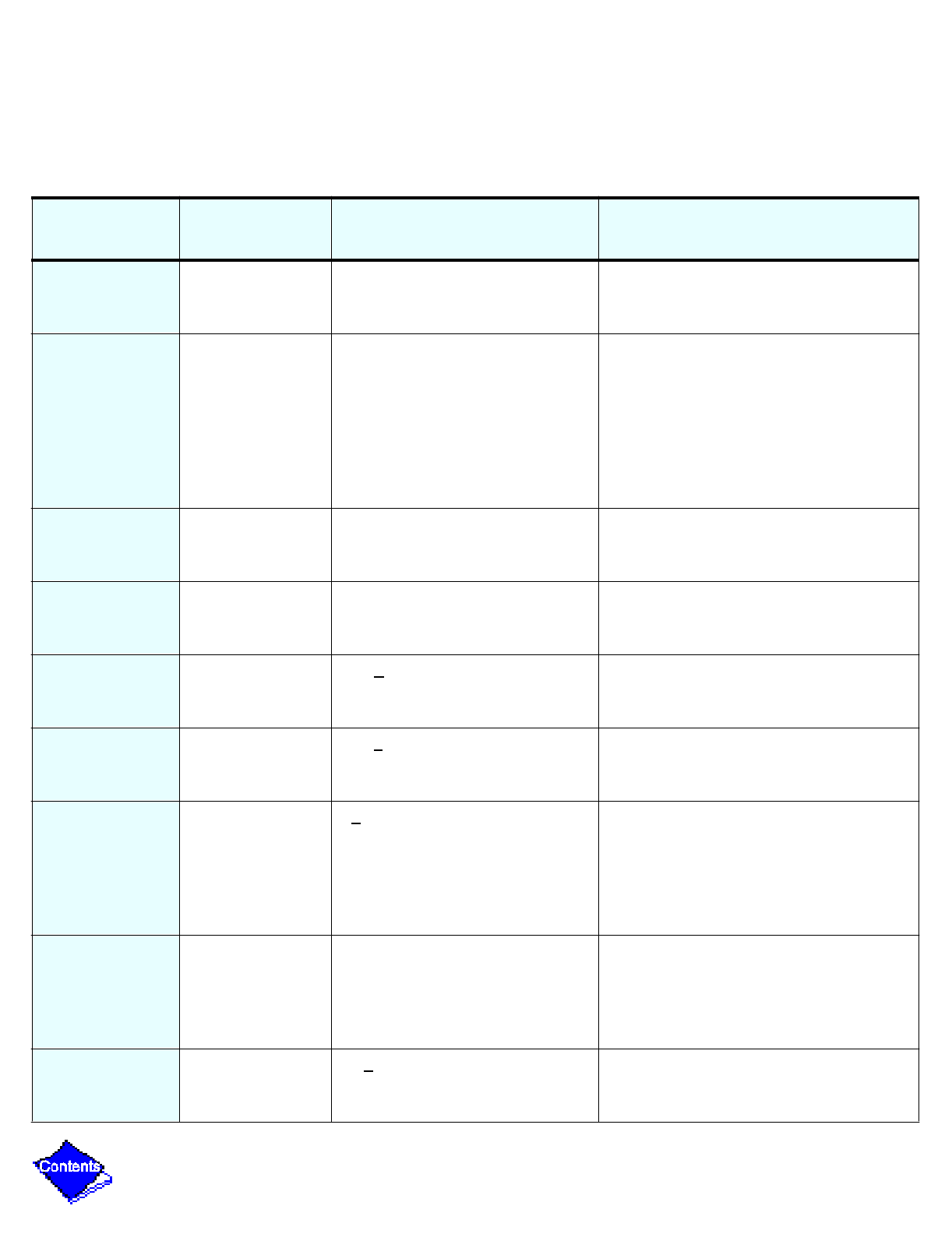

Table 8 — LID Primary and Secondary Messages and Custom Alarm/Alert Messages

with Troubleshooting Guides

F. Start-Up Failures:

This is an alarm condition. A manual reset is required to clear.

Primary

Message

Secondary

Message

Alarm Message/Primary

Cause

Additional Cause/Remedy

Failure To

Start

Low Oil Pressure OILPD [VALUE] exceeded limit

of [LIMIT]*. Check oil pump sys-

tem.

Check for closed oil supply valves.

Check oil filter. Check for low oil tem-

perature. Check transducer accuracy.

Failure To

Start

Oil Press Sensor

Fault

OILPD [VALUE] exceeded limit

of [LIMIT]*. Check oil pressure

sensor.

Check for excessive refrigerant in oil

sump. Run oil pump manually for 5 min-

utes. For hermetic compressors, check

both oil pressure and cooler pressure.

For open-drive units, check calibration

of oil pressure differential amplifier

modules. Check wiring. Replace trans-

ducers if necessary.

Failure To

Start

Low Chilled

Water Flow

EVFL Evap Flow Fault: Check

water pump/flow switch.

Check wiring to flow switch. Check

through Control Test for proper switch

operation.

Failure To

Start

Low Condenser

Water Flow

CDFL Cond. Flow Fault: Check

water pump/flow switch.

Check wiring to flow switch. Check

through Control Test for proper switch

operation.

Failure To

Start

Starter Fault STR FLT Starter Fault: Check

starter for Fault Source.

A starter protective device has faulted.

Check starter for ground fault, voltage

trip, temperature trip, etc.

Failure To

Start

Starter Overload

Trip

STR FLT Starter Overload Trip:

Check amps calibration/reset

overload.

Reset overloads, check ICR relay

before restarting machine.

Failure To

Start

Line Voltage

Dropout

V P Single-Cycle Dropout

Detected: Check voltage supply.

Check voltage supply. Check trans-

formers for supply. Check with utility if

voltage supply is erratic. Monitor must

be installed to confirm consistent,

single-cycle dropouts. Check low oil

pressure switch.

Failure To

Start

High Condenser

Pressure

High Condenser Pressure

[LIMIT]:* Check switch 2C aux,

and water temperature/flow.

Check for proper design condenser flow

and temperature. Check condenser

approach. Check 2C auxiliary contacts

on oil sump starter. Check high pres-

sure switch.

Failure To

Start

Excess Accelera-

tion Time

CA P Excess Acceleration:

Check guide vane closure at

start-up.

Check that guide vanes are closed at

start-up. Check starter for proper opera-

tion. Reduce unit pressure if possible.