FORM 160.55-O1 (604)

147

YORK INTERNATIONAL

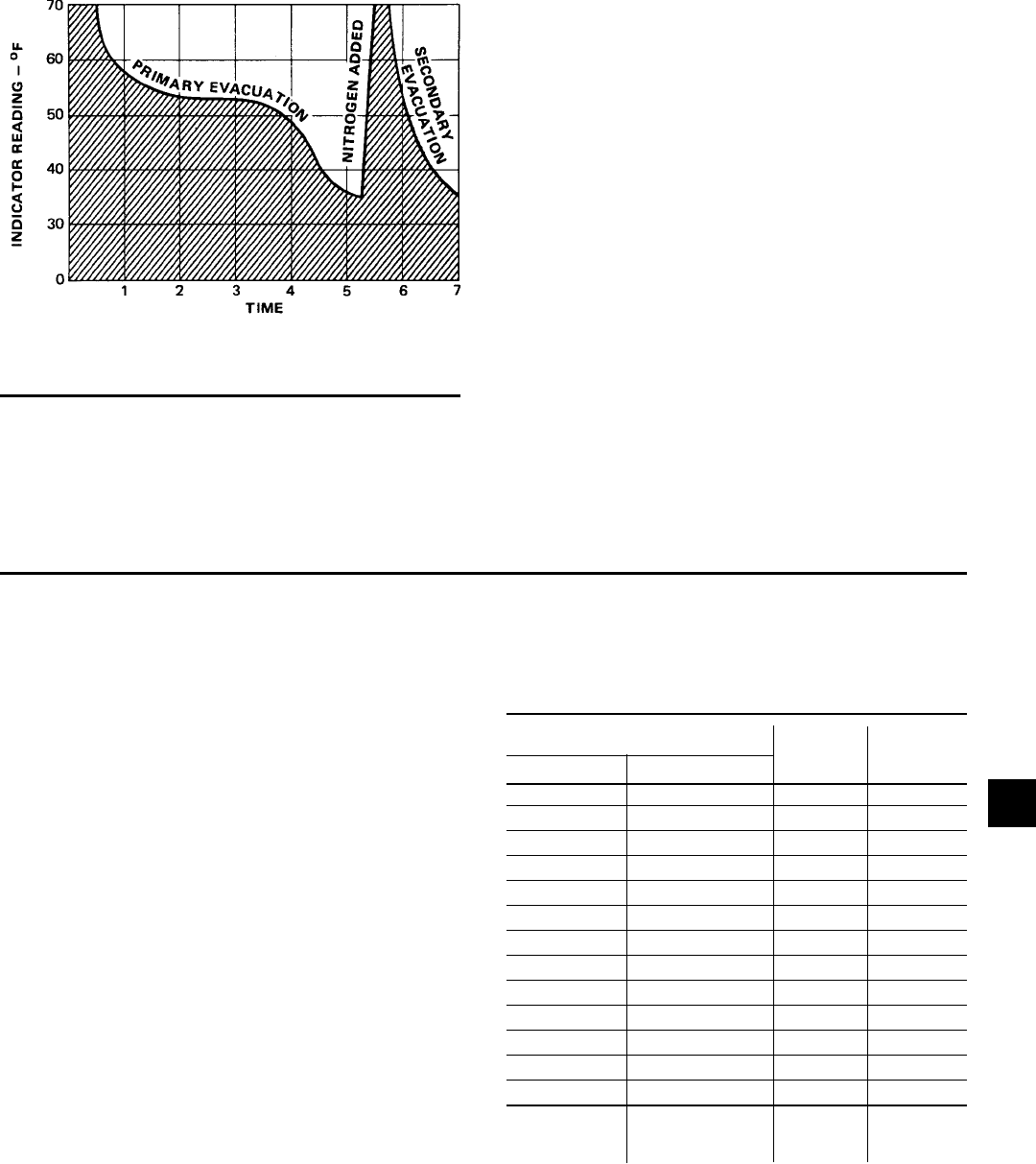

FIG. 64 – SATURATION CURVE

LD00474

SHELL CODES

COOLER COMPRESSOR

G0, G1, G3 B 890 900

G0, G1, G3 C 890 900

H1, H3 − 970 975

J1, J3 − 1130 1125

K1, K3 − 1270 1275

G0, G1, G3 E 890 900

H1, H3 − 970 975

J1, J3 − 1130 1125

K1, K3 − 1270 1275

L1, L3 − 1390 1400

K4, K6 F 1390 1400

K7, K9 − 1530 1550

L4, L6 − 1590 1600

FACTORY

CHARGE SHIPPED

LBS.

When this point is reached, practically all of the air has

been evacuated from the system, but there is still a small

amount of moisture left. In order to provide a medium

for carrying this residual moisture to theVacuum pump,

nitrogen should be in tro duced into the system to bring

REFRIGERANT CHARGING

it to at mo spher ic pressure and the indicator tem per a ture

will re turn to approximately am bi ent tem per a ture. Close

off the system again, and start the second evac u a tion.

The relatively small amount of moisture left will be car-

ried out through theVacuum pump and the tem per a ture or

pressure shown by the indicator should drop uni form ly

until it reaches a tem per a ture of 35°F or a pres sure of

5mm Hg.

When theVacuum indicator registers this tempera-

ture or pres sure it is a positive sign that the system is

evac u at ed and de hy drat ed to the recommended limit.

If this level can not be reached, it is evident that there

is a leak somewhere in the system. Any leaks must be

cor rect ed before the in di ca tor can be pulled down to

35°F or 5mm Hg. in the primary evac u a tion. During

the pri ma ry pull down keep a careful watch on the wet

bulb indicator tem per a ture, and do not let it fall below

35°F. If the tem per a ture is allowed to fall to 32°F the

water in the test tube will freeze, and the result will be

a faulty tem per a ture reading.

To avoid the possibility of freezing the liquid within the

cooler tubes when charg ing an evacuated system, only

refrigerant vapor from the top of the drum or cyl in der

must be ad mit ted to the system until the system pres sure

is raised above the point corresponding to the freez ing

point of the cooler liquid. For water, the pres sure cor-

re spond ing to the freez ing point is 20.4 in Hg.Vacuum

for R-123 (at sea level).

While charg ing, every pre cau tion must be taken to

pre vent mois ture laden air from entering the sys tem.

Make up a suit able charging con nec tion from new cop-

per tubing to Þ t be tween the sys tem charging valve

and the Þ tting on the charging drum. This connection

should be as short as possible but long enough to per mit

suf Þ cient ß ex i bil i ty for chang ing drums. The charg ing

con nec tion should be purged each time a full con tain er

of re frig er ant is con nect ed and changing con tain ers

should be done as quickly as possible to min i mize the

loss of re frig er ant.

Refrigerant may be fur nished in drums con tain ing ei ther

100, 200 or 650 lbs. of re frig er ant. These drums are not

re turn able and they should be stored for future use if

it should ever become nec es sary to re move re frig er ant

from the system.

TABLE 4 – REFRIGERANT CHARGE

8