YORK INTERNATIONAL

134

FORM 160.55-O1 (604)

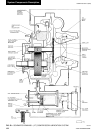

System Components De scrip tion

Victaulic grooves are welded to the water boxes. These

nozzle connections are suit able for Victaulic cou plings,

weld ing or ß anges (300 PSI has ß ang es). 1/2" cou pling

and separable well are lo cat ed in the entering and leav ing

chilled liquid nozzles for tem per a ture sensing el e ments.

Plugged 1/2" or 3/4" drain and vent connections are

pro vid ed in each water box.

COOLER - The cooler is a hor i zon tal, ß ooded, shell-

and-tube type, with a dis tri bu tion system consisting

of a distributor trough to give uniform distribution

through out the shell length and a perforated distributor

plate, lo cat ed under the entire tube bundle, to equally

dis trib ute re frig er ant. Intermediate steel tube supports

are spaced at intervals of less than four feet. High ly ef-

Þ cient, alu mi num mesh eliminators are lo cat ed above

the tube bun dle to prevent liquid refrigerant carryover

into the compressor.

A liquid level sight glass is con ve nient ly located on the

side of the cooler to aid in de ter min ing proper re frig -

er ant charge.

CONDENSER - The con dens er is a hor i zon tal, shell-

and-tube type, with a dis charge gas bafß e to prevent di-

rect high ve loc i ty im pinge ment on the tubes. This baf ß e

is also used to dis trib ute the refrigerant gas ß ow prop er ly

for most ef Þ cient heat transfer. A purge con nec tion is

located in the con dens er for ef Þ cient elim i na tion of

noncondensibles. Intermediate steel tube sup ports are

spaced at in ter vals of less than four feet.

REFRIGERANT FLOW CON TROL - The ß ow con-

trol chamber is welded to the bottom of the con dens er to

allow complete drain age of liquid refrigerant from the

condenser. The chamber con tains a single Þ xed-oriÞ ce

ß ow control with no moving parts.

BURSTING DISC - A 2" or 3" frangible carbon burst-

ing disc relief device is located in the compressor suc-

tion line.

SOLID STATE STARTER (OP TION AL)

The Solid State Starter is a re duced-voltage liquid cooled

starter that controls and maintains a constant current

ß ow to the motor during start-up. The starter is mount ed

on the chiller. The power wiring from the start er to the

mo tor and from the starter control trans form er to the

Control Center is fac to ry wired and test ed. Available

for 200-600V-3Ph-60/50 Hz power; 2 or 3 barrel lug

connections per phase are provided on the starter. The

starter en clo sure is NEMA Type1 and is provided with

a hinged door with lock and key.

VARIABLE SPEED DRIVE (OPTIONAL)

A 460V-3ph-60/50 Hz Variable Speed Drive can be fac-

to ry pack aged with the chiller. It is de signed to vary the

compressor motor speed and prerotation vane position

by con trol ling the fre quen cy and voltage of the elec tri cal

pow er to the motor. Op er a tion al information is con tained

in Form 160.00-O1. The con trol log ic au to mat i cal ly

ad justs mo tor speed and com pres sor prerotation vane

po si tion for max i mum part load efÞ ciency by an a lyz ing

in for ma tion fed to it by sen sors located through out the

chiller.