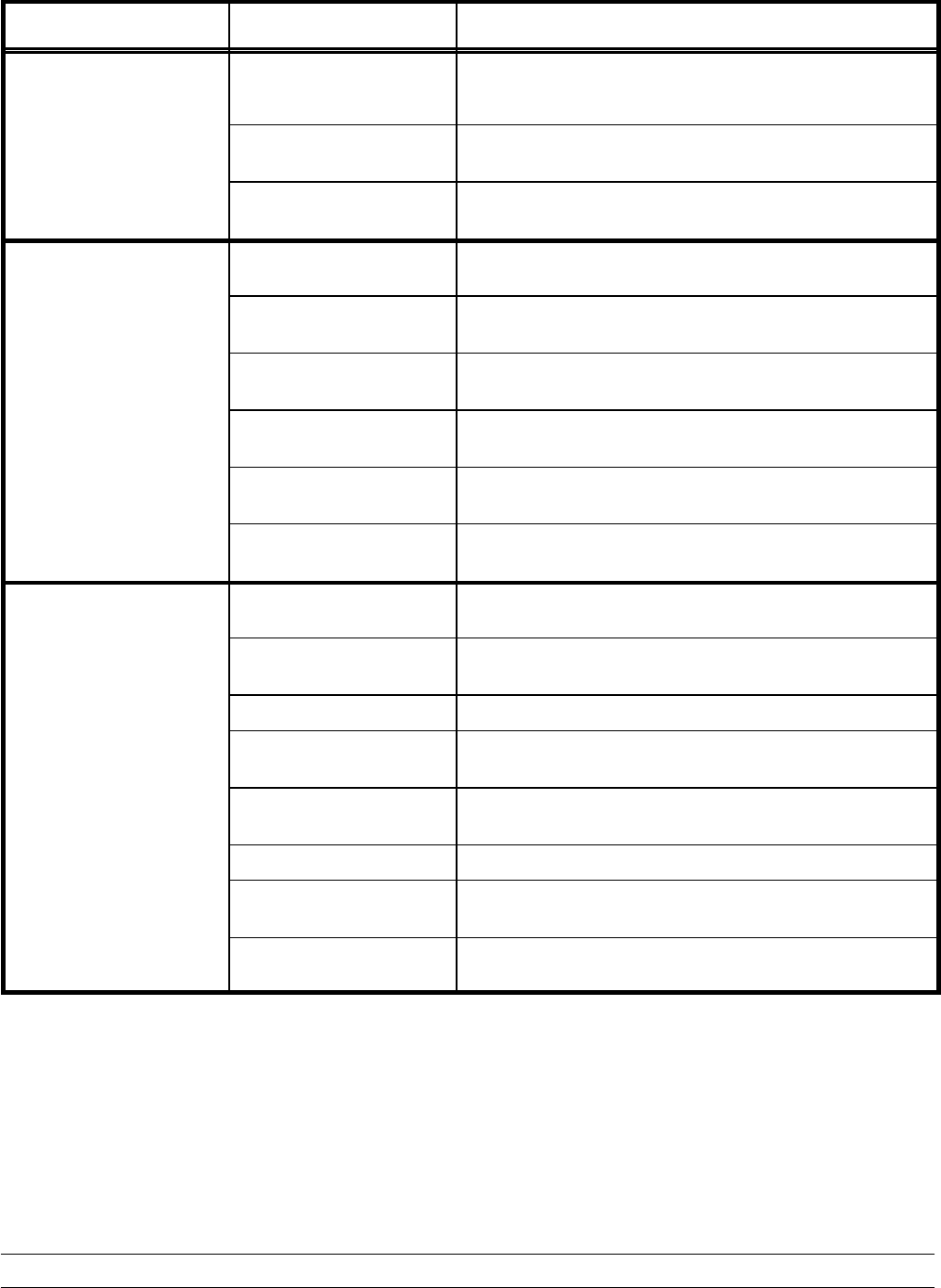

54

Model PH61Troubleshooting Guide

Problem Corrective ActionProbable Cause

No product is being

dispensed. (Cont'd.)

Air/mix pump is

incorrectly assembled or

improperly lubricated.

Follow assembly procedures carefully.

The mix pump ball crank

is broken.

Call service technician.

The pump motor is not

activated.

Push the reset button. The draw valve must be fully

opened to activate the pump motor.

The product is too thick. Not enough syrup - 1 fl.

oz. (30 ml.) in 5 seconds.

Calibrate the syrups. Check that the syrup tanks have

an adequate syrup supply.

Insufficient mix in the

freezing cylinder.

Check the air/mix pump assembly.

Improper priming

procedures.

Drain the freezing cylinder and re-prime the machine.

Air/mix pump incorrectly

assembled.

Follow assembly procedures carefully.

The viscosity control is

set too cold.

Call service technician.

Freeze-up in mix inlet

hole.

Call service technician.

Product is too soft. Too much syrup - 1 fl. oz.

(30 ml.) in 5 seconds.

Calibrate syrups.

Outdrawing capacity of

freezing cylinder.

Continuous draw rate is approximately one 16 oz. (473

ml.) shake by volume every 15-20 seconds.

Inadequate air space. Minimum of 6” (152 mm) air space around all sides.

Dirty condenser or air

filters on air cooled units.

Clean regularly.

Inadequate water supply

on water cooled units.

Check the water supply. Check the water lines for leaks

or kinks.

Bad scraper blades. Replace the scraper blades.

The viscosity control is

set too warm.

Call service technician.

Air passage is blocked in

the pump.

Brush clean the pump components and reassemble.