sensor are used.

If the inertial switch or sensor is activated, the

washer will drop in spin speed. This is based

upon the speed at which switch activation

takes place. See Figure 2-12 outlining the spin

speed categories and the corresponding re-

duced speeds. If the switches are not acti-

vated, the final spin speed will reach a maxi-

mum of 850 rpm and then drop to find the

optimum performance level, based upon

readings taken by the cabinet vibration sen-

sor. Consumers may be confused by the up-

and-down cycling of the motor. However, the

machine is searching for the optimal speed

performance.