6-12T -309

the refrigeration unit into the container. The fan motor

bearings are factory lubricated and do not require

additional grease.

6.17.1 Replacing The Evaporator Fan Assembly

WARNING

Always turn OFF the unit circuit breakers

(CB-1 & CB-2) and disconnect main power

supply before working on moving parts.

a. Remove upper access panel (see Figure 2-2) by

removing mounting bolts and T.I.R . locking device.

Reach inside of unit and remove the Ty-Rap securing

the wire harness loop. Then unplug the connector by

twisting to unlock and pulling t o separate. NOTE: It

may be easier t o unplug the connector with them otor

assembly partially pulled out (after step b).

b. Remove the four mounting bolts that secure the mo-

tor--fan assembly to the unit.

c. Slide the fan assembly out from the unit and place it

on a sturdy work surface.

d. Remove the motor and fan from the assembly.

e. Replace the motor.

f. Lubricate the fan motor shaft with a graphite--oil

solution (Never--Seez) and apply thread sealer (Loc-

tite H, brown in color) to the two fan set screws.

Installfanon the motorshaft, so thatthe coupling sur-

face will be even with the end of the motor shaft.

g. Install the fan assembly in reverse order of removal.

Apply power momentarily to check for proper fan

rotation (refer to paragraph 2.3). If the fan spins back-

wards, than motor wiring or motor is defective.

Replace access panel making sure that panel does not

leak. Lock--wire the T.I.R. locking device(s).

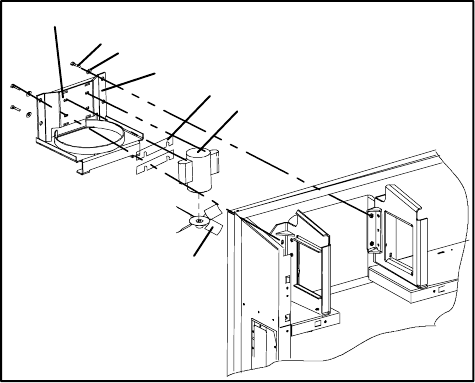

1

2

3

4

5

6

7

8

9

1. Bracket

2. Flat washer, 3/8

3. Bolt, 3/8-16 x 1.00

4. Locknut, 5/16-18

5. Flat washer, 5/16

6. Cap Screw, Hxhd

5/16-18 x 1.25

7. Fan

8. Shim

9. Evaporator Motor

Figure 6-16. Evaporator Fan Assembly

6.18 EVAPORATOR FAN MOTOR CAPACITORS

The evaporator fan motors are of the permanent-split

capacitor type. The motor i s equipped with one

capacitor used in the high speed circuit and another

capacitor used for the low speed circuit.

6.18.1 When To Check For A Defective Capacitor

a. Fan motor will not change speed. For example: in the

conventional perishable mode, the motors should run

in high speed. In the economy perishable mode they

should switch speeds and in thefrozen mode, the mo-

tors should run in low speed.

NOTE

The evaporator fan motors will always start in

high speed.

b. Motor running in wrong direction (after checking

for correct wiring application).

c. Motor will not start, and IP-EM’s are not open.

6.18.2 Removing The Capacitor

WARNING

Make sure power to the unit is OFF and

power p lug disconnected before removing

capacitor(s).

The capacitors are located on the motor and above the

evaporator fan d eck t hey ma y be r emoved by two

methods:

1 If container is empty, open upper rear panel of the

unit. The capacitor may beserviced after disconnect-

ing power plug.

2 If container is full, turn the unit power OFF and dis-

connect power plug. Remove the evaporator fan

motor access panel. (See see Figure 2-1). For

removal of the evaporator fan assembly, refer to sec-

tion 6.17.

WARNING

WithpowerOFFdischargethecapacitorbe-

fore disconnecting the circuit wiring.

6.18.3 Checking The Capacitor

If the capacitor i s suspected of malfunction, you may

choose to simply replace it. Direct replacement requires

a capacitor of the same value. Two methods for

checking capacitor function are:

1. Volt-ohmmeter set on RX 10,000 ohms.

Connect ohmmeter leads across the capacitor terminals

and observe the m eter needle. If the capacitor is good,

the needle will make a rapid swing toward zero

resistance and then gradually swing back toward a very

high resistance reading.

If the capacitor has failed open, the ohmmeter needle

will not move when the meter probes t ouch the

terminals. If the capacitor is shorted, the needle will

swing to zero resistance position and stay there.

2. Capacitor analyzer:

The function of the analyzer is to read the microfarad

value of a capacitor and to detect insulation breakdown