6-17

T -309

Table 6-2 Sensor Temperature/Resistance Chart

(+/--.002%)

Temperature

Resistance

_

__

_C _

__

_F

(Ohms)

C

F

AMBS,

CPSS,

DTS, RTS,

RRS, STS,

SRS

CPDS

-- 3 0 -- 2 2 177,000 1,770,000

-- 2 5 -- 1 3 130,400 1,340,000

-- 2 0 -- 4 97,070 970,700

-- 1 5 5 72,900 729,000

-- 1 0 14 55,330 553,000

-- 5 23 43,200 423,300

0 32 32,650 326,500

5 41 25,390 253,900

10 50 19, 900 199,000

15 59 15, 700 157,100

20 68 12, 490 124,900

25 77 10, 000 100,000

30 86 8,060 80,600

35 95 6,530 65,300

40 104 5,330 53,300

45 113 4,370 43,700

50 122 3,600 36,000

55 131 2,900 29,000

60 140 2,490 24,900

65 149 2,080 20,800

65 158 1,750 17,500

e. Using the plug connector marked “EC”, that is con-

nected to the back of the controller, locate the sensor

wires (RRS, RTS, SRS, STS, AMBS, DTS, CPDS

OR CPSS as required). Follow those wiresto the con-

nector and using the pins of the plug, measure the

resistance. Values are provided in Table 6-2.

Due to the variations and inaccuracies in ohmmeters,

thermometers or other test equipment, a reading

within 2% of the chart value would indicate a good

sensor. If a sensor is defective, the resistance reading

will usually be much higher or lower than the resis-

tance values given.

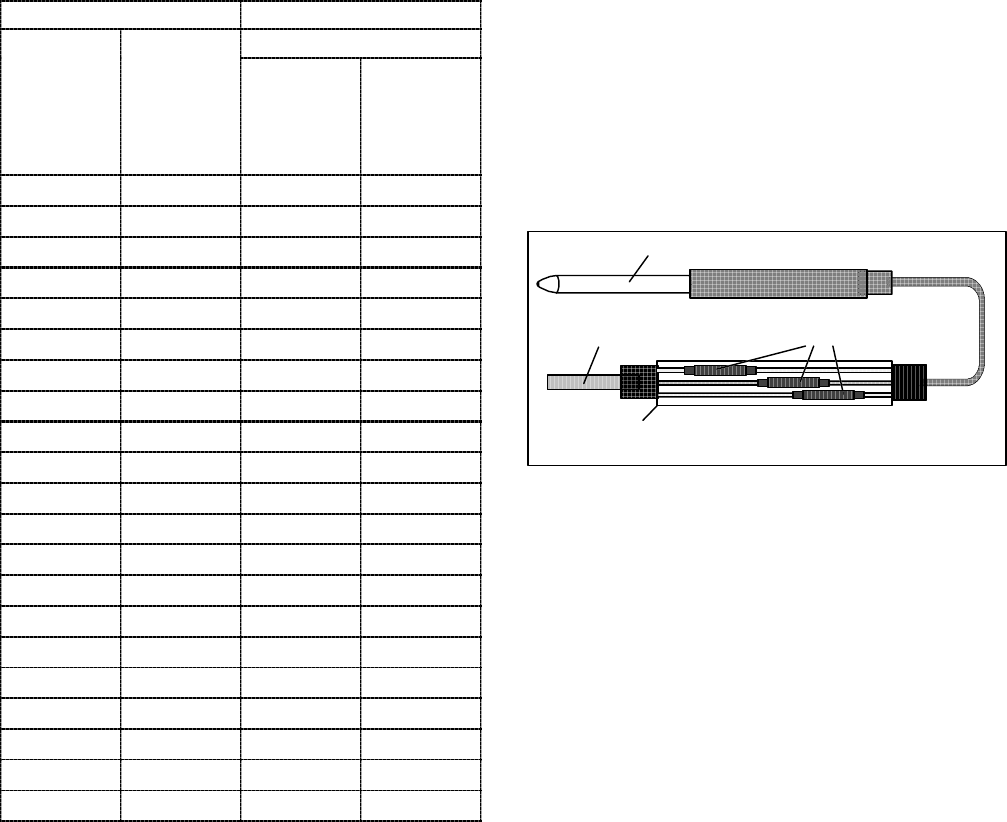

6.22.2 Sensor Replacement

a. Turn unit power OFF, disconnect power supply and

remove sensor assembly from unit.

b. Cut wire(s) 5 cm (2 inches) from shoulder of defec-

tive sensor and discard the defective probe only.

c. Cut one wire of existing cable 40 mm (1-1/2 inch)

shorter than the other wire.

d. Cut one replacement sensor wire (opposite color)

back 40 mm (1-1/2 inch). (See Figure 6-19.)

e. Strip back insulation on all wiring 6.3 mm (1/4 inch).

f. Slide a large piece of heat shrink tubing over the

cable, and place the two small pieces of heat shrink

tubing, one over each wire, before adding crimp fit-

tings as shown in Figure 6-20.

Sensor (Typical)

Cable

Heat Shrink

T ubing (3)

Large Heat Shrink

T ubing (1)

Figure 6-20 Typical Sensor and Cable Splice

g. Slip crimp fittings over dressed wires (keeping wire

colors together). Make sure wires are pushed into

crimpfittingsas faraspossible andcrimpwith crimp-

ing tool.

h. Solder spliced wires with a 60% tin and 40% lead

Rosincore solder.

i. Slide heat shrink tubing over splice so that ends of

tubing cover both ends of crimp as shown in

Figure 6-20.

j. Heattubing to shrink oversplice.Make sureallseams

are sealed tightly against the wiring to prevent mois-

ture.

k. Slide large heat shrink tubing over both splices and

shrink.

CAUTION

Do not allow moisture to enter wire splice

area as this may affect the sensor resistance.

l. Position sensor in unit as shown in m.Figure 6-21

Slip crimp fittings over dressed wires (keeping wire

colors together). Make sure wires are pushed into

crimp fittings as far as possible and crimp with

crimping tool. and re--check sensor resistance.

n. Reinstall sensor, refer to paragraph 6.22.3.

NOTE

The P5 Pre-Trip test must be run to inactivate

probe alarms (refer to paragraph 4.7).