6-19

T -309

6.24.2 Cracks

Cracks in the control box are repaired using a fiberglass

patch over the damaged area. Materials required are

included in theFiberglassPatchKitsuppliedwithCrack

Repair Kit, Carrier Transicold part number

76-00724-00SV (see Table 6-3).

a. The surface must be clean and dry. Roughen the sur-

face with sandpaper to ensure a good bond.

b. C ut the fiberglass cloth to allow a 25mm (1 --inch)

overlap around the area to be repaired.

c. Stretch and position the cloth over the area to be re-

paired and secure it with masking tape.

d. Make up sufficient epoxy glue to cover the cloth by

mixing equal parts of resin and hardener. Saturate the

cloth with the epoxy glue, spreading evenly.

e. Remove the tape and overlap the edge of the cloth

approximately 6 to 12 mm (1/4” to 1/2”) with glue.

f. Epoxy will dry in 45 --60 minutes. When completely

cured (12 hours), use sandpaper to smooth edges of

the patch.

6.24.3 Chips And Holes

Chips and holes in the control box are repaired using a

piece of aluminum or stainless steel to cover the

damaged area. Thematerial canbe cutto suit andriveted

in place. An adhesive sealant must be used to make the

repair watertight. The adhesive sealant (Sikaflex 221) is

included in Crack Repair Kit Carrier Transicold part

number 76-00724-00SV (see Table 6-3). Do not use an

acetone b ased silicone sealant (Which can be

identified by a vinegar--like odor).

a. To make up the patch, cut a piece of aluminum or

stainless steel so that it will overlap the damaged area

by at least 40 mm (1 1/2”) on all sides.

b. Choose rivet locations and drill the rivet holes in the

corresponding locations on the control box and patch

piece.

c. Apply the adhesive sealant around the damaged area

to form a seal between the control box and the patch

piece.

d. Rivet the patch piece in place.

e. File smooth any rough edges (including rivets) that

may come i nto contact with wires.

6.24.4 Inserts

The threaded brass inserts that are molded into the

control box will need to be replaced if t he threads

become stripped, or if the insert becomes loose. The

inserts and epoxy are contained in repair kit, Carrier

Transicold part number 76-50084-00 (see Table 6-4).

There are 6 different inserts used in the control box.

Refer to Figure 6-24 for the locations of the various

inserts.

NOTE

An epoxyapplicationgun isalso needed,Carri-

er Transicold part number 07 -- 00391 -- 00.

The damaged insert must be removed from the control

box. Table 6-5 identifies the drill size and drill depth to

beused for eachinsert. A stop ring should beused on the

drill bit to limit the depth.

a. Center the drill bit on the insert and drill to the pre-

scribed depth.

b. Remove the chips from the drilled hole.

c. Mix the two component epoxy and fill the hole 1/2

way to the top with epoxy.

d. Press the insert in until it is flush with the surface.

e. Wipe away any excess epoxy. The part is ready for

service after the bond material has hardened and is

tack free (approximately 20 minutes)

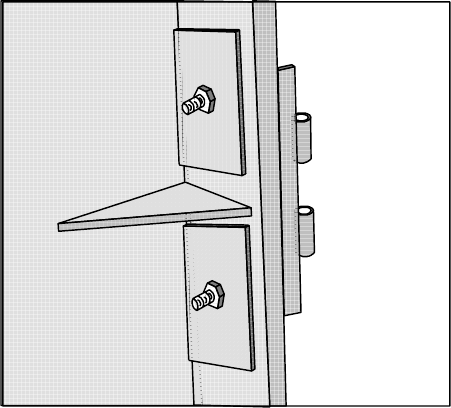

6.24.5 Door Hinge Inserts

If the door hinges have been pulled from the control box

drill and reinstall the hingeas shown in Figure 6-23 and

described in the following steps.

Figure 6-23 Door Hinge Repair

Materials needed:

1. Cut two square pieces of 3 mm thick (1/8 inch) alu-

minum or stainless steel approximately 40 mm (1

5/8”) square. These squares will serve as backing

plates.

2. Two nuts, bolts (10 -- 24 x 1”) and washers for each

insert that needs repair.

a. Drill a 1/4” hole in the center of each square backing

plate.

b. Pass the bolts through the bolts holes in the door

hinge, then through the control box at the l ocation

where the hinge insert pulled out.

c. From inside the control box, slide the backing plates

over the bolts and secure in place with the washers

and nuts.