T -309 4-2

4.4 C ONNECT REMOTE MONITORING

RECEPTACLE

If remote monitoring is required, connect remote

monitor plug at unit receptacle. (See item 9,Figure 2-5.)

When the remote m onitor plug is connected to the

remote monitoring receptacle, the following remote

circuits are energized:

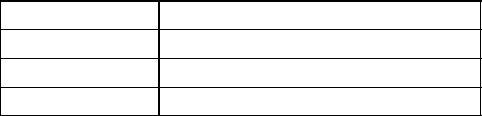

CIRCUIT FUNCTION

Sockets B to A Energizes remote cool light

Sockets C to A Energizes remote defrost light

Sockets D to A Energizes remote in-range light

4.5 STARTING AND STOPPING INSTRUCTIONS

WARNING

Make sur e that the unit circuit breaker(s)

(CB-1 & CB-2) and the START-STOP

switch(ST ) are in the“O”(OFF) positionbe-

fore connecting to any electrical power

source.

4.5.1 Starting the Unit

1. With powerproperly applied, the fresh air damper set

and (if required) the water cooled condenser con-

nected, (refer to paragraphs 4.2 & 4.3) place the

START-STOP switch to “I” (ON).

NOTE

Within the first 30 seconds the electronic phase

detection system will check for proper com-

pressor rotation. If rotation is not correct, the

compressor will be stopped and restarted in the

opposite direction. Ifthe compressor is produc-

ing unusually loud and continuous noise after

the first 30 seconds of operation, stop the unit

and investigate.

2. Continue with Start Up Inspection, paragraph 4.6.

4.5.2 Stopping the Unit

To stop the unit, place the S TART-STOP switch in

position “0” (OFF).

4.6 START--UP INSPECTION

4.6.1 Physical Inspection

a. Check rotation of condenser and evaporator fans.

b. Check compressor oil level. (Refer to paragraph 6.9.)

4.6.2 Check Controller Function Codes

Check and, if required, reset controller Function Codes

(Cd27 through Cd39) in accordance with desired

operating parameters. Refer to paragraph 3.2.2.

DataCORDER

a. Check and, if required, set the DataCORDER Con-

figuration in accordance with desired recording pa-

rameter. Refer to paragraph 3.6.3.

b. Enter a “Trip Start”. To enter a “trip Start”, do the

following:

1. Depress the ALT MODE key and scroll to Code

dC30.

2. Depress and hold the ENTER key for five seconds.

3. The “Trip Start” event will be entered in the Data-

CORDER.

4.6.3 Complete Inspection

Allow unit to run for 5 minutes to stabilize conditions

and perform a pre--trip diagnosis in accordance with the

following paragraph.

4.7 PRE-TRIP DIAGNOSIS

CAUTION

Pre-trip inspection should not be performed

with critical temperature cargoes in the con-

tainer.

CAUTION

When Pre-Trip key is pre ssed, economy, de-

humidification and bulb mode will be deac-

tivated. At the completion of Pre-Trip activi-

ty, economy, dehumidification and bulb

mode must be reactivated.

Pre-Trip diagnosis provides automatic testing of the

unit components using internal measurements and

comparison logic. The program will provide a “PASS”

or “FAIL” display to indicate test results.

The testing begins with access to a pre-trip selection

menu. The user may have the option of selecting one of

two automatic tests. These tests will automatically

perform a series of individual pre--trip tests. The user

may also scroll down to select any of the individual

tests. When only t he short sequenceis configured it will

appear as “AUtO” in the display, otherwise “AUtO1”

will indicate the short sequence and “AUtO2” will

indicate the long sequence. The test short sequence will

run tests P0 through P6. The long test sequence will run

tests P0 through P10.

A detailed description of the pre-trip test codes is listed

in Table 3-7, page 3-21. If no selection is made, the

pre-trip menu selection process will terminate

automatically. However, dehumidification and bulb

mode must be reactivated manually if required.

Scrolling down to the “rSLts” code and pressing

ENTER will allow the user to scroll through the results

ofthe last pre--trip testing run. If no pre--testing hasbeen

run (or an individual t est has not been run) since the unit

was powered up “--------” will be displayed.

To start a pre--t rip test, do the following:

NOTE

1. Priorto startingtests, verifythatunitvoltage

(Function Code Cd 07) is within tolerance

and unit amperage draw (Function Codes

Cd04, Cd05, Cd06) are withi n expected

limits. Otherwise, tests may fail incorrectly.

2. All alarms must be rectified and cleared

before starting tests.