6-9

T -309

2. C heck the moisture-liquid indicator if the indicator

showsa high level ofm oisture, thefilter-driershould

be replaced.

b. To Replace Filter-Drier

1. Pump down the unit (refer to paragraph 6.4 and

replace filter-drier.

2. Evacuate the low side in accordance with paragraph

6.6.

3. After uniti s in operation, inspect for moisture in sys-

tem and check charge.

6.14 EXPANSION VALVES

Two expansion valves are used, the evaporator

expansion valve (item 9, Figure 2-2), and the

economizer expansion valve (item 26, Figure 2-4) .

The

expansion valves are automatic devices which maintain

constant superheat of the refrigerant gas leaving at the

point of bulb attachment regardless of suction pressure.

The valve functions are:

1. Automatic control of the refrigerant flow to match

the load.

2. Prevention of liquid refrigerant entering the com-

pressor.

Unless the valve is defective, it seldom requires

maintenance other than periodic inspection to ensure

thatthe thermal bulb is tightlysecured tothe suctionline

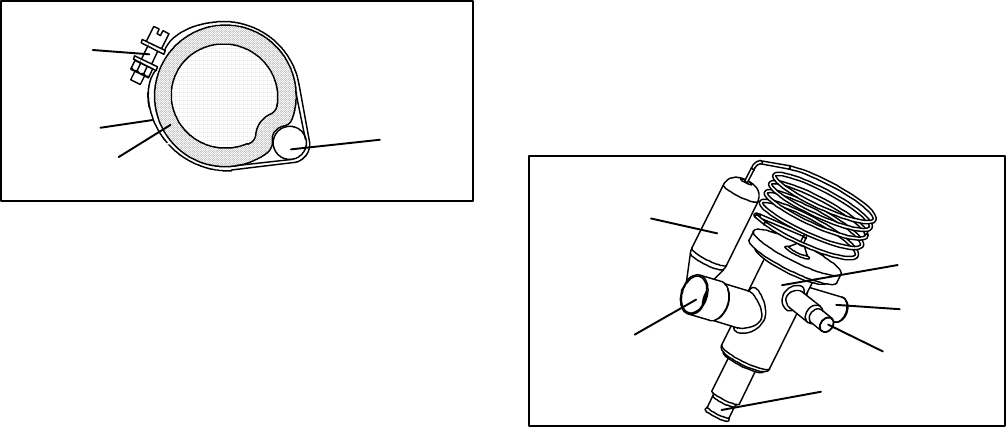

and wrapped with insulating compound. (See

Figure 6-10.)

1

2

3

4

1. Suction Line

2. TXV Bulb Clamp

3. Nut and Bolt

4. TXV Bulb

Figure 6-10 Thermostatic Expansion Valve Bulb

6.14.1 Checking Superheat.

NOTE

Proper superheat measurement for the evapora-

tor expansion valve should be completed at

-- 1 8 _C(0_F) container box temperature where

possible. If the economizer valve is suspect, it

should be replaced.

a. Open the heater access panel (see Figure 2-1) to ex-

pose t he evaporator expansion valve.

b. Attach a temperature sensor near the expansion valve

bulb and insulate. Make sure the suction line is clean

and that firm contact is made with the sensor.

c. Connect an accurate gauge to the service port directly

upstream of the suction modulating valve.

d. Set the temperature set point to --18_C(0_F), and run

unit until conditions stabilize.

e. The readings may cycle from a high to a low reading.

Take readings of temperature and pressure every

three to five minutes for a total of 5or 6 readings

f. From the temperature/pressure chart (Table 6-7), de-

termine the saturation t emperature corresponding to

the evaporator outlet test pressures at the suction

modulation valve.

g. Subtract the saturation temperatures determined in

step f. from the temperatures measured in step e.. The

difference is the superheat of the suction gas. Deter-

mine the average superheat It should be 4.5 to 6.7 °C

(8 to 12 °F)

6.14.2 V alve Replacement

a. Removing the Expansion Valve

NOTES

1. TheTXV’sarehermeticvalvesanddonot

have adjustable superheat.

2. All connections on the evaporato r TXV are

bi---metallic, copper on the inside and

stainless on the outside. When brazing,

bi---metallic connections heat up very

quickly.

1

6

5

4

3

2

1. Evaporator Expansion Valve

2. Non-adjustable Superheat Stem

3. Equalizer Connection

4. Inlet Connection

5. Outlet Connection

6. Expansion Valve Bulb

Figure 6-11 Evaporator Expansion Valve