Model 500/600

1207 3-15

3-6. REGULAR MAINTENANCE

SCHEDULE

Procedure Frequency

Filtering of shortening Every 3 to 6 frying cycles

Filter pump problem prevention As required

Changing of shortening As required

Changing the filter envelope As required

Cleaning the frypot Before changing the shortening

Cleaning the deadweight valve Daily

Night closing procedures Daily

Check optional rinse hose Weekly

for deterioration

Reversing the lid gasket Quarterly

Lid lubrication Quarterly

Limit stop adjustment Quarterly

Check tightness of spreader bars Quarterly

Clean safety relief valve Annually

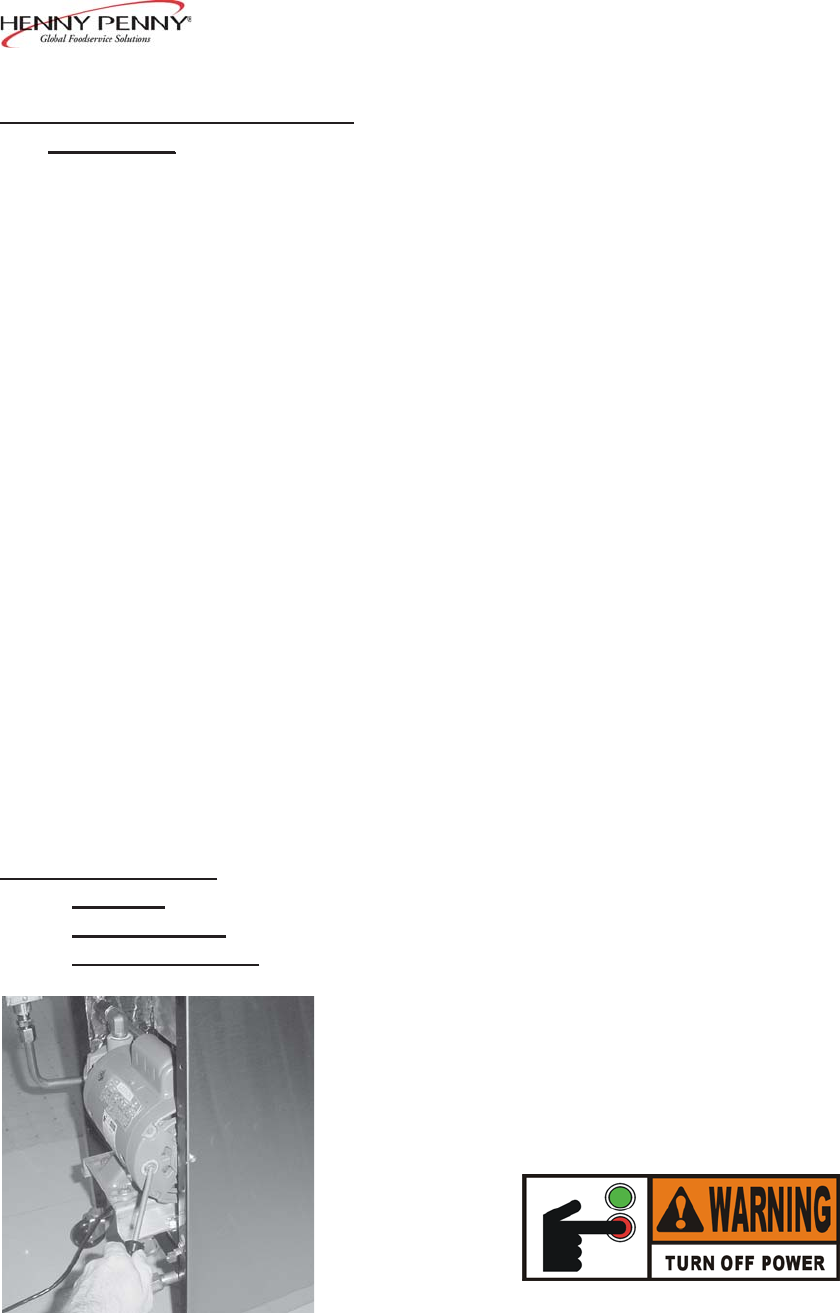

The filter pump motor is equipped with a manual reset button,

located on the rear of the motor, in case the motor overheats. Wait

about 5 minutes before attempting to reset this protective device to

allow motor to cool. The filter motor is on the rear of the fryer. It

takes some effort to push the reset, and a screwdriver can be used to

help reset the button.

Electric fryers with serial numbers of HB013JB & below, and gas

fryers with serial numbers of GA085JB & below, can push the reset

button, by removing the access panel on the left side panel of the unit.

To prevent burns caused by splashing shortening, turn

the unit’s main power switch to the OFF position before

resetting the filter pump motor’s manual reset protection

device.

3-7. FILTER PUMP

MOTOR

PROTECTOR-

MANUAL RESET

As in all food service equipment, the Henny Penny pressure fryer does

require care and proper maintenance. The table below provides a

summary of scheduled maintenance.