36

Model PH61Operating Procedures

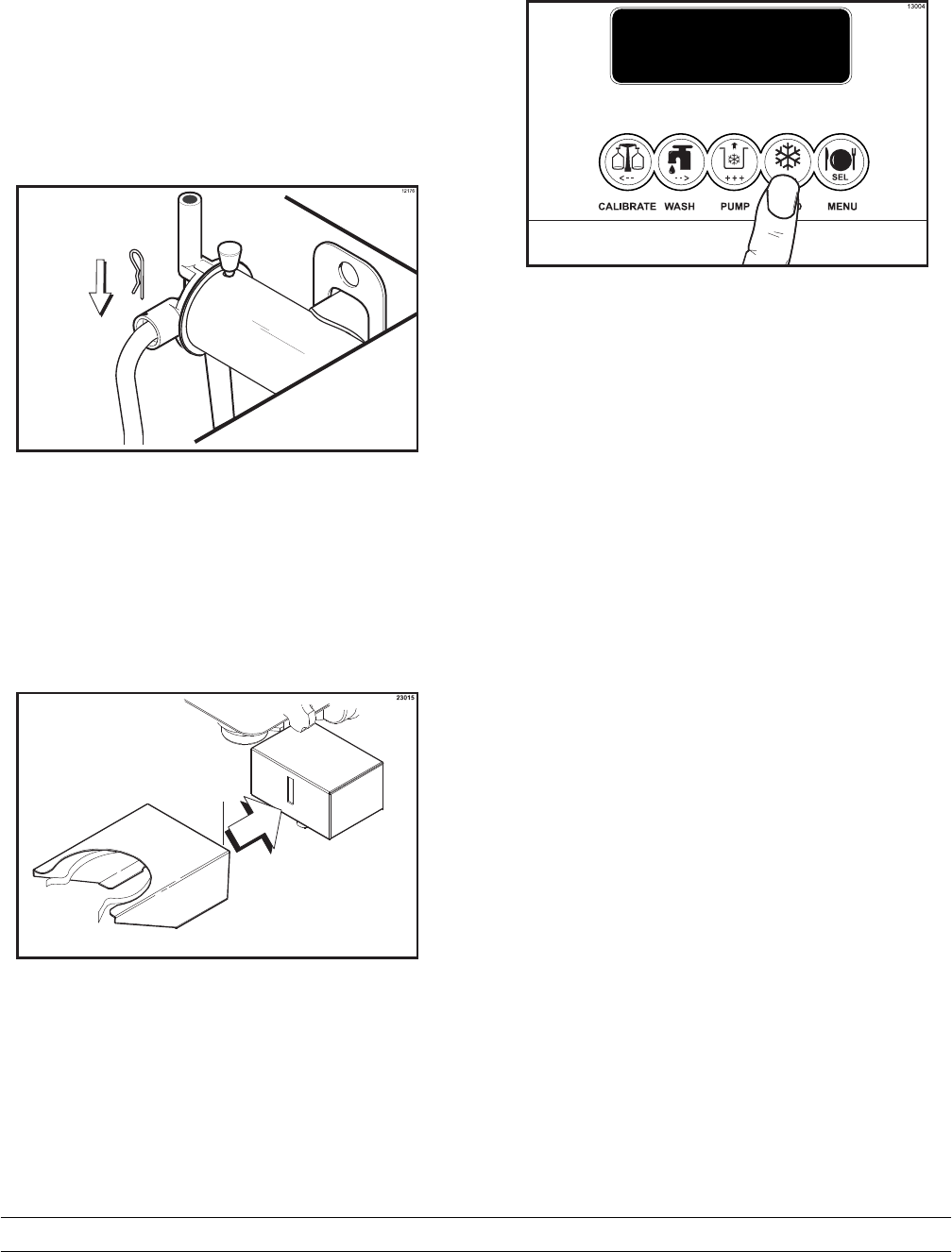

Step 2

When mix stops bubbling down into the freezing

cylinder, remove the cotter pin from the outlet fitting

of the mix pump. Remove the mix feed tube. Insert

the outlet end of the mix feed tube into the mix inlet

hole in the mix hopper. Place the inlet end of the mix

feed tube into the outlet fitting of the mix pump.

Secure with the cotter pin. (See Figure 44.)

Figure 44

Step 3

Install the shake cup holder. (See Figure 45.)

Figure 45

Step 4

Press the AUTO key. (See Figure 46.)

Figure 46

Step 5

Fill the hopper with fresh mix and place the mix

hopper cover in position.

Use only FRESH mix when priming the freezer.

IMPORTANT: When drawing product, allow the

draw handle to close automatically. Manually

closing the draw handle will damage the syrup

valve and cause serious syrup flavor carryover.

Daily Closing Procedures

This procedure must be done at the close of

business.

The function of the Heat Treatment Cycle is to destroy

bacteria by raising the temperature of the mix in the

freezing cylinder and the hopper to a specified

temperature for a specified period of time, and then

bringing the temperature back down low enough to

retard spoilage.

The Heat Treatment Cycle will start at the time

designated in the Auto Heat Time.

IMPORTANT: The level of mix in the hoppers

must be high enough to cover the agitator

paddles.

Note: If the CLEAN MANUALLY light is flashing, do

not add mix. The machine must be disassembled

and brush cleaned within 24 hours.