6-13

T -309

under load conditions. The important advantages of a

analyzer are its ability to locate capacitors that have

failed to hold their microfarad ratings, or those t hat are

breaking down internally during operation. It is also

useful in identifying capacitors when their microfarad

rating marks have become unreadable.

6.19 VALVE OVERRIDE CONTROLS

CAUTION

DO NOT disassemble piston from NEW suc-

tion modul ating valve powerhead assembly.

Doing so may result in damage to piston.

Controller function code Cd41 is a configurable code

that allows timed operation of the automatic valves for

troubleshooting.Three testsequencesare provided.The

first, capacity mode (CAP), allows alignment of the

unloader and economizer solenoid valves in the

standard, unloaded and economized operating

configurations. The second, SMV % Setting (SM)

allows opening of the suction m odulating valve to

various percentages and the third, Oil Valve Setting

(OIL) andLiquid Valve Setting (LIV)allows opening or

closing of t he oil return solenoid valve and the liquid

injection solenoid valve. A fourth selection is also

provided to enter a time period of up to three minutes,

during which the override(s) are active. If the timer is

active, valve override selections will take place

immediately. If the timer is not active, changes will not

take place for a few seconds after the timer is started.

When the timer times out, override function is

automatically terminated and the valves return to

normal machinery control. To operate the override, do

the following:

a. Press theCODE SELECT key then press anARROW

key until Cd41 is displayed in the left window. The

right window will display a controller communica-

tions code.

b. Press t he ENTER key. The left display will show a

test name alternating with the test setting or time re-

maining. Use an ARROW key to scroll to the desired

test. Press the ENTER key and SELCt will appear in

the left display.

c. Use an ARROW key to scroll to the desired setting,

and then press the ENTER key. Selections available

for each of the tests are provided in the following

table.

d. If the timer is not operating, follow the above proce-

dure to display the timer. Use an ARROW key to

scroll to thedesiredtime interval and press ENTER to

start the timer.

e. The above described sequence may be repeated dur-

ing the timer cycle to change to another override.

Right Display A vailable Selections

CAP

(Capacity Mode)

AUtO

(Normal Control)

(

p

y

)

UnLd

(Unloader = Open

Economizer = Closed)

Std

(Unloader = closed

Economizer = closed)

ECOn

(Unloader = closed

Economizer = open)

SM

(SMV % Setting)

AUtO

(Normal Control)

0

3

4

6

12

25

50

100

OIL

(Oil Valve Setting)

AUto

(Normal Control)

(

g

)

CLOSE

OPEn

LIV

(Liquid Valve Setting, if

l

i

b

l

)

AUto

(Normal Control)

(

q

g

,

applicable)

CLOSE

OPEn

tIM

(Timer)

000(0 minutes/0 Seconds)

In 30 second increments to

300(3 minutes/ 0 seconds)

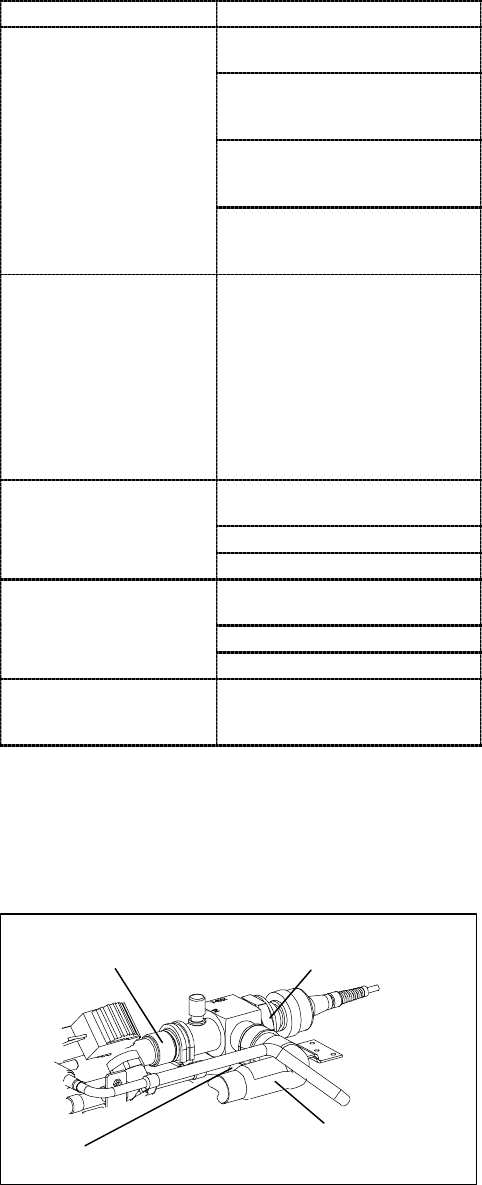

6.20 SUCTION MODULATION VALVE

On start up of the unit, the valve will reset to a known

open position. This is accomplished by assuming the

valve was fully open, driving it fully closed, resetting

the percentage open to zero, then opening to a known

10% staging position.

2-1/8 inch Nut

FROM COIL

FROM UNLOADER

TO COMPRESSOR

Figure 6-17 Suction Modulation Valve (SMV)